Double-motor stirrer capable of adjusting humidity of mixture and humidity adjusting method

A mixture and dual-motor technology, applied in chemical instruments and methods, cement mixing devices, batching and batching instruments, etc., can solve the problem of not being able to adjust the humidity value of the mixture in real time, and achieve the effect of reducing the heat of stirring and increasing the heat of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

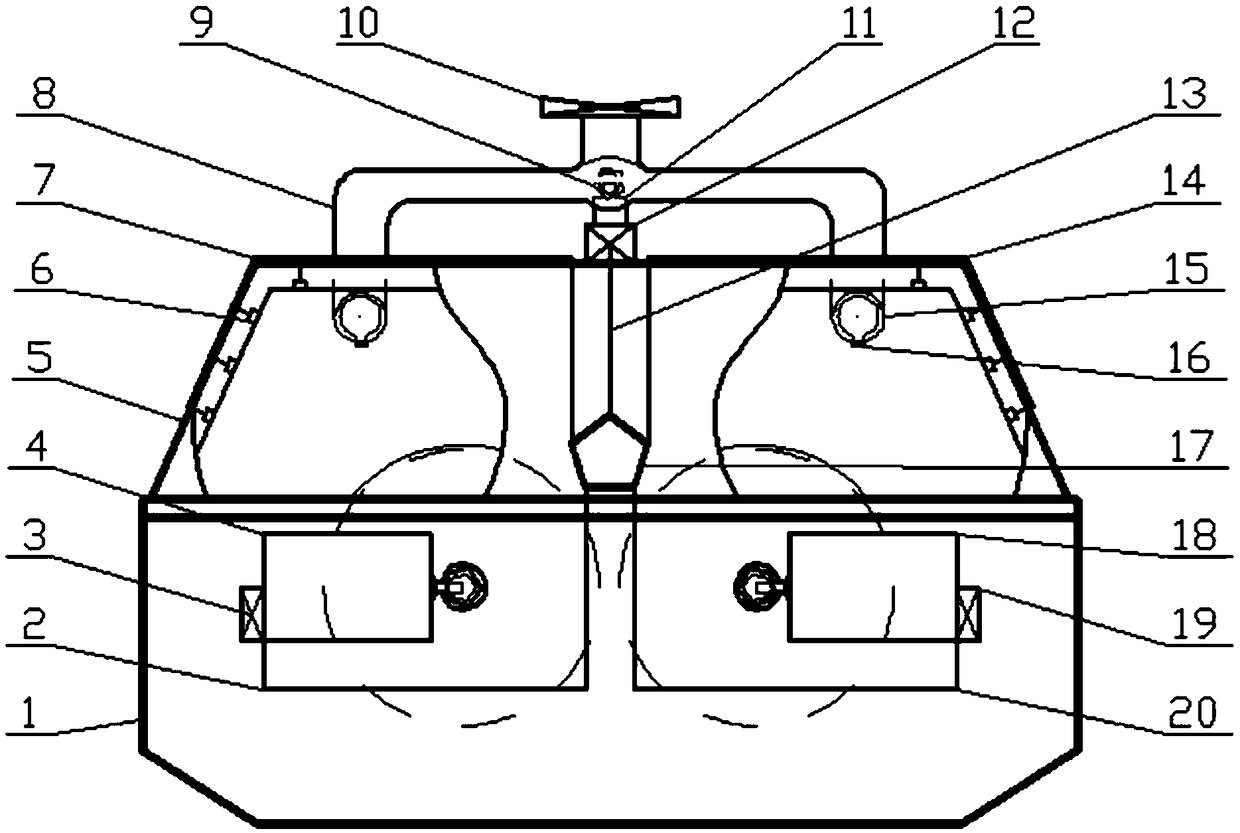

[0026] Such as figure 1 Shown is an embodiment of a dual-motor stirrer that can adjust the humidity of the mixture of the present invention, including a mixing box formed by the docking of the main box body 1 and the box cover plate 5 to form a closed stirring inner cavity, and is arranged in the mixing box External first main motor 4, second main motor 18, said first main motor 4, second main motor 18 are respectively provided with stirring shafts, and said stirring shafts enter the stirring tank through the tank wall of said stirring tank The inner cavity of the mixing tank is provided with a humidity sensor 6 for detecting the humidity of the mixture and a spray pipe 15 for humidifying the mixture. The spray pipe 15 is provided with a number of spray holes 16, The spray pipe 15 communicates with the main liquid pipeline 8 arranged outside the mixing tank, and the main liquid pipeline 8 is provided with a liquid pump 9 for supplying liquid to the spray pipe 15. The first Th...

Embodiment 2

[0037] A method for adjusting the humidity of the mixture using the dual-motor agitator capable of adjusting the humidity of the mixture in Embodiment 1, comprising the following method steps:

[0038] Step 1. Adding material and closing the cover: put the mixture into the mixing box, and close the cover after adding the material;

[0039] Step 2, humidity value setting: set the lower limit (for lower humidity) and upper limit (for higher humidity) of the humidity value of the mixture;

[0040] Step 3, start stirring: the humidity value of the mixture is detected by the humidity sensor 6 during the stirring process. When the detected humidity value is lower than the lower limit set, the liquid pump 9 is turned on, and the liquid is sprayed out through the spray pipe 15, and the mixture is sprayed. Humidification; when the detected humidity value exceeds the upper limit set, the liquid pump 9 is turned off, and the humidification of the mixture is stopped.

[0041] As a furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com