A kind of whole plant ginseng puree processing method and application

A processing method and technology of ginseng, applied in the field of medicine, can solve the problems of high production cost, long processing time, complicated operation process, etc., and achieve the effect of quick onset, advanced processing method and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

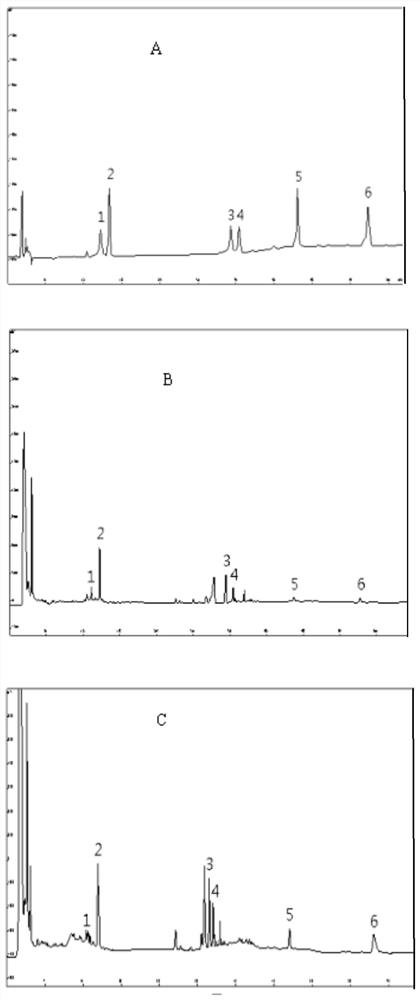

[0043] Example 1: Preparation of whole ginseng puree

[0044] Take 350g of fresh ginseng to clean fresh ginseng by ultrasonic oscillation for 18min, the ultrasonic frequency is 40KHz, and its power density is 1.0W / cm 2 Within the range; take 70g of yam, cut the cleaned yam into sections, put it into a high-speed beater, add 3 times of water, heat and beat, the beater power is 850W, the speed is 26000r / min, and the heating and beating time is 6min. Then homogenize and emulsification, the rotating speed is 2800r / min, and the homogenization time is 8min. The particle size of the slurry is 20-80 μm; the contents of rare saponins are: Rg 3 0.022mg / g, Rh 2 0.033mg / g, Rh 1 It is 0.065mg / g.

[0045] The processed puree product was bottled, and sterilized for 2 minutes routinely to obtain whole fresh ginseng puree.

Embodiment 2

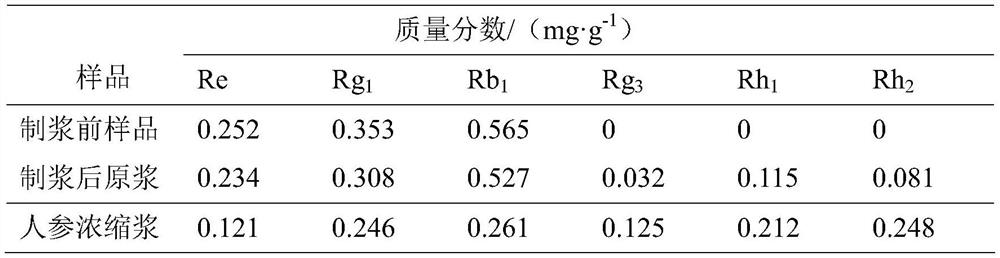

[0046] Example 2: Preparation of whole plant ginseng puree

[0047] Take 350g of fresh ginseng to clean fresh ginseng by ultrasonic oscillation for 20min, the ultrasonic frequency is 45KHz, and its power density is 1.2W / cm 2 Within the range; take 70g of yam, cut the cleaned yam into sections, put it into a high-speed beater, add 4 times of water, heat and beat, the beater power is 1000W, the speed is 30000r / min, and the heating and beating time is 10min. Then homogenize and emulsification, the rotation speed is 3000r / min, and the homogenization time is 12min. The particle size of the slurry is 15-60 μm; the contents of rare saponins are: Rg 3 0.032mg / g, Rh 2 0.081mg / g, Rh 1 It is 0.115mg / g.

[0048] The processed puree product was bottled, and sterilized for 2 minutes routinely to obtain whole fresh ginseng puree.

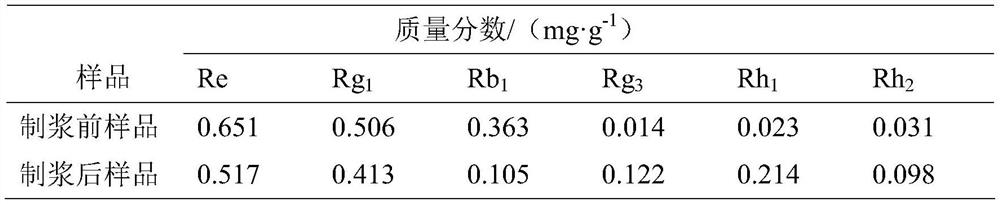

[0049] The comparison of the preparation results of Examples 1 and 2 shows that the content of rare saponins increases with the change of pulping parameters,...

Embodiment 3

[0050] Example 3: Preparation of whole plant dried ginseng puree

[0051] Take 100g of dry ginseng and pulverize it into fine powder (50-100 mesh); take 10g of yam and cut it into sections, put the pulverized dry ginseng powder and yam section into a high-speed beater, add 1.5 times water, heat and beat, and the beating power is 850W, the rotating speed is 26000r / min, and the heating and beating time is 6min. Then homogenize and emulsification, the rotating speed is 2800r / min, and the homogenization time is 8min. The particle size of the slurry is 15-60 μm; the contents of rare saponins are: Rg 3 0.027mg / g, Rh 2 0.041mg / g, Rh 1 is 0.072 mg / g.

[0052] The processed puree product is bottled, and sterilized for 2 minutes in a routine manner to obtain the puree of the whole ginseng.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com