Paint spraying device capable of improving spraying quality

A technology of spraying device and paint, which is applied in the directions of spraying device, spraying device, spraying room, etc., can solve the problems such as the inability to guarantee the distance between the spray gun mouth and the surface, the high concentration of benzene, and the great harm to the spraying workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

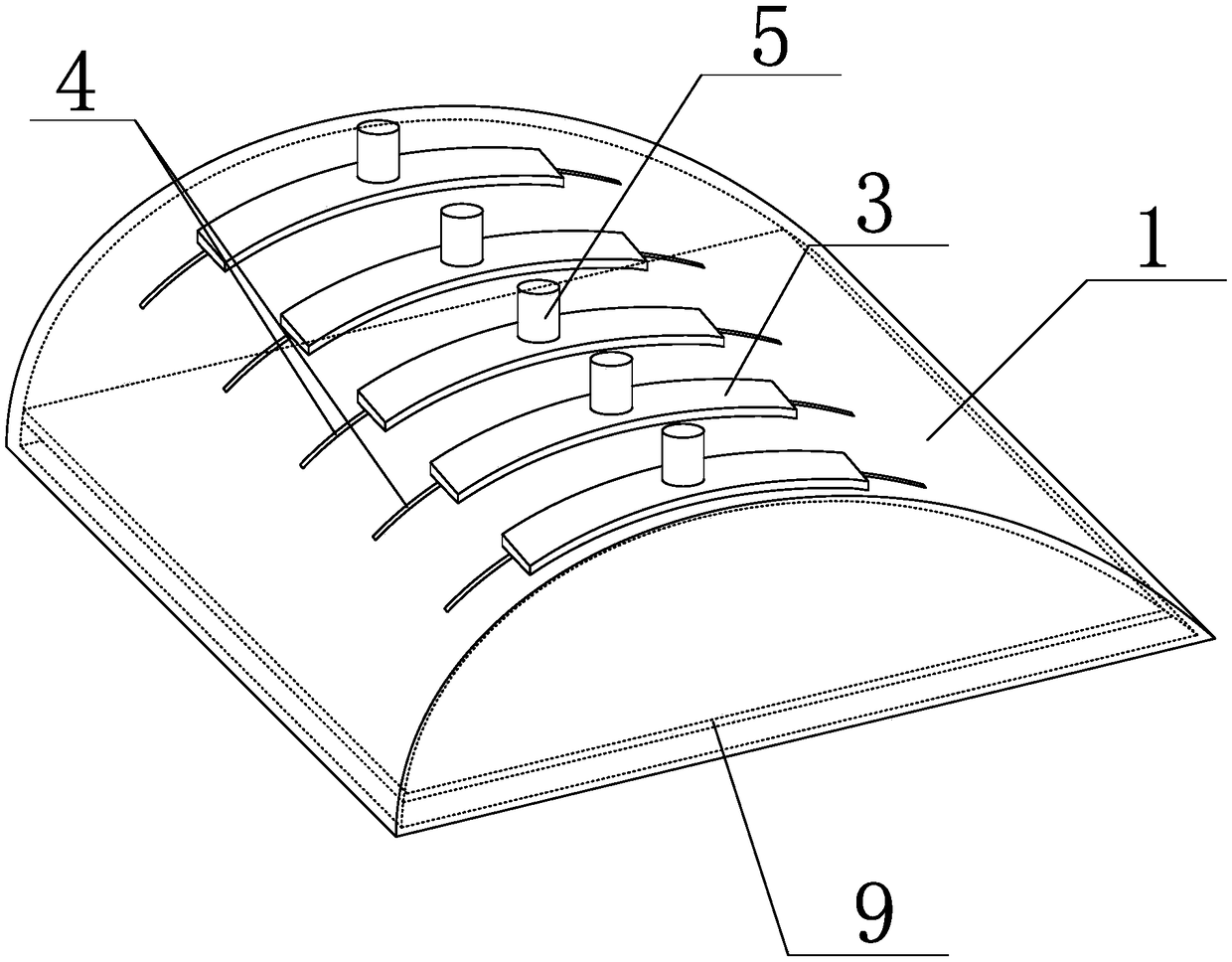

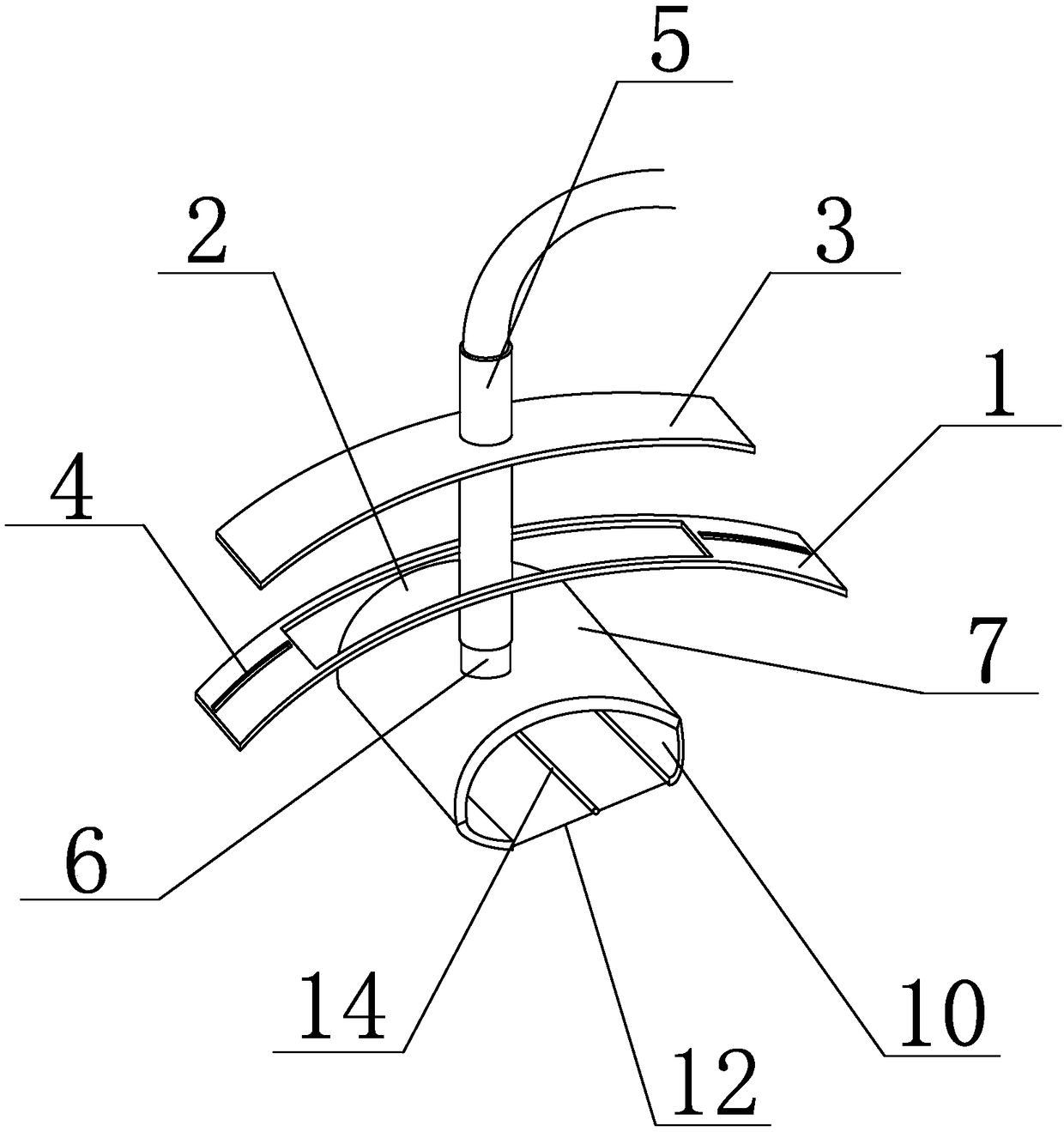

