Production line data automatic acquisition system and method

A production line data and automatic collection technology, applied in the direction of data processing applications, instruments, resources, etc., can solve problems that are easy to cause errors, affect production efficiency, and take up a lot of time for aging tests, so as to improve speed and reduce the risk of error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

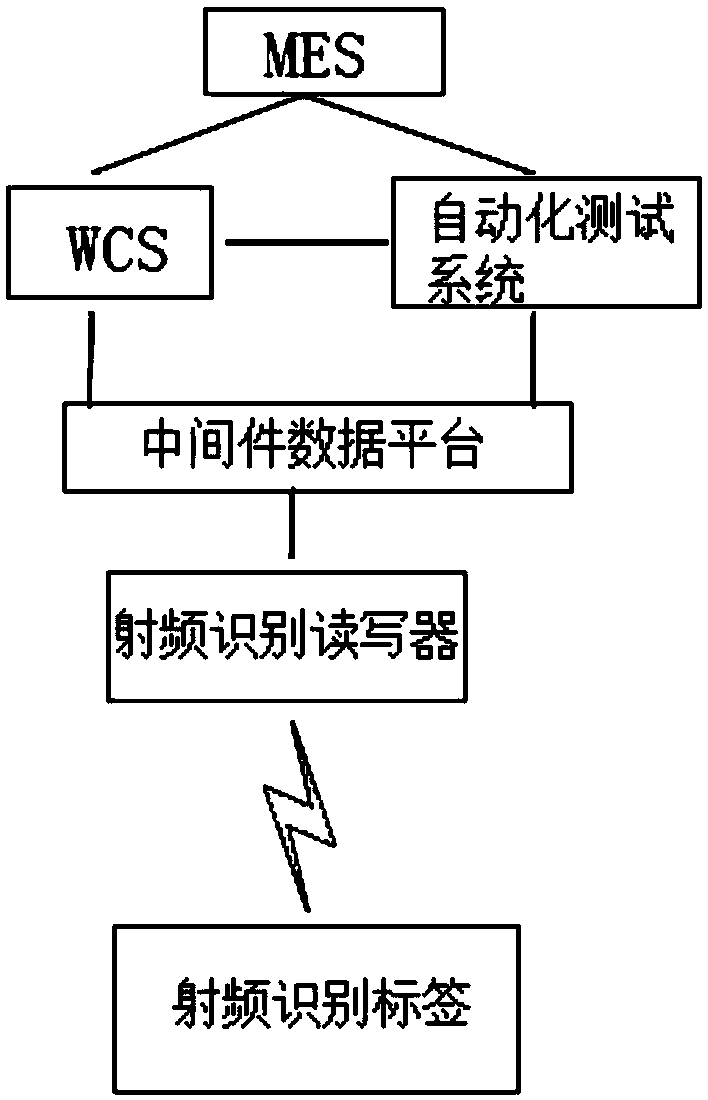

[0026] Such as figure 1 As shown, the overall structure of the system of the present invention includes: a radio frequency identification tag attached to the material pallet, mainly recording product information on the material pallet; a radio frequency identification reader-writer communicating with the radio frequency identification tag to read information; performing data processing and analysis Middleware data platform; MES, WCS, automated test system and other applications that provide application services.

[0027] The radio frequency identification tag mainly records the information of the corresponding product on the material pallet. When passing through the station equipped with a radio frequency identification reader, the radio frequency identification reader reads the label information and uploads it to the middleware data platform. The uploaded information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com