Blade-type pneumatic motor

An air motor and vane-type technology, which is applied in the field of vane-type air motors, can solve the problems of position deviation between the rotation axis and the center of gravity of the motor, increased manufacturing costs, and poor overall stability, so as to increase output torque, reduce vibration, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

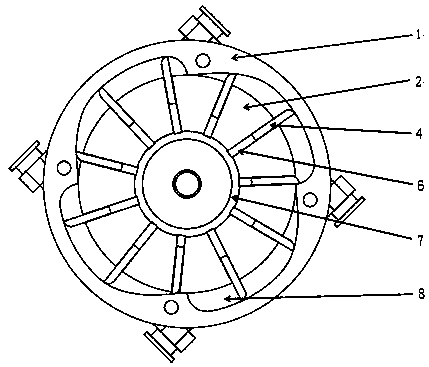

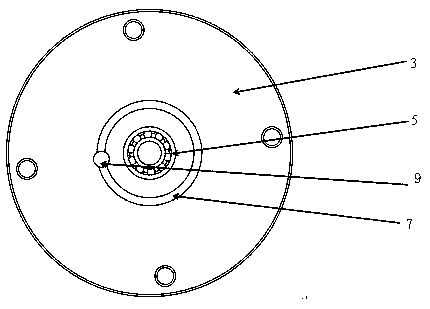

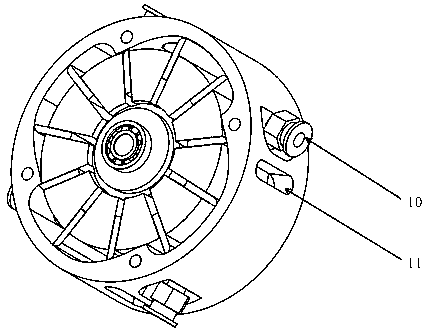

[0031] The optimal implementation mode: if Figure 1-3 A vane-type air motor is shown, including a housing 1, an end cover 3 and a rotor 2, the housing 1 and the end cover 3 are coupled and connected to form a rotor installation cavity between the two, the rotor is installed in the rotor installation cavity and One end in the axial direction of the rotor is the rotation output end, and the circumferential edge of the rotor 2 is provided with blade grooves 6 along the diameter direction, and the blade grooves 6 are distributed in the circumferential direction of the rotor 2, and blades 4 are slidably arranged in the blade grooves 6; its improved The point is that the rotor 2 and the rotor installation cavity are coaxially arranged, and the circumferential side wall of the rotor installation cavity is concaved outward to form a working chamber 8 for supplying airflow to push the blades to do work. The outer wall of the working chamber 8 is smooth Curved shape, the length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com