Flexible protective garment

A flexible protection and elastic support technology, applied in protective clothing, special outerwear, convertible clothing, etc., can solve the problems of lack of flexibility and soft performance of fabrics, etc., to meet the needs of comfort, high use value, and wide-ranging The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementations provided according to the present invention will be described in detail below in conjunction with the examples.

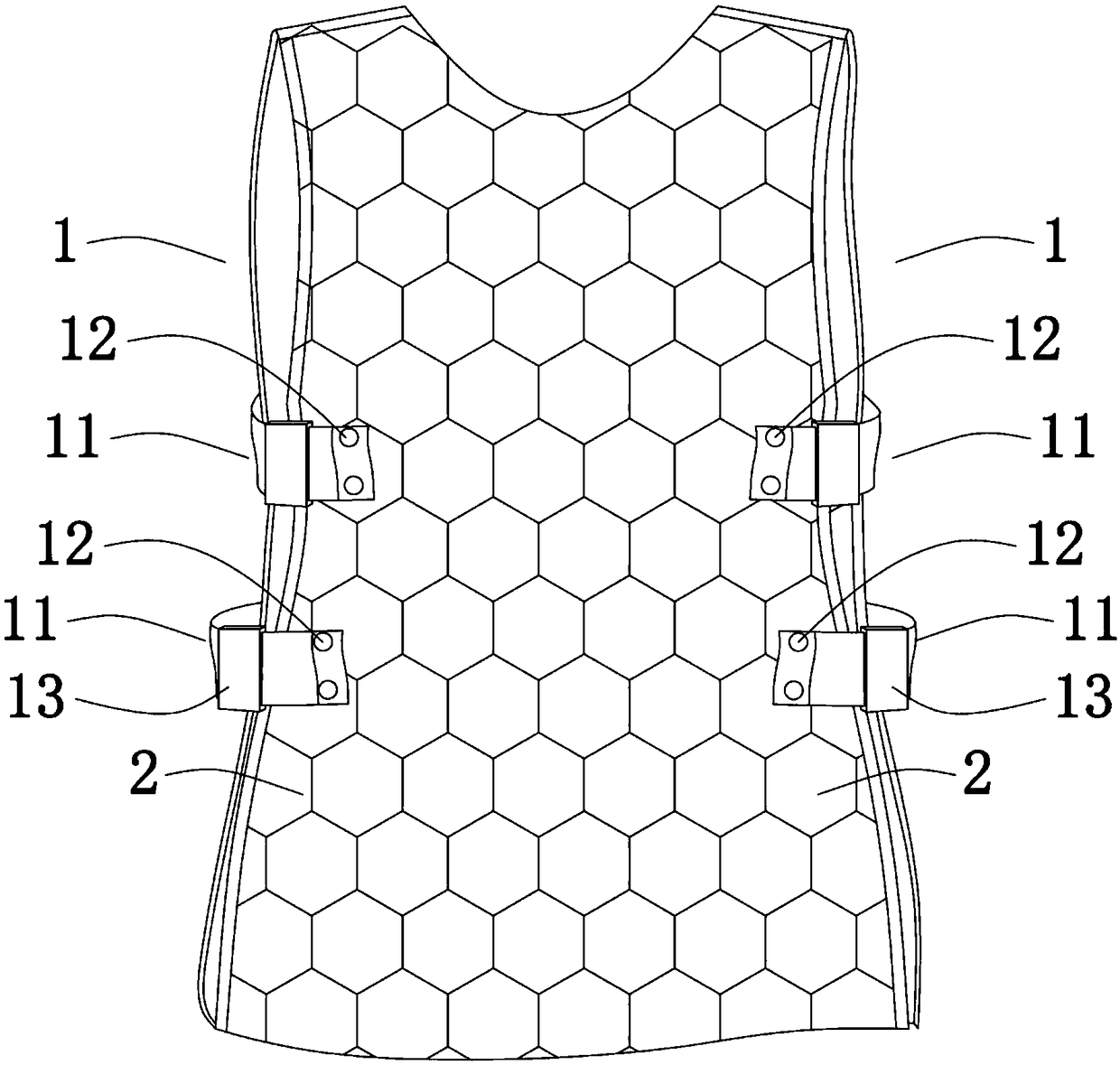

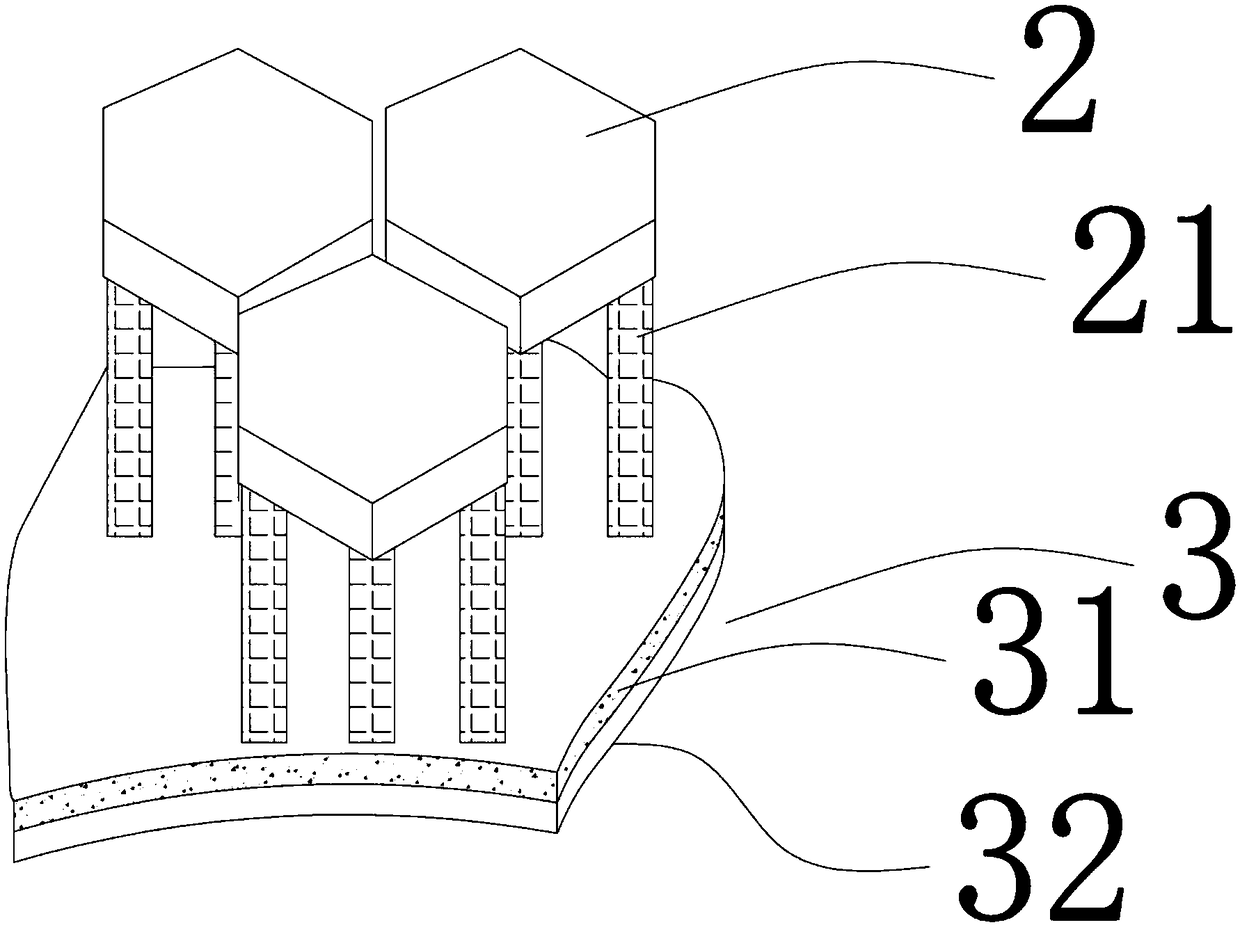

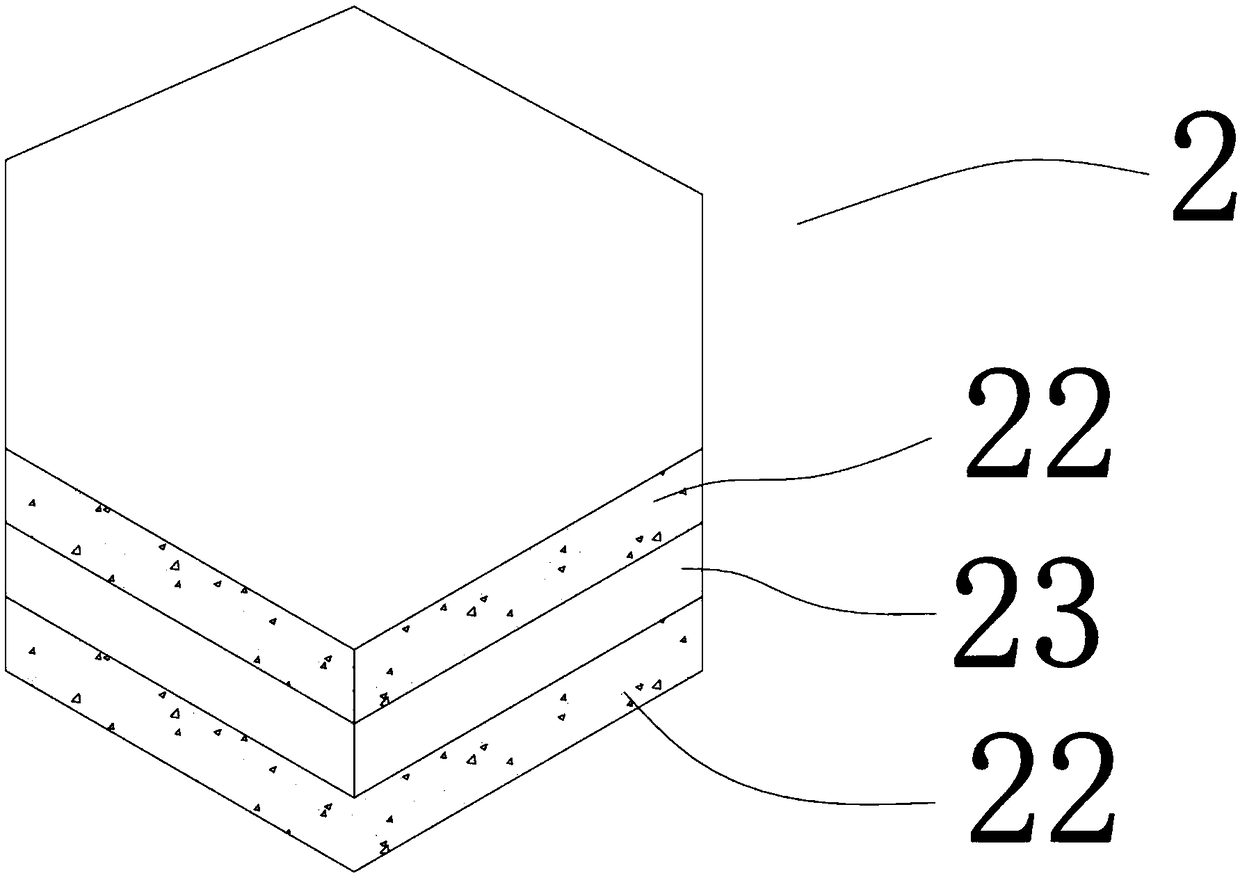

[0022] Such as Figure 1~3 As shown, it is a kind of flexible protective clothing of the present invention, which includes a flexible protective clothing body 1 in contact with the human body. The outer layer is provided with a connecting layer 3, and the connecting layer 3 sequentially includes a support layer 32 attached to the surface of the flexible protective clothing body 1 from the inside to the outside. The support layer 32 is provided with an elastic layer 31, and the elastic layer 31 is connected to the elastic support column 21. , the connection layer 3 is evenly provided with a plurality of flexible protective blocks 2, the bottom of the flexible protective block 2 is provided with a plurality of elastic support columns 21, one end of the elastic support columns 21 is connected to the flexible protective block 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com