Patents

Literature

30results about How to "Diffusion will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon oil printing process for circuit board

InactiveCN103874336ABeautiful appearanceReduce scrapConductive pattern formationScreen printingEngineering

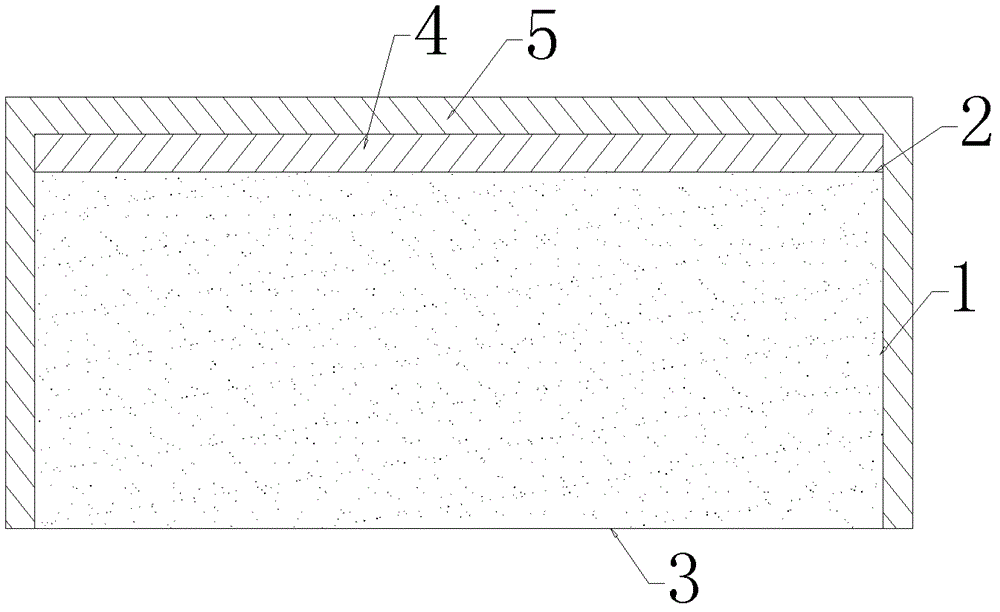

The invention discloses a carbon oil printing process for a circuit board. The process comprises the following steps of 1, cleaning the board surface of the circuit board; 2, pasting a water film; 3, coating photosensitive glue; 4, exposing; 5, developing; 6, drying. The board surface of the circuit board is coated with a layer of water film with the thickness of 35 [mu]m, and the photosensitive glue is coated on the obverse side and the reverse side before a screen printing plate is exposed, so that the screen printing plate is more uniform and neater, and in addition, the thickness of the screen printing plate is increased, so that the screen printing plate is more stable in shape during printing and is not easy to deform, and the reliability is improved; the printing thickness of carbon oil is increased, so that the problems of short circuit and open circuit at places with high use frequency can be effectively prevented; the thickness of the water film is adjusted from the original 25 [mu]m to 35 [mu]m, and the thickness of the film is increased, so that carbon oil is prevented from being diffused and leaked, the manufacturing yield of the carbon oil is effectively improved, the quality of a PCB (printed circuit board) is improved, the appearance of the board surface is more attractive, scrap of circuit boards is reduced, and the manufacturing cost of the carbon oil is reduced.

