Combiner fixing frame suitable for narrow object

The technology of a combiner and a fixing frame is applied in the field of auxiliary auxiliary devices of the combiner, which can solve the problems of inability to install the combiner, and achieve the effects of simple structure, low manufacturing cost and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

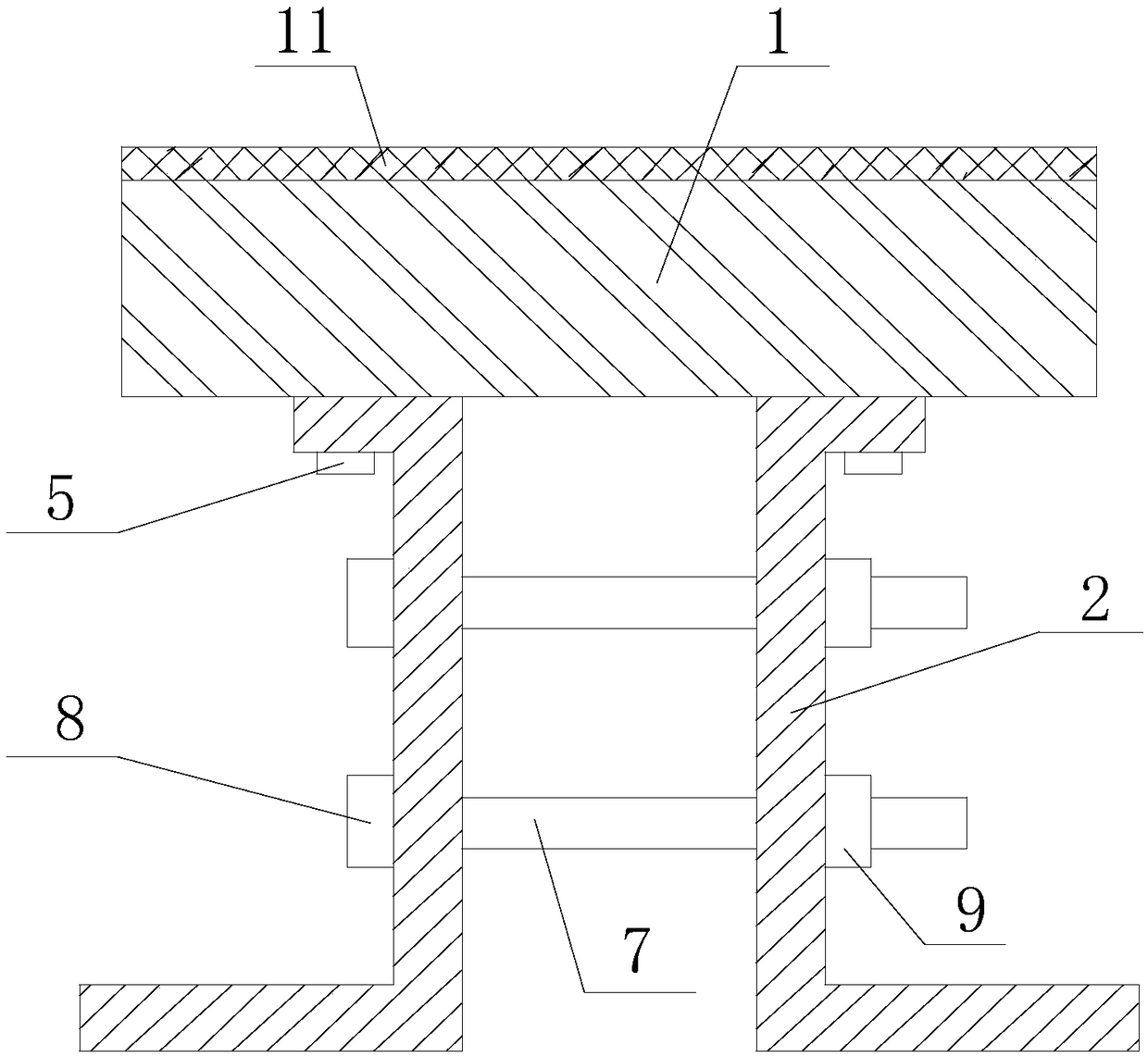

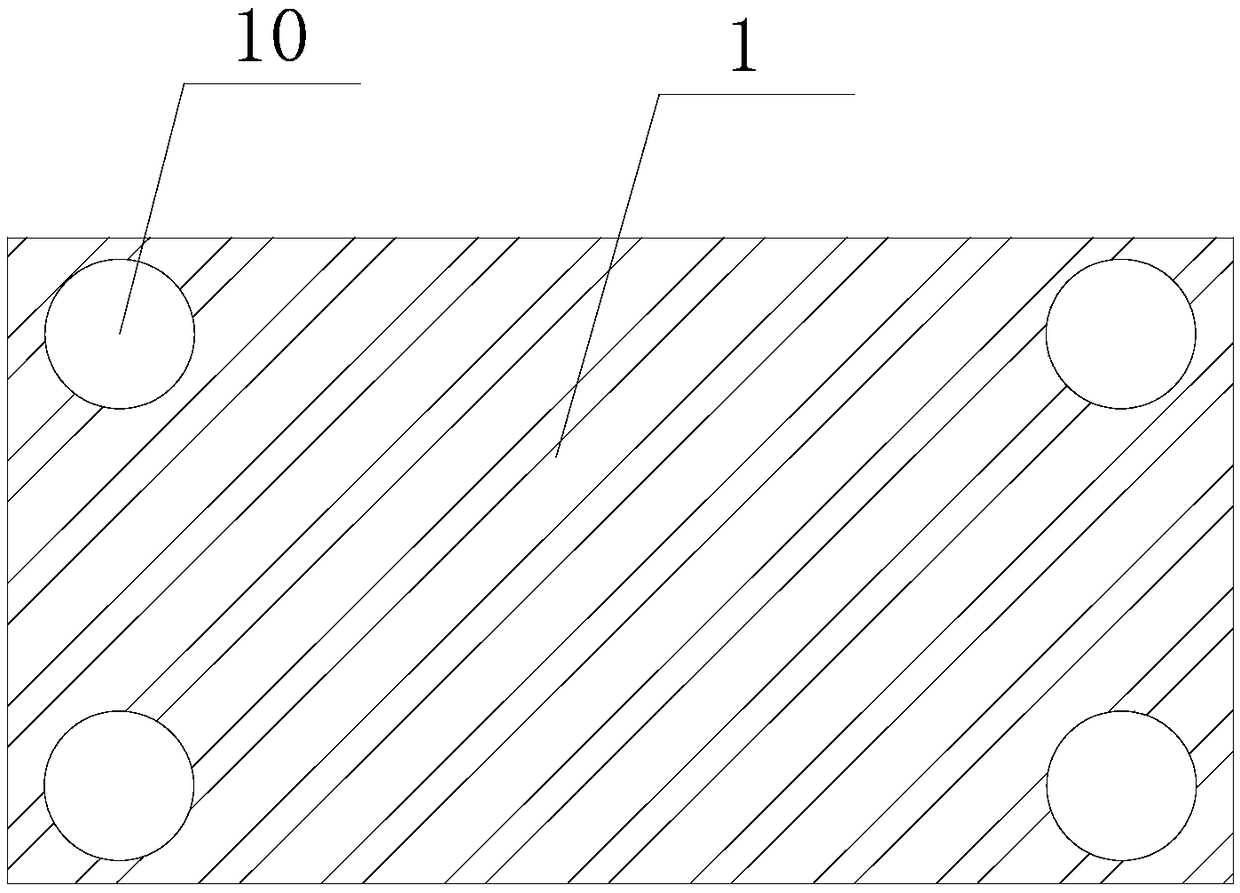

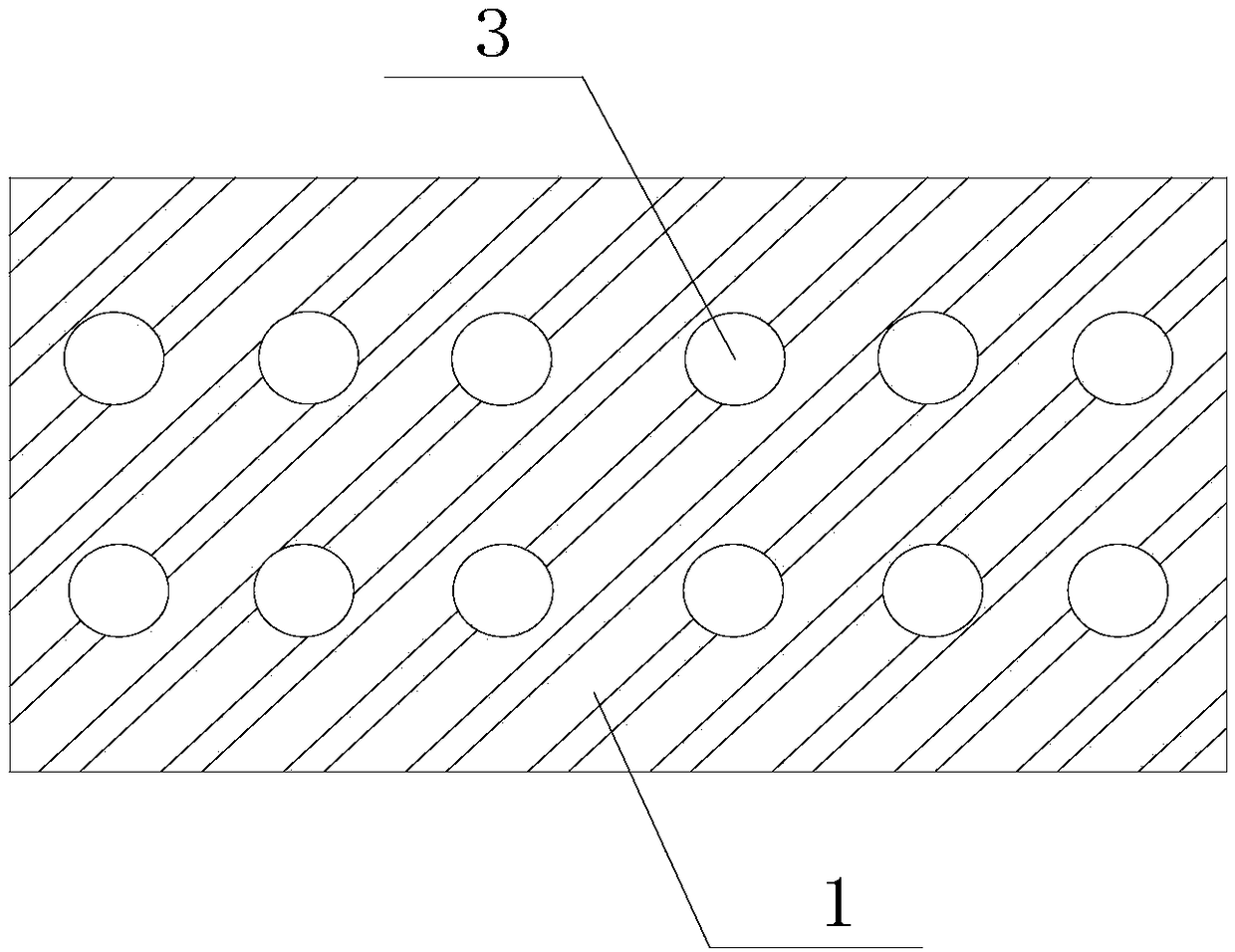

[0024] Such as Figure 1-4 As shown, the combiner fixing frame suitable for narrower objects includes a fixed table 1 and a mounting plate 2, the top of the fixed table 1 is provided with a first blind hole 10, and the bottom of the fixed table 1 is provided with a number of second blind holes. The blind holes 3 and the second blind holes 3 are evenly distributed