A fully automatic polarity discrimination method for surface-mounted capacitor mounting and welding based on image analysis

A technology of image analysis and polarity discrimination, applied in the field of electronic information, can solve the problems of reducing system flexibility and difficulty in fully automatic, and achieve the effect of improving the level of intelligence and autonomy, reducing labor costs, and realizing fully automatic discrimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

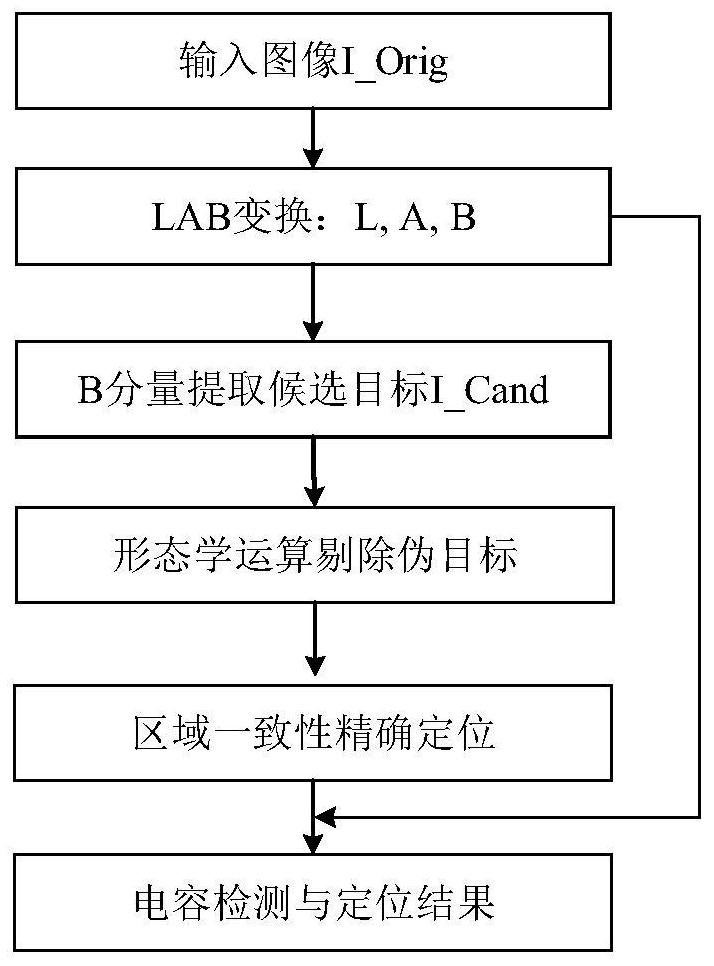

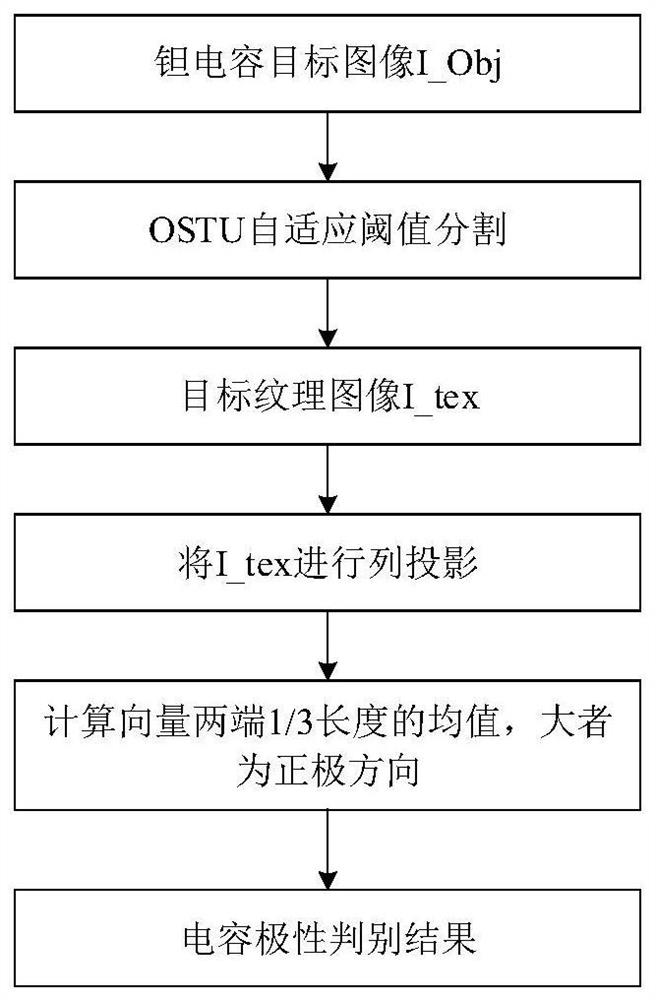

Method used

Image

Examples

Embodiment 1

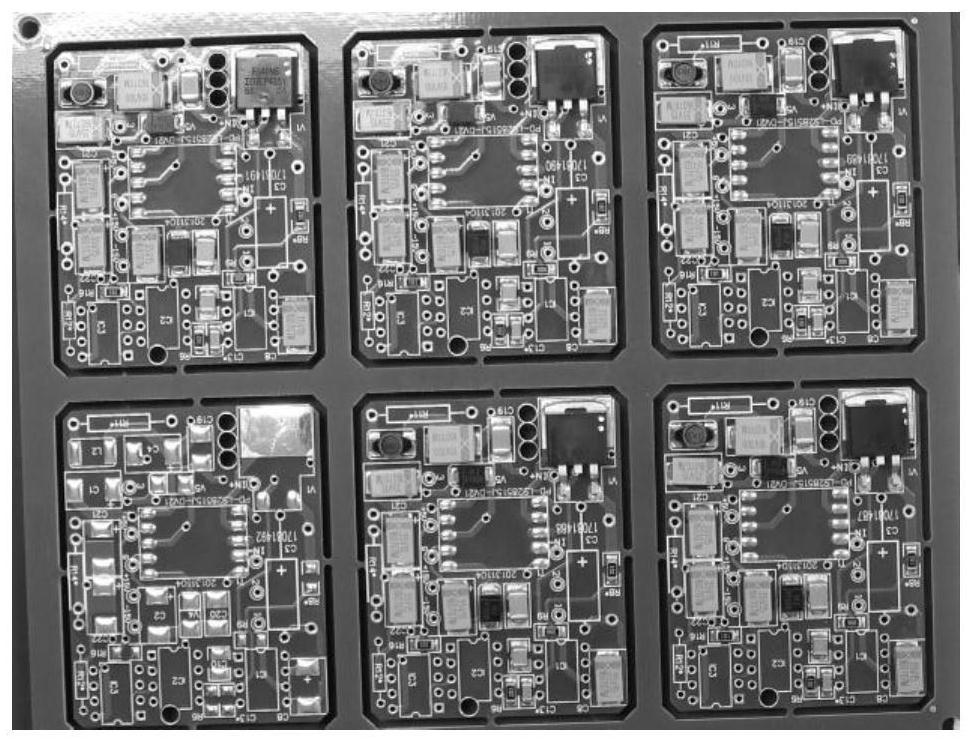

[0078] Input the board image as image 3 As shown, the light intensity in the upper left corner is significantly greater than that in the lower right corner, and the orientation of the capacitors is inconsistent. The image of the target area of the circuit board obtained by using the LAB space color feature and area consistency detection is as follows: Figure 4 shown.

[0079] Figure 5 It is the detection and positioning results of the tantalum capacitor target in the original image. It can be seen that the algorithm of the present invention can realize accurate detection and positioning under the conditions of inconsistent illumination and inconsistent orientation. Using the algorithm of the present invention to Figure 4 The result of polarity judgment of the detected capacitance is as follows: Figure 6 As shown, the end of the capacitor with the black strip is the positive pole. The result of the algorithm discrimination is the orientation of the positive pole of t...

Embodiment 2

[0081] Input the board image as Figure 7 As shown, due to the large area of the circuit board, the clarity of the capacitor texture in the captured image is not high, and the size of the capacitors varies greatly, and the orientation is also inconsistent. The image of the target area of the circuit board obtained by using the LAB space color feature and area consistency detection is as follows: Figure 8 shown. The detected regions and locations are marked in the original image as Figure 9 shown by Figure 9 It can be seen that the algorithm of the present invention accurately detects the position and area of the tantalum capacitor. The polarity discrimination results of the detected capacitance are as follows: Figure 10 As shown, the correct polarity discrimination rate of the present invention reaches 100%, and the entire detection and discrimination process is less than 5 seconds, which is less than 1 / 100 of manual labor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com