Owner:奥士康精密电路(惠州)有限公司

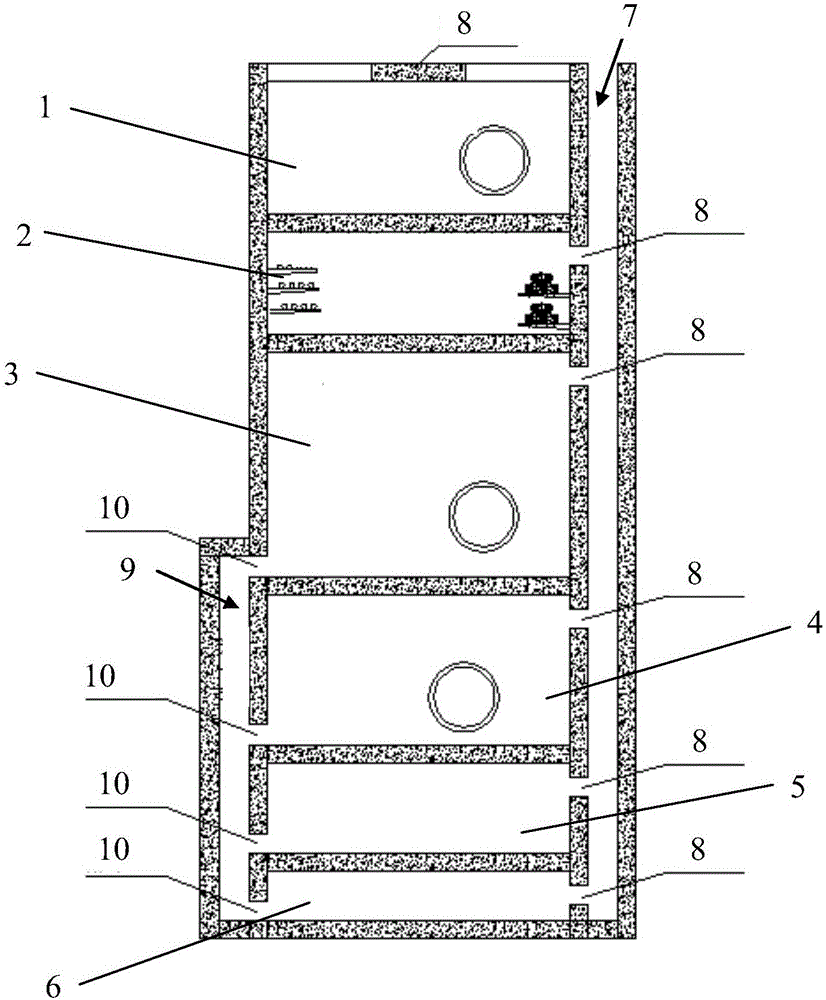

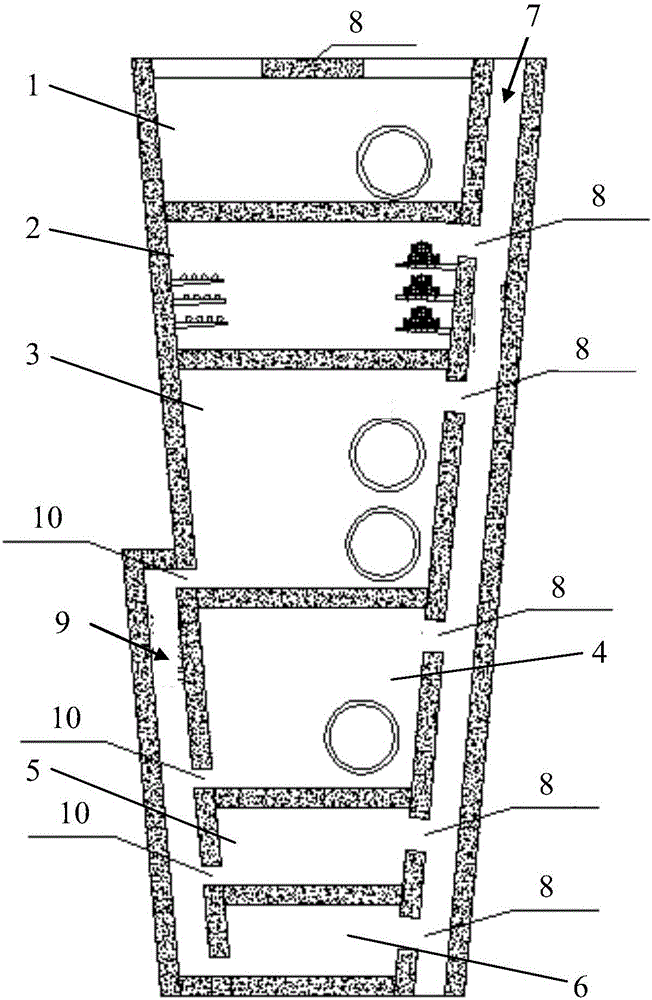

Multilayer urban underground comprehensive pipe gallery

InactiveCN106351254AEffective separationReduce the risk of security incidentsArtificial islandsUnderwater structuresUtility tunnelSystem structure

The invention discloses a multi-layer urban underground comprehensive pipe gallery, which comprises: a dangerous gas structure layer arranged on the top floor of the comprehensive pipe gallery for carrying natural gas pipelines; a power and telecommunication system structure layer arranged under the dangerous gas structure layer , used to carry power and communication equipment and cable devices; and the sewage structure layer, which is set at the bottom of the comprehensive pipe gallery, and used for sewage drainage in the comprehensive pipe gallery; among them, the dangerous gas structure layer, the power telecommunication system structure layer and the sewage discharge structure layer They are isolated from each other to form independent compartments with functional partitions. The multi-layer urban underground comprehensive pipe gallery of the present invention significantly improves the comprehensive utilization efficiency of urban land, improves the safety of the design of the pipe gallery, reduces the construction cost of the urban comprehensive pipe gallery, and has positive effects on the construction of the urban comprehensive pipe gallery. Guiding significance.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