at equal intervals along the length direction of the bottom surface of the fixed table 1. The first blind holes 10 and the second blind holes 3 are provided with internal threads, and the mounting plate 2 is provided with two, A first through hole 6 is provided on the corresponding positions of the board surfaces of the two mounting plates 2, and a first boss is integrally connected to the top of the mounting plate 2, and a second through hole 4 is arranged in the first boss, and the second through hole 4 is provided in the first boss. Two through holes 4 are provided with internal threads, the diameter of the second ...

Embodiment 2

[0026] As an optimization of the above embodiment, the bottom of the mounting plate 2 is integrally connected with a second boss, and a third through hole 12 is provided in the second boss. When the fixed object is wide, it cannot pass through the first through hole. 6 and fixing screw 7 when installing the mounting plate 2 on the fixed object, the mounting plate 2 can also be installed on the surface of the fixed object through the second boss and the third through hole 12; the second blind holes 3 are arranged in pairs At the middle position of the bottom of the fixed table 1, there are two second through holes 4 corresponding thereto at equal intervals. When it is used, the mounting plate 2 can be more firmly fixed on the bottom of the fixed table 1 through the two second through holes 4 , to prevent it from rotating; the top of the fixed table 1 is provided with a soft rubber layer 11, which can form a buffer between the combiner and the fixed table 1 during application to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com