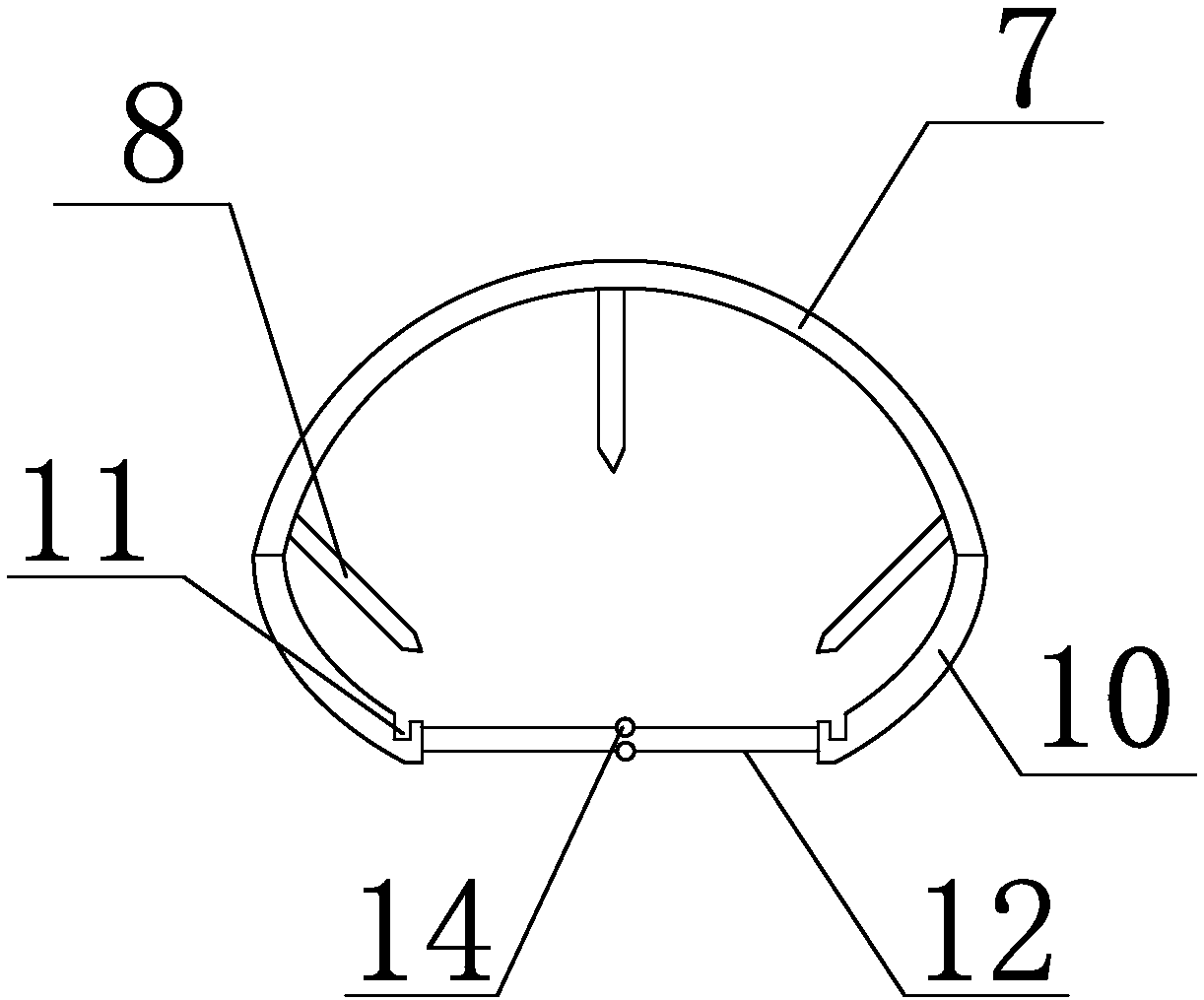

[0030] Such as figure 1 and figure 2 As shown, the paint spraying device for improving the spraying quality of the present invention includes a semi-cylindrical shield cover 1, the bottom surface of the shield cover 1 is open, and the arc-shaped top plate of the shield cover 1 is provided with a plurality of strip-shaped slots along the axial direction. 2. Strip-shaped slots 2 are arranged along the circumferential direction of the shielding cover 1. Above each strip-shaped slot 2, there is a moving plate 3 in parallel with the outer wall of the top plate. Both ends of the strip-shaped slots 2 are respectively provided with Along the chute 4 provided in the circumferential direction of the top plate, sliders are provided at both ends of the lower surface of the moving plate 3, the sliders are clamped in the chute 4 and slidably connected with the bottom surface of the chute 4, and the moving plate 3 can move along the top plate. The circumferential direction moves back and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com