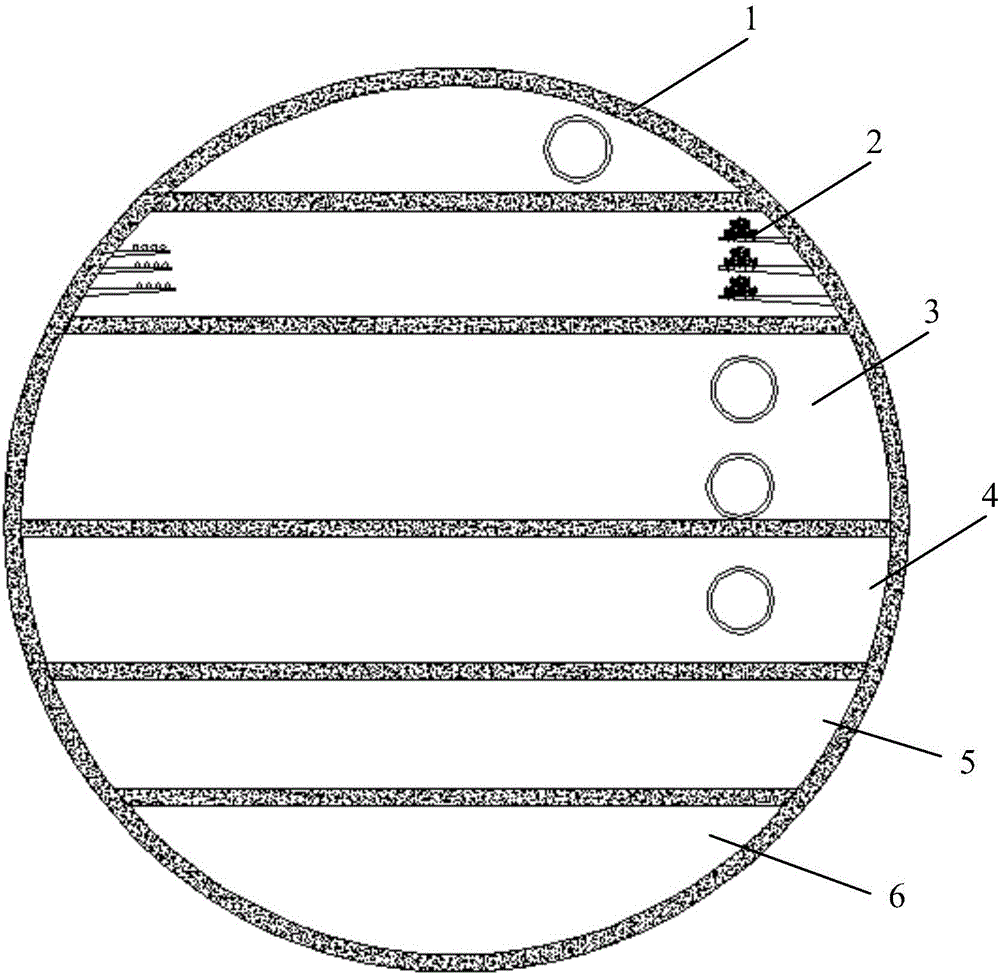

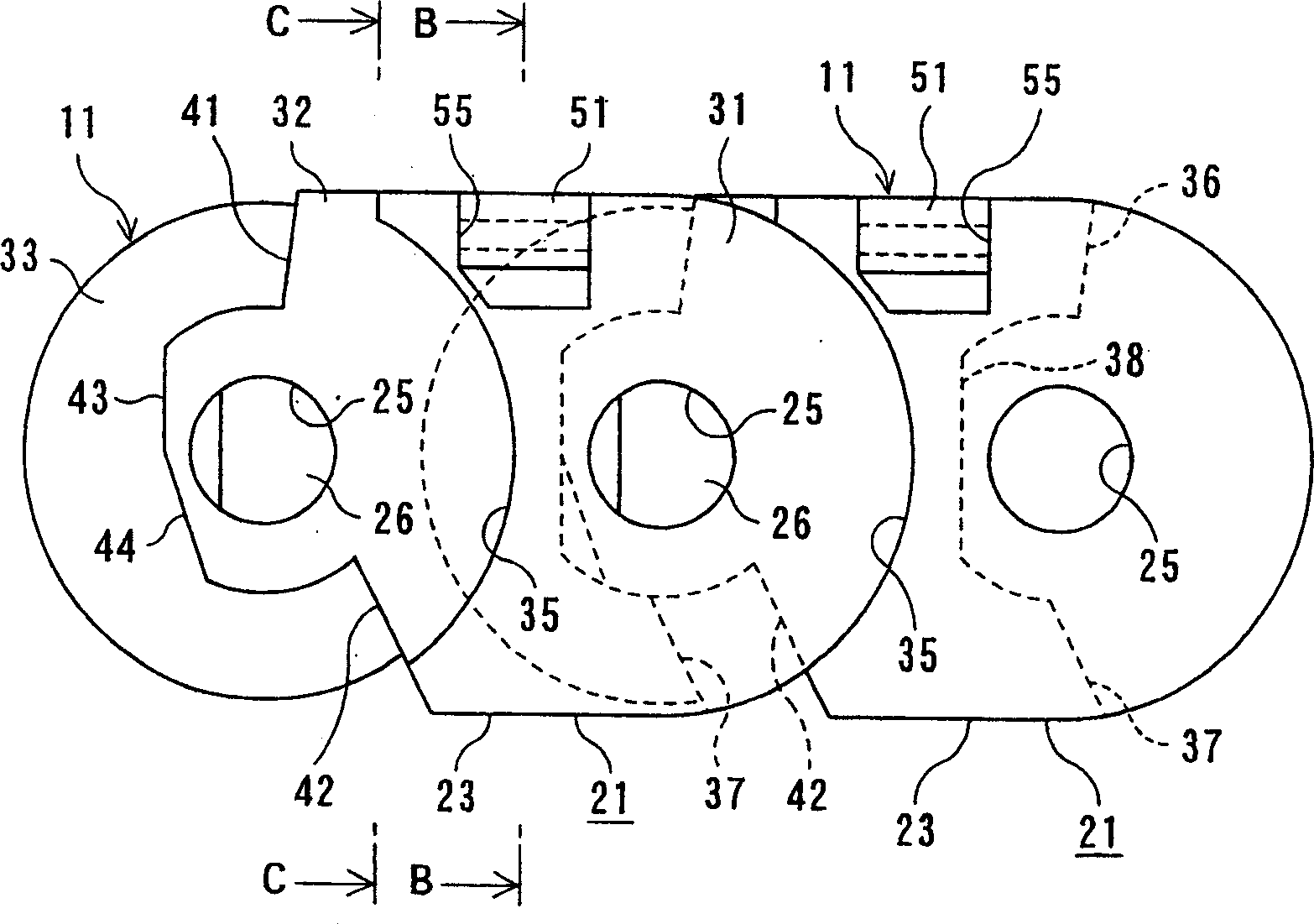

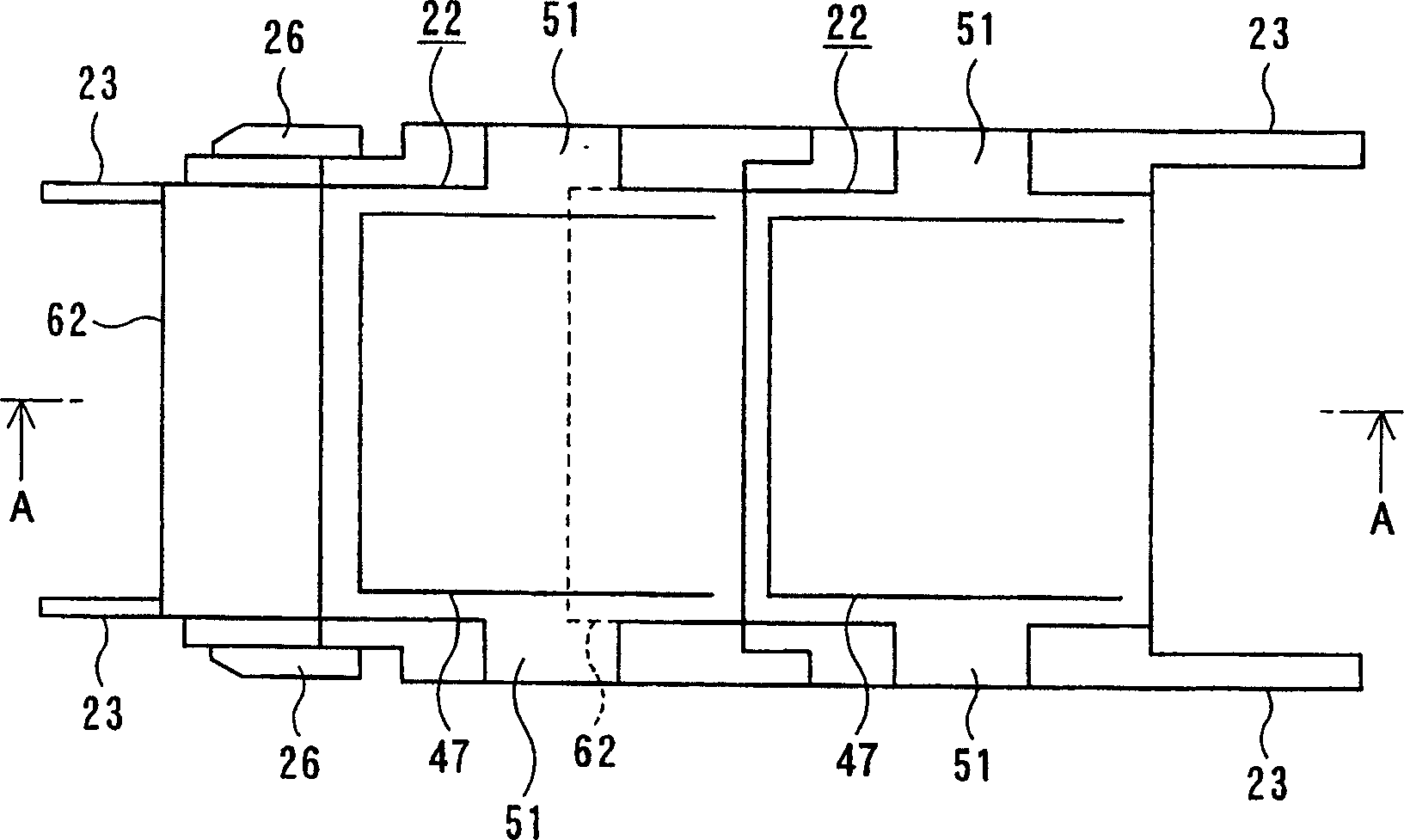

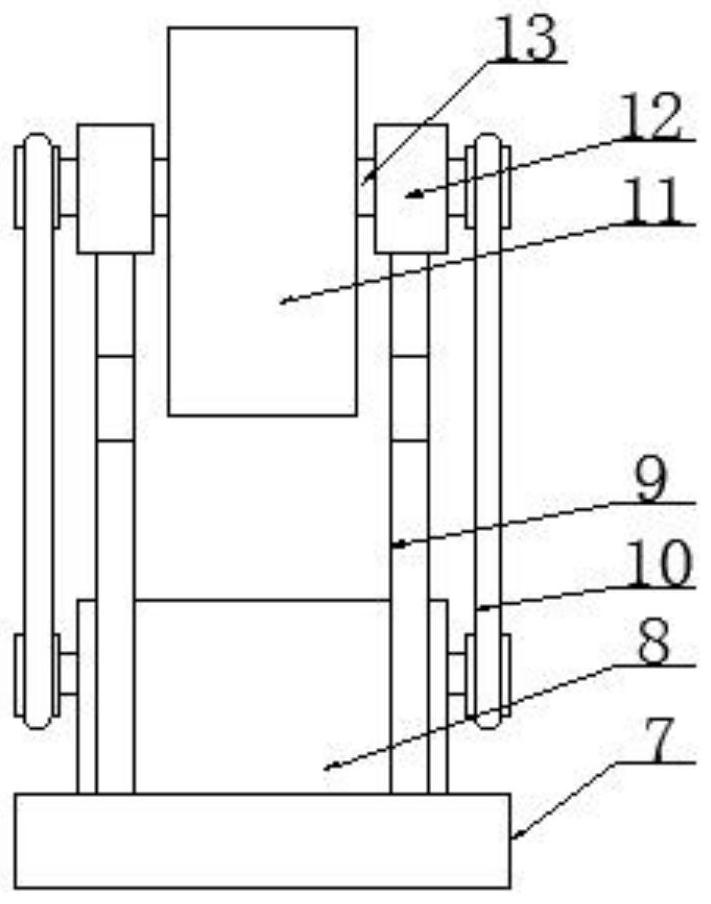

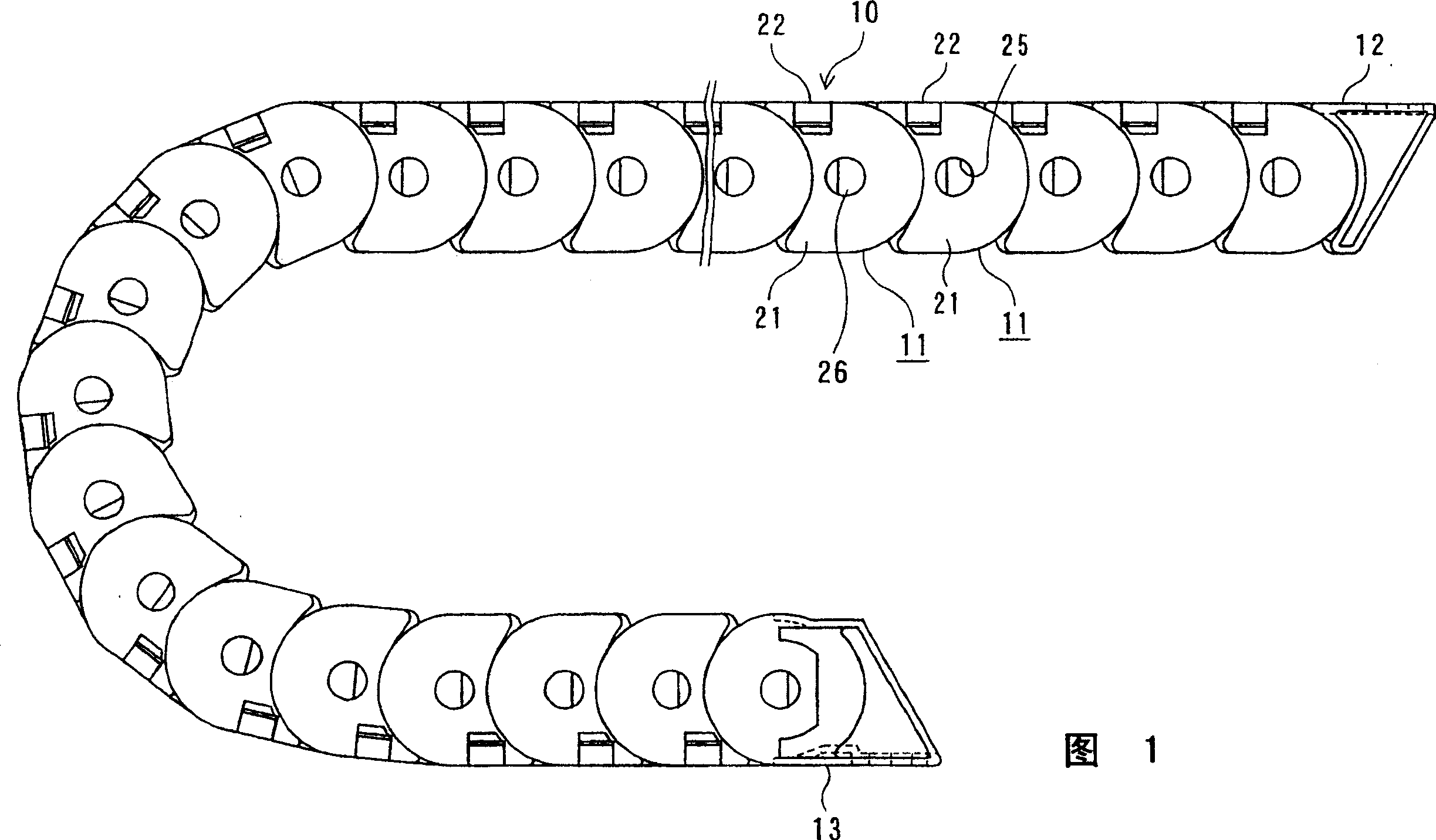

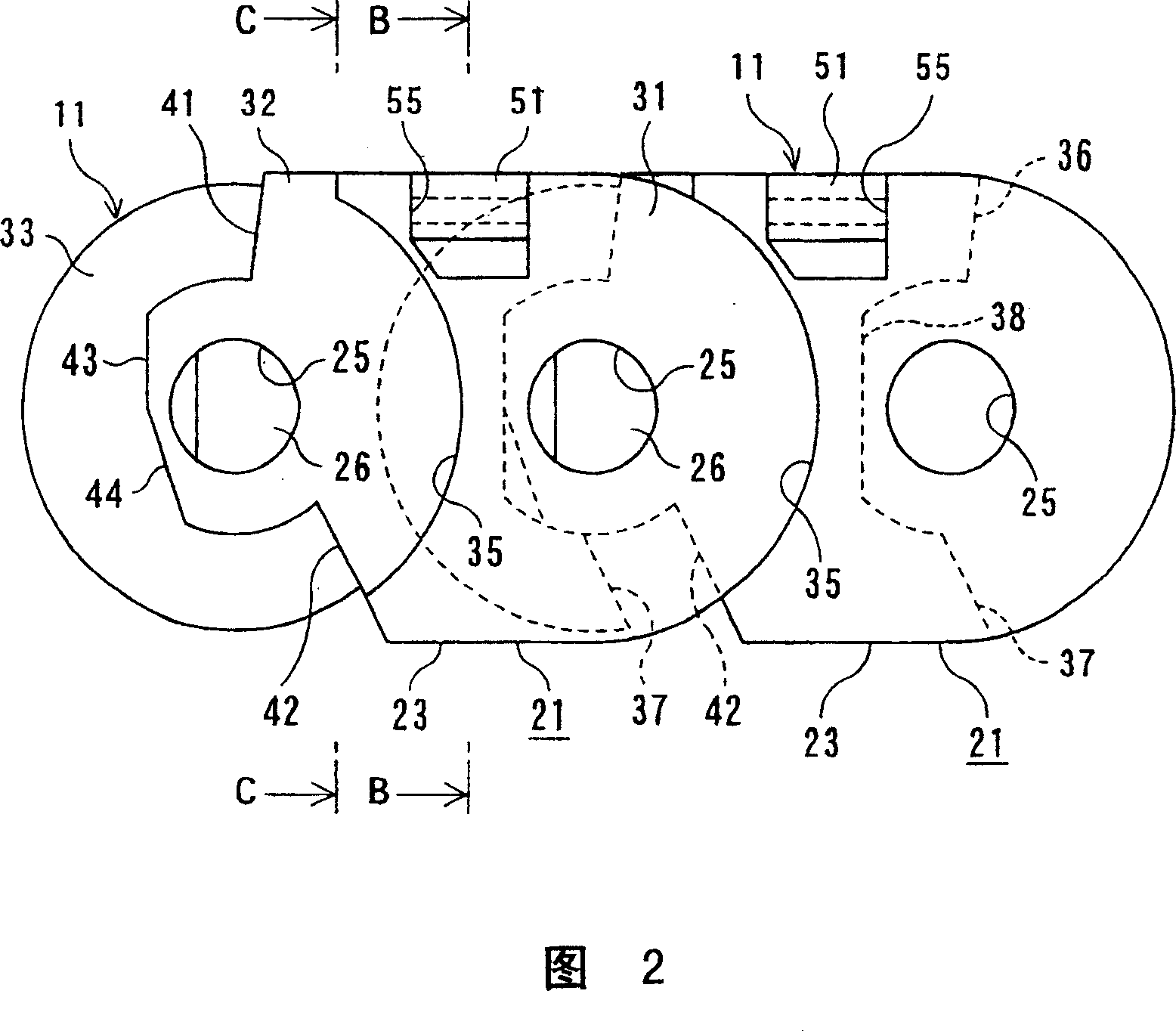

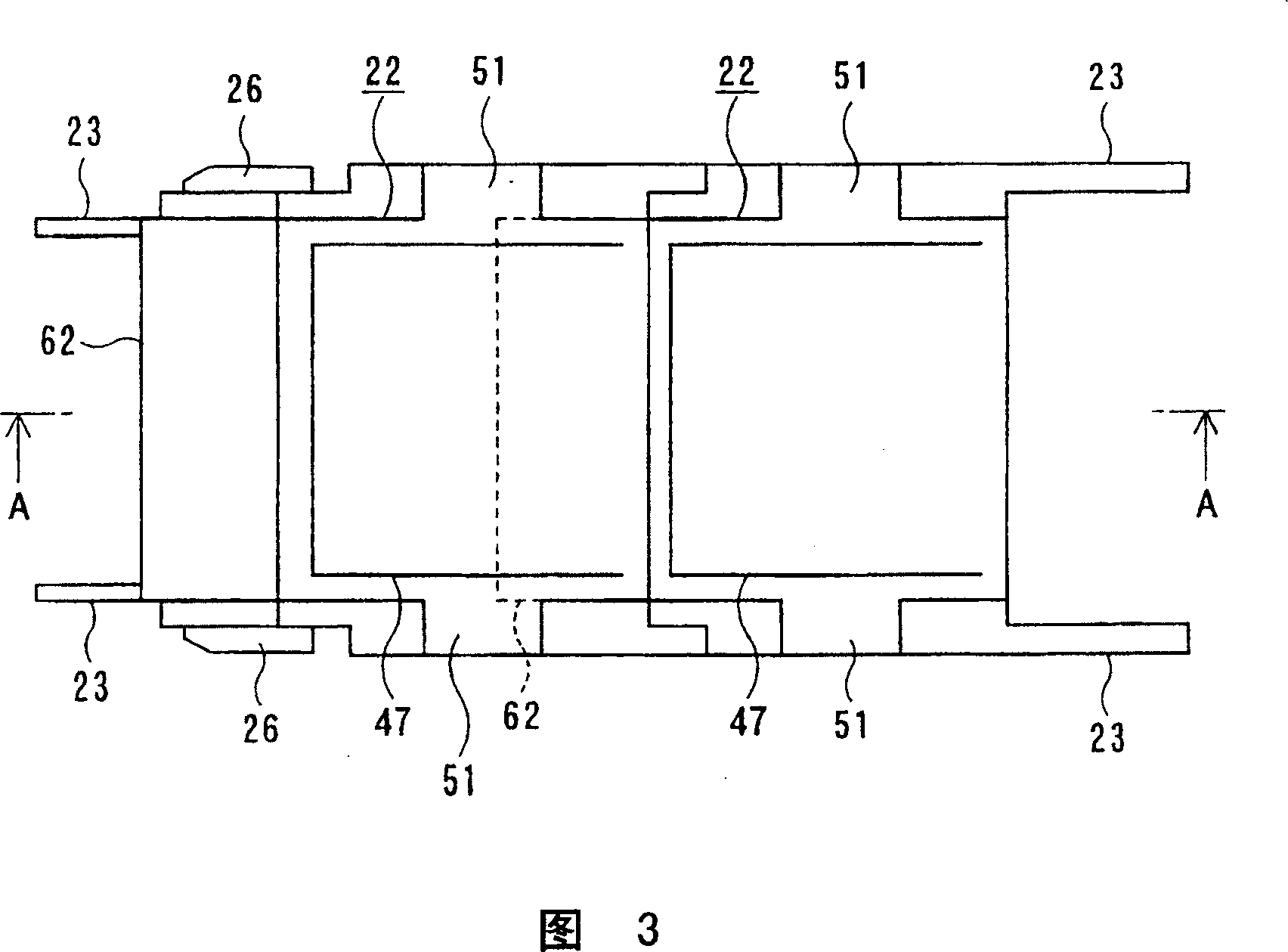

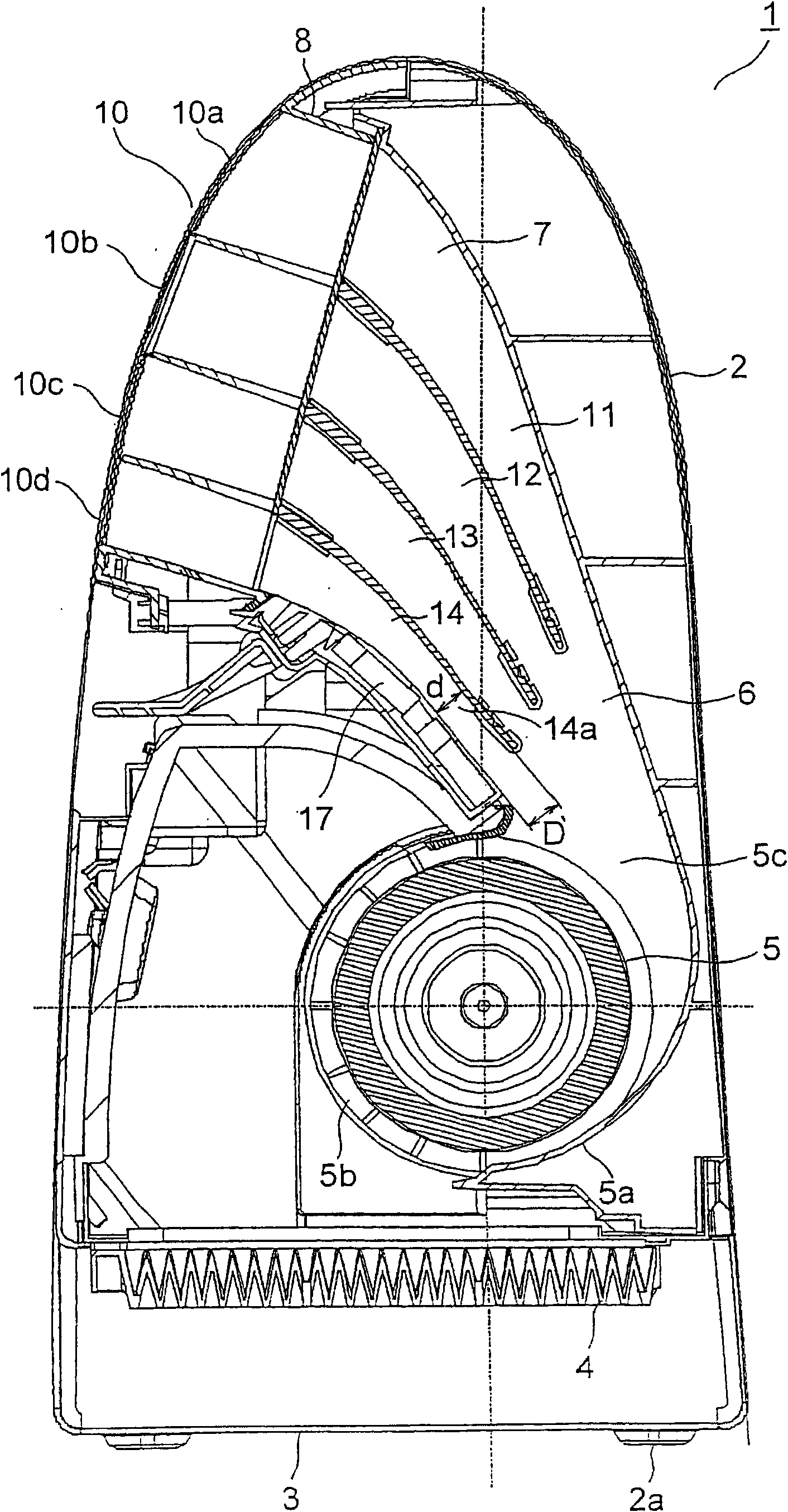

Cable or the like protection and guide device

To provide a cable or the like protection and guide device that does not disperse dust particles such as wear particles generated by slide or friction between a cable or the like and link frame bodies. A number of link frame bodies ( 11 ) articulably connected to each other in the longitudinal direction of the device in a state where a cable or the like ( 14 ) are accommodated and hermetically sealed, each comprise a pair of link plate ( 23 ) disposed on both sides of the cable or the like, and connecting rods ( 22, 24 ) bridged across the link plates on the bend outer peripheral side and on the bend inner peripheral side, respectively. Between at least the bend outer peripheral side of the link plate and the connecting rod ( 24 ) bridged on the bend outer peripheral side is openably provided a sealing structure by concave and convex fitting ( 48, 49, 148, 149, 148, 149 ). Thus, the respective frame bodies are reliably hermetically sealed by the connecting rods ( 24 ) and dust particles present in the inside space of the link frame bodies through which the cable or the like is penetrated are not dispersed outside.

