Fine sodium modification method and device for bentonite

A technology of sodium modification and bentonite, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of high cost, large investment, and less use of actual production, and achieve stable product performance and sufficient sodium reaction. , good effect of modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

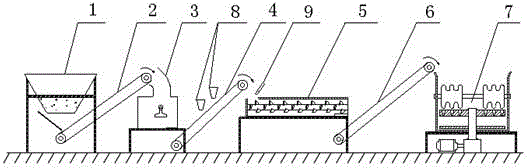

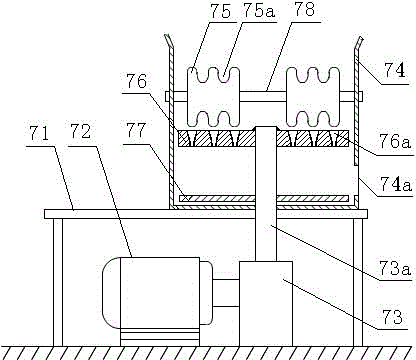

[0025] The following examples will further illustrate the present invention in conjunction with the accompanying drawings.

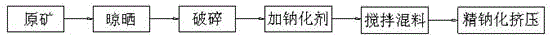

[0026] see figure 1 , a bentonite refined sodium modification method, comprising the following process steps and process parameters:

[0027] 1. Raw ore is dried. Put the calcium-based bentonite raw ore in the drying yard for drying and removing impurities, and control the moisture content of the raw ore after drying to ≤22%.

[0028] 2. Crushing and sorting. The raw ore after drying and removing impurities is crushed by a hammer crusher. A screen with an aperture of Φ20mm is installed at the bottom of the crusher to crush and sieve mineral materials with a particle size of ≤20mm for future use.

[0029] 3. Stir the mixture. Convey the mineral material to the screw mixer. During the conveying process, the vibrating feeder drives the sodiumizing agent hopper to vibrate and add sodium carbonate powder and sodium fluoride powder. The amount of sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com