A production method of an improved decorative panel

A production method and technology for decorative panels, applied in the field of decorative materials, can solve the problems of wasting manpower, material and financial resources, and the decorative panels are not ideal in terms of fire resistance, sound insulation and heat preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

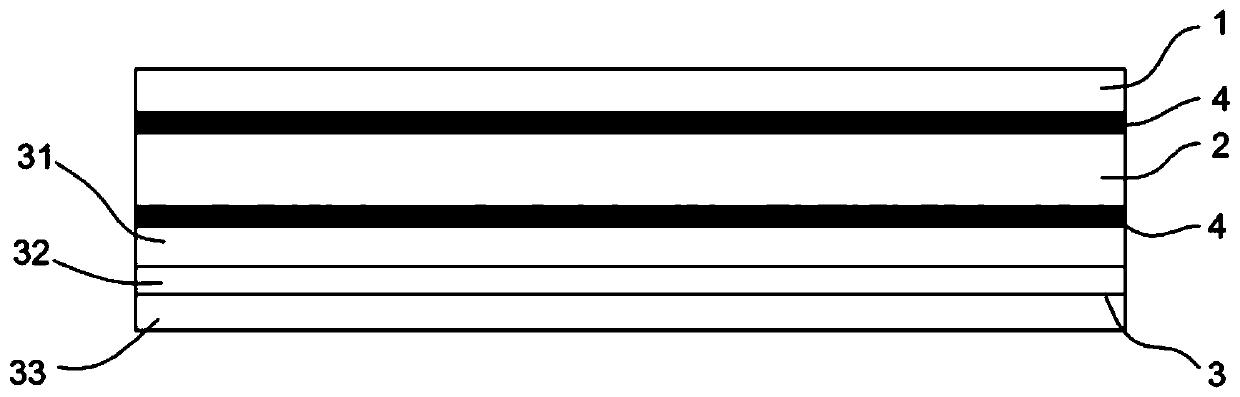

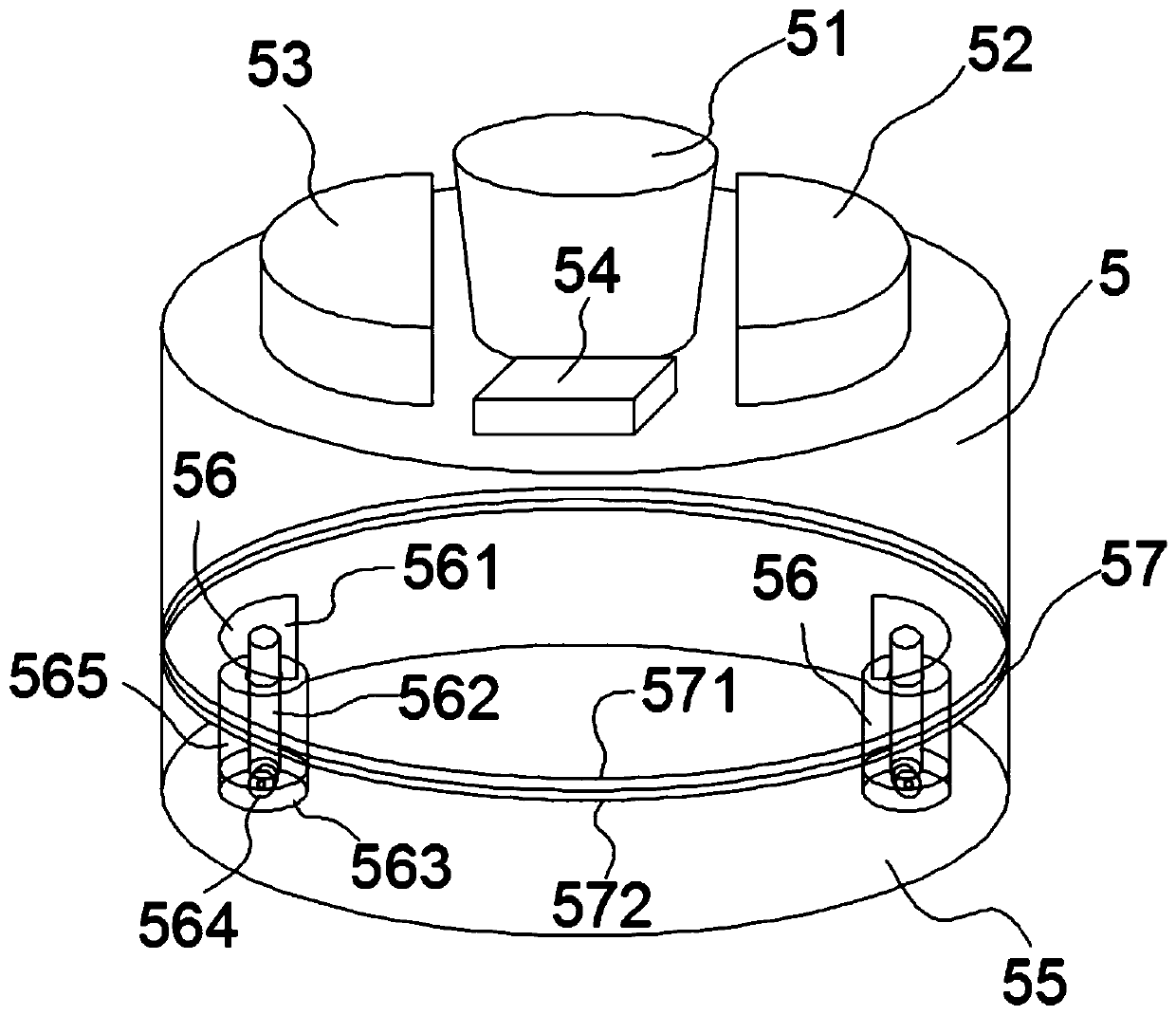

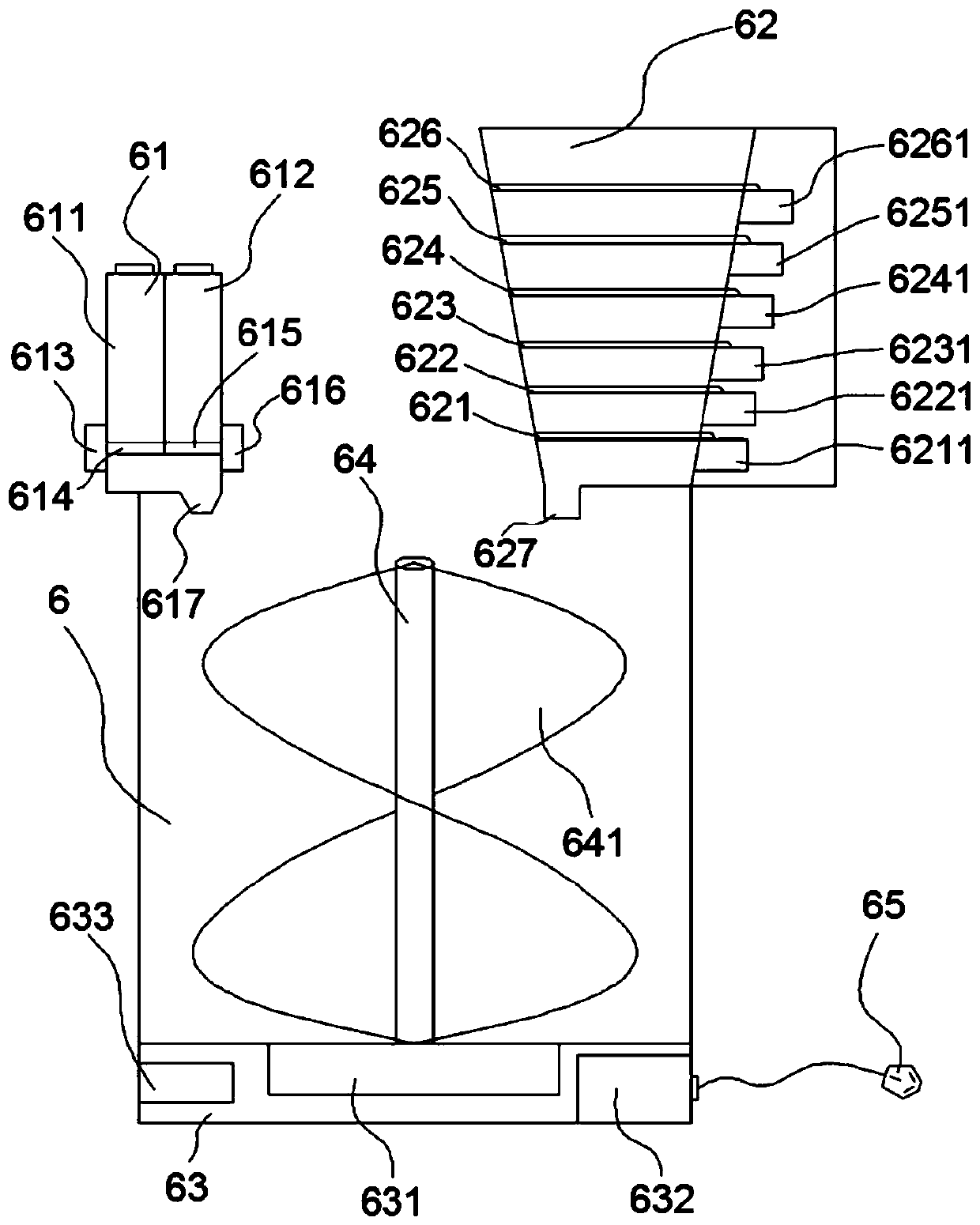

[0036] An improved production method of a decorative board, the decorative board includes a decorative layer 1, an impact layer 2, a composite layer 3 and an adhesive layer 4, the decorative layer 1, the impact layer 2 and the composite layer 3 are arranged in sequence from top to bottom, every two Adhesive layer 4 is evenly distributed between the layers, and it is extruded by a pressure of 1200N to obtain a decorative plate. The decorative layer 1 is a hard finish such as stone, ceramic sheet, inorganic decorative veneer; the impact layer 2 is from top to bottom The metal layer, the adhesive layer and the ACF artificial cartilage foam layer are in sequence. The adhesive