Owner:TSUBAKIMOTO CHAIN CO

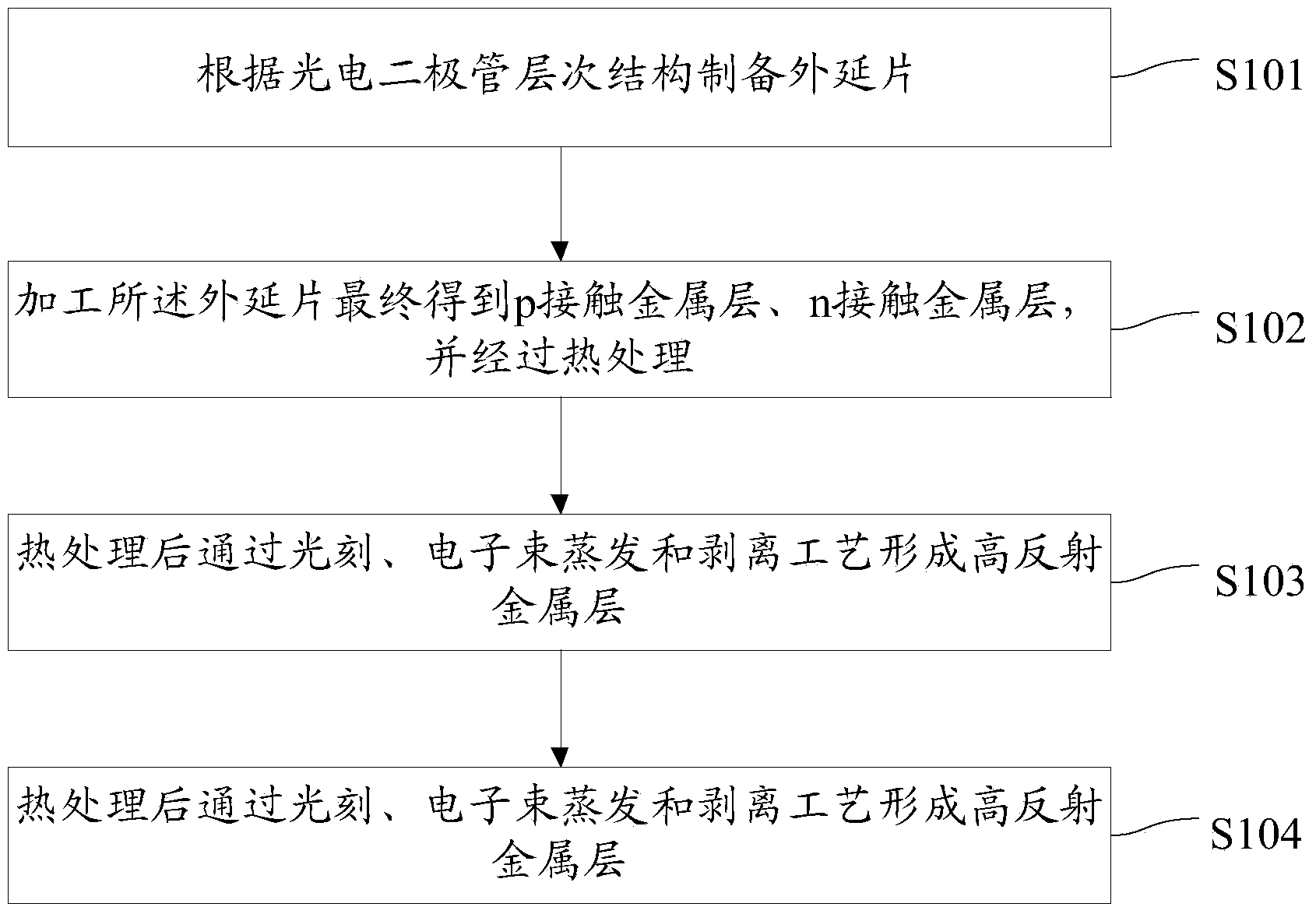

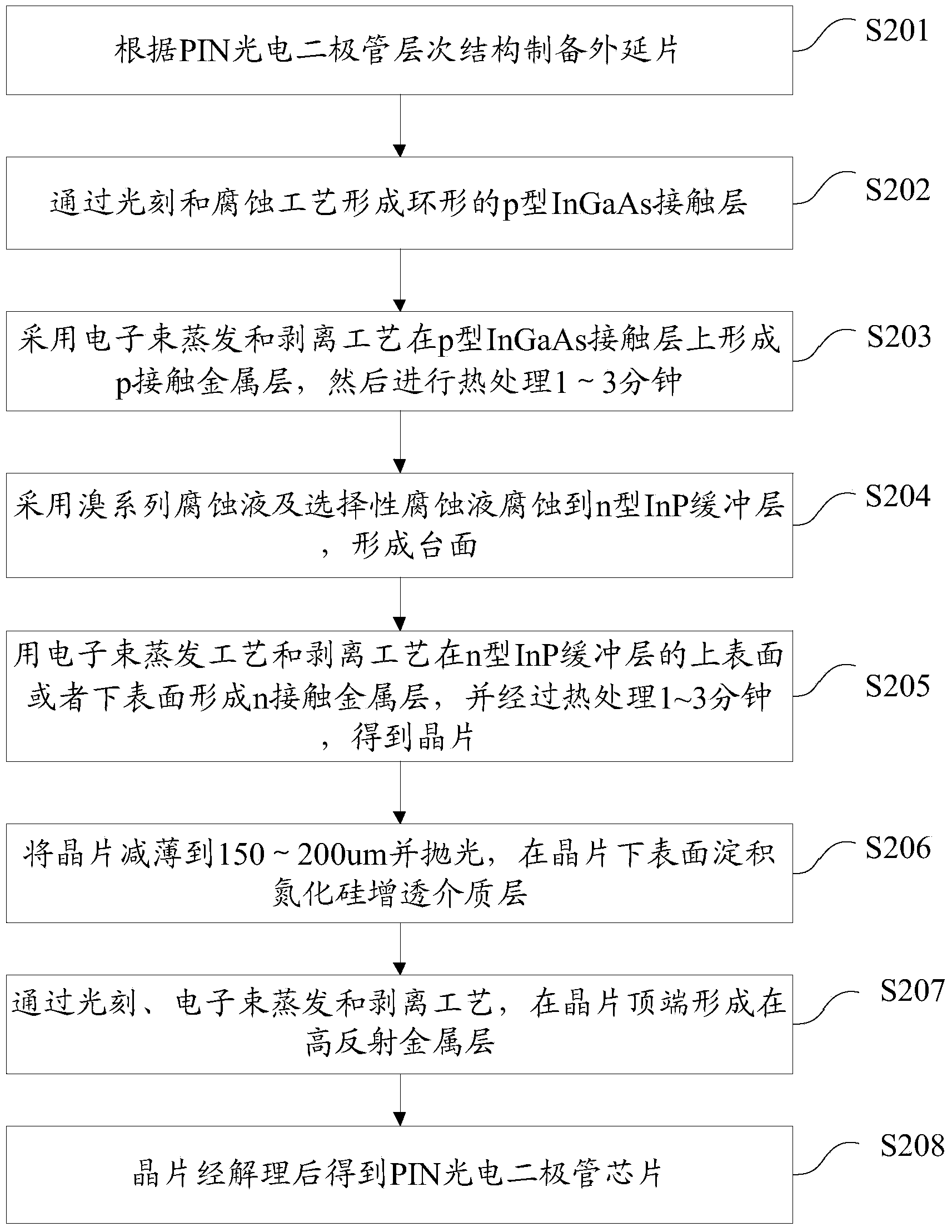

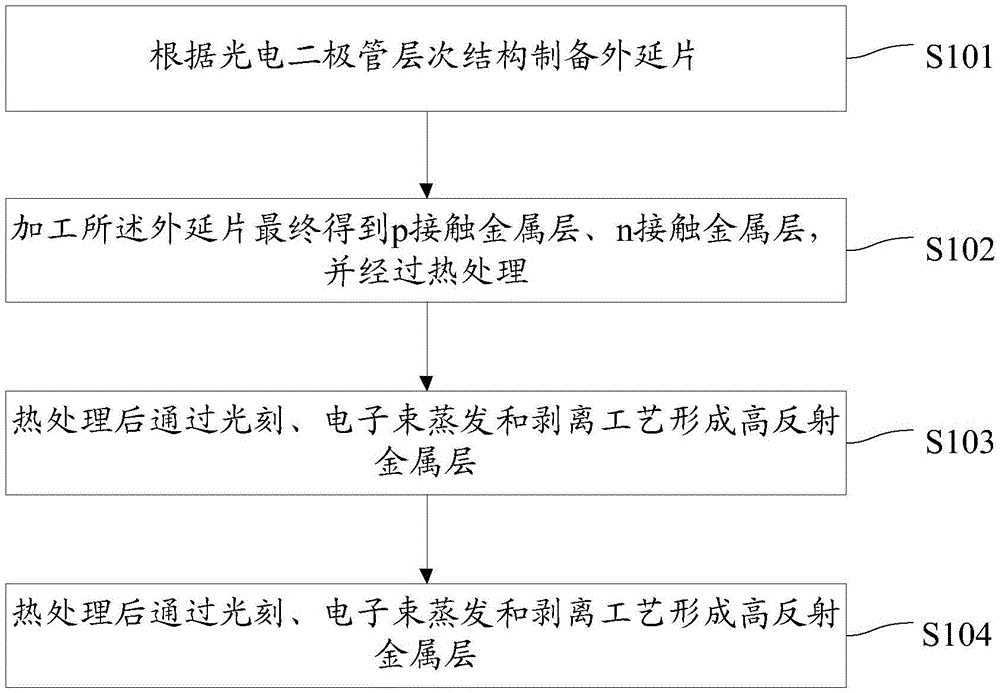

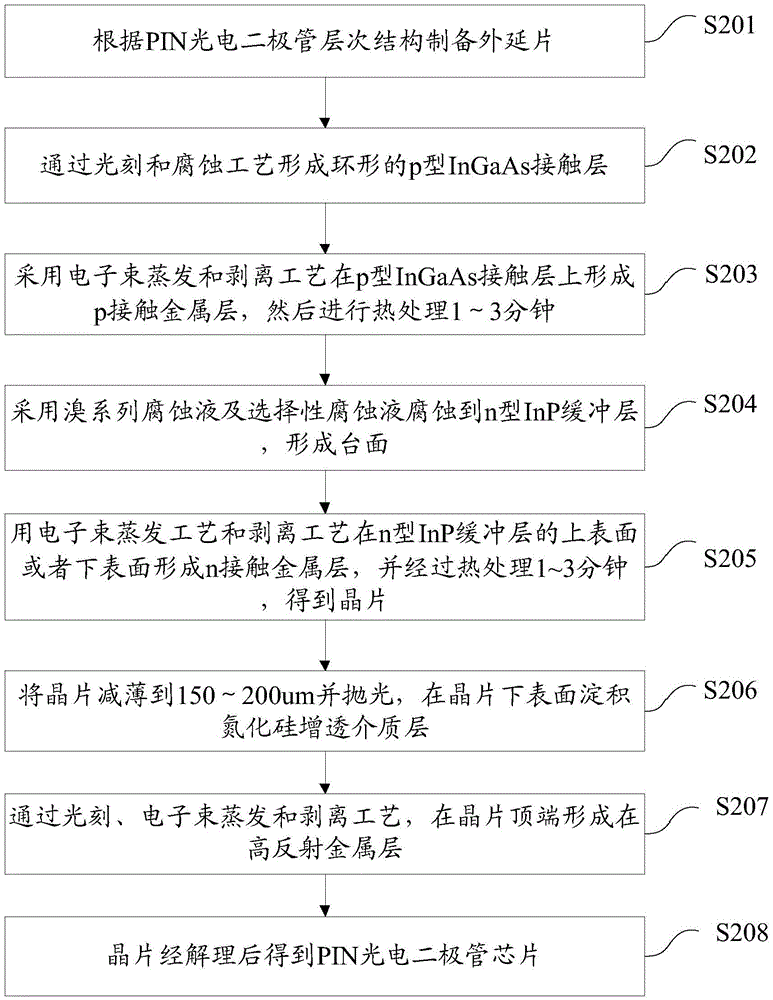

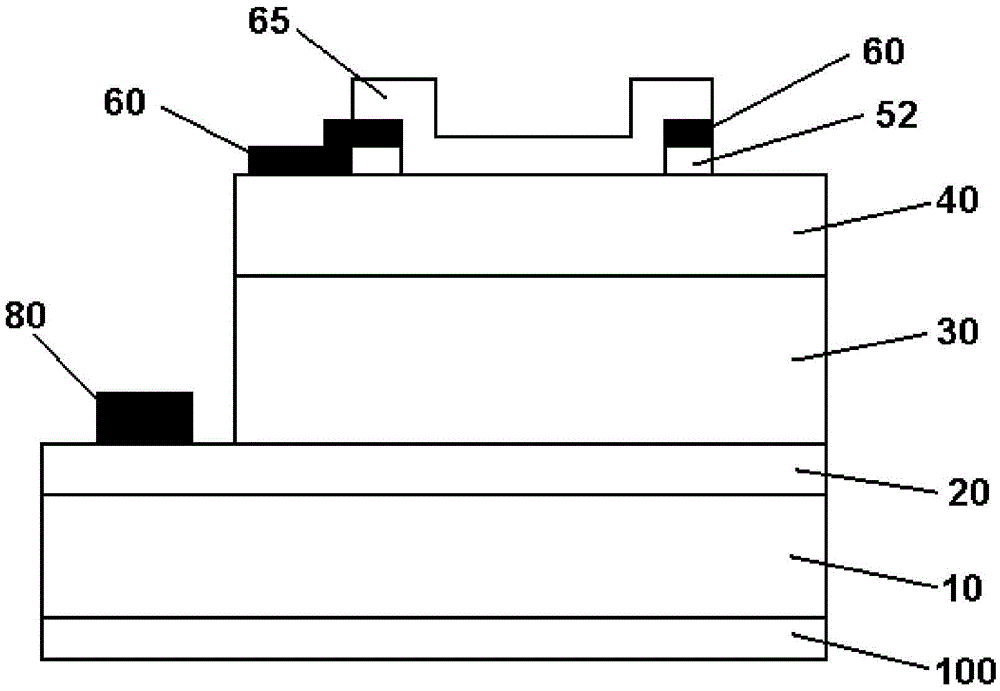

Manufacturing method of photo diodes

ActiveCN104022181AImprove responsivenessImprove reflectivitySemiconductor devicesEtchingThermal treatment

The invention is suitable for chip manufacturing field, and provides a manufacturing method of photo diodes, which comprises the following steps: preparing an epitaxial wafer according to photo diode architecture; machining the epitaxial wafer for finally obtaining a p contact metal layer, an n contact metal layer, and performing thermal treatment; after thermal treatment, forming a high-reflection metal layer through photo-etching, electronic beam evaporating and stripping processes; and obtaining a photo diode chip through cleavage. According to the technical solution of the manufacturing method, after the p contact metal layer and the n contact metal layer are all manufactured, and furthermore all thermal treatments are performed, a high-reflection metal layer is formed. The reflection rate of the high-reflection metal layer can be improved to above 75%, and responsibility of the photo diode is effectively improved.

Owner:WUHAN TELECOMM DEVICES

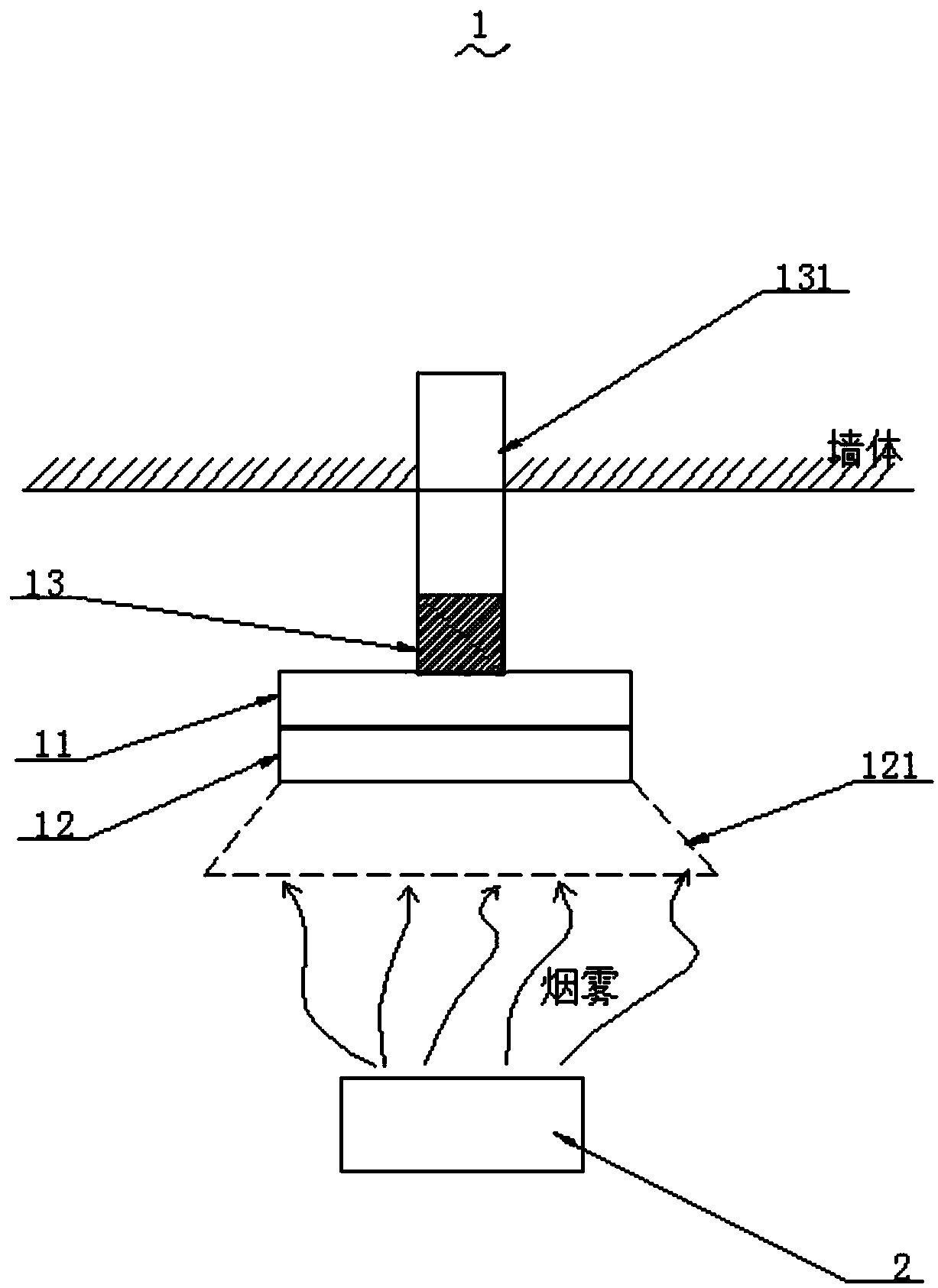

