Blanking execution mechanism of automatic feeding mechanism

A technology of automatic feeding and actuators, which is applied in packaging and other directions, to achieve the effect of reducing cost, reducing space occupancy, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

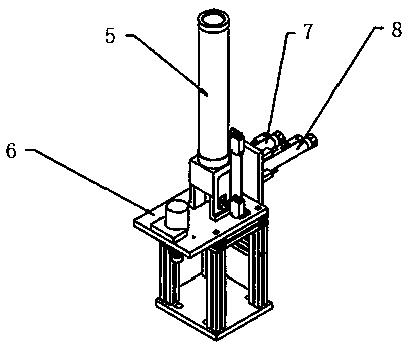

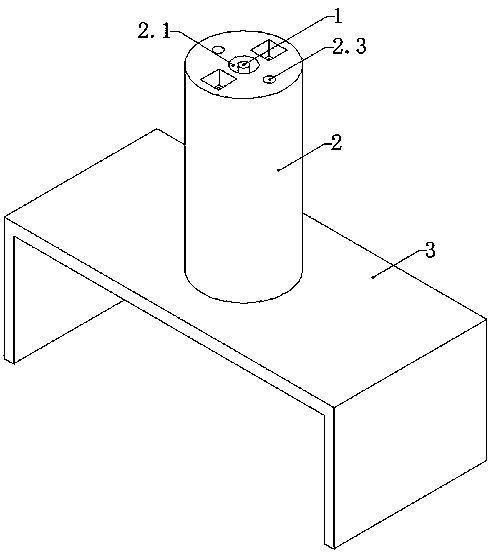

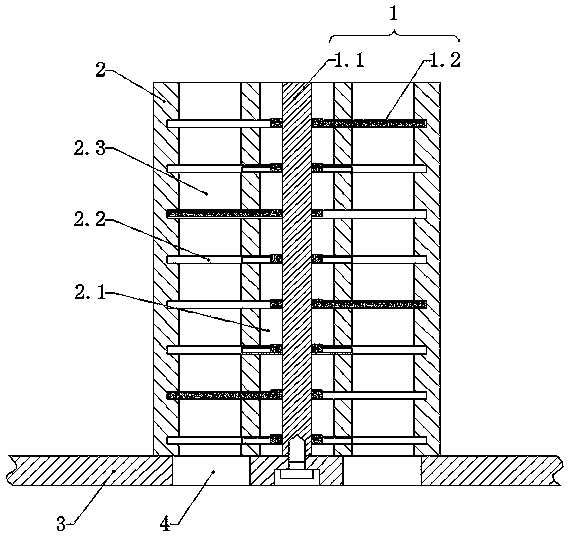

[0032] Such as Figure 2-3The blanking actuator of an automatic feeding mechanism shown includes a screw distributing shaft 1.1 assembly 1, and the screw distributing shaft 1.1 assembly 1 includes a distributing shaft 1.1 and a mutual cooperation set on the distributing shaft 1.1 at intervals. Two spiral receiving units, the spiral receiving unit includes four receiving fan pieces 1.2 arranged in a 360° radial spiral, and the four receiving fan pieces 1.2 are enclosed in a circle or ring shape; it also includes a material guide 2. The material guide 2 has a shaft channel 2.1 for accommodating the distributing shaft 1.1 and eight fan channels 2.2 for accommodating the rotation of two screw receiving units, as well as a corresponding receiving fan for the screw receiving unit 1.2 Matching four blanking channels 2.3, each blanking channel 2.3 respectively intersects with eight fan channels 2.2; wherein, the screw distribution shaft 1.1 component 1 is rotationally connected with t...

Embodiment 2

[0048] A blanking actuator of an automatic feeding mechanism, comprising a screw distributing shaft 1.1 assembly 1, the screw distributing shaft 1.1 assembly 1 includes a distributing shaft 1.1 and two interfitting mutually arranged distributing shafts 1.1 A spiral receiving unit, the spiral receiving unit includes four receiving fans 1.2 arranged in a 360° radial spiral, and the four receiving fans 1.2 are enclosed in a circle or ring shape; it also includes a material guide 2, the The material guide 2 has a shaft passage 2.1 for accommodating the distribution shaft 1.1 and eight fan passages 2.2 for accommodating the rotation of two spiral receiving units, and is used to cooperate with the corresponding receiving fans 1.2 of the spiral receiving unit There are four blanking channels 2.3, and each blanking channel 2.3 intersects with eight fan channels 2.2 respectively; wherein, the screw distribution shaft 1.1 assembly 1 is rotatably connected with the material guide 2.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com