layer is located between the metal layer and the ACF artificial cartilage foam layer. The pressure of 320N is used to integrate them together in turn. The metal layer can effectively fix the shape of the impact layer. ACF The artificial cartilage foam layer can greatly cushion the impact force, and compared wi...

Embodiment 2

[0043] An improved production method of a decorative board, the decorative board includes a decorative layer 1, an impact layer 2, a composite layer 3 and an adhesive layer 4, the decorative layer 1, the impact layer 2 and the composite layer 3 are arranged in sequence from top to bottom, every two Adhesive layer 4 is evenly distributed between the layers, and it is extruded by a pressure of 1200N to obtain a decorative plate. The decorative layer 1 is a hard finish such as stone, ceramic sheet, inorganic decorative veneer; the impact layer 2 is from top to bottom The metal layer, the adhesive layer and the ACF artificial cartilage foam layer are in order. The adhesive layer is located between each two layers, and they are integrated together with a pressure of 320N. The metal layer can effectively fix the shape of the impact layer, and the ACF artificial cartilage foam layer It can greatly buffer the impact force. Compared with other materials, the impact resistance is better;...

Embodiment 3

[0050] An improved production method of a decorative board, the decorative board includes a decorative layer 1, an impact layer 2, a composite layer 3 and an adhesive layer 4, the decorative layer 1, the impact layer 2 and the composite layer 3 are arranged in sequence from top to bottom, every two Adhesive layer 4 is evenly distributed between the layers, and it is extruded by a pressure of 1200N to obtain a decorative plate. The decorative layer 1 is a hard finish such as stone, ceramic sheet, inorganic decorative veneer; the impact layer 2 is from top to bottom The metal layer, the adhesive layer and the ACF artificial cartilage foam layer are in order. The adhesive layer is located between each two layers, and they are integrated together with a pressure of 320N. The metal layer can effectively fix the shape of the impact layer, and the ACF artificial cartilage foam layer It can greatly buffer the impact force. Compared with other materials, the impact resistance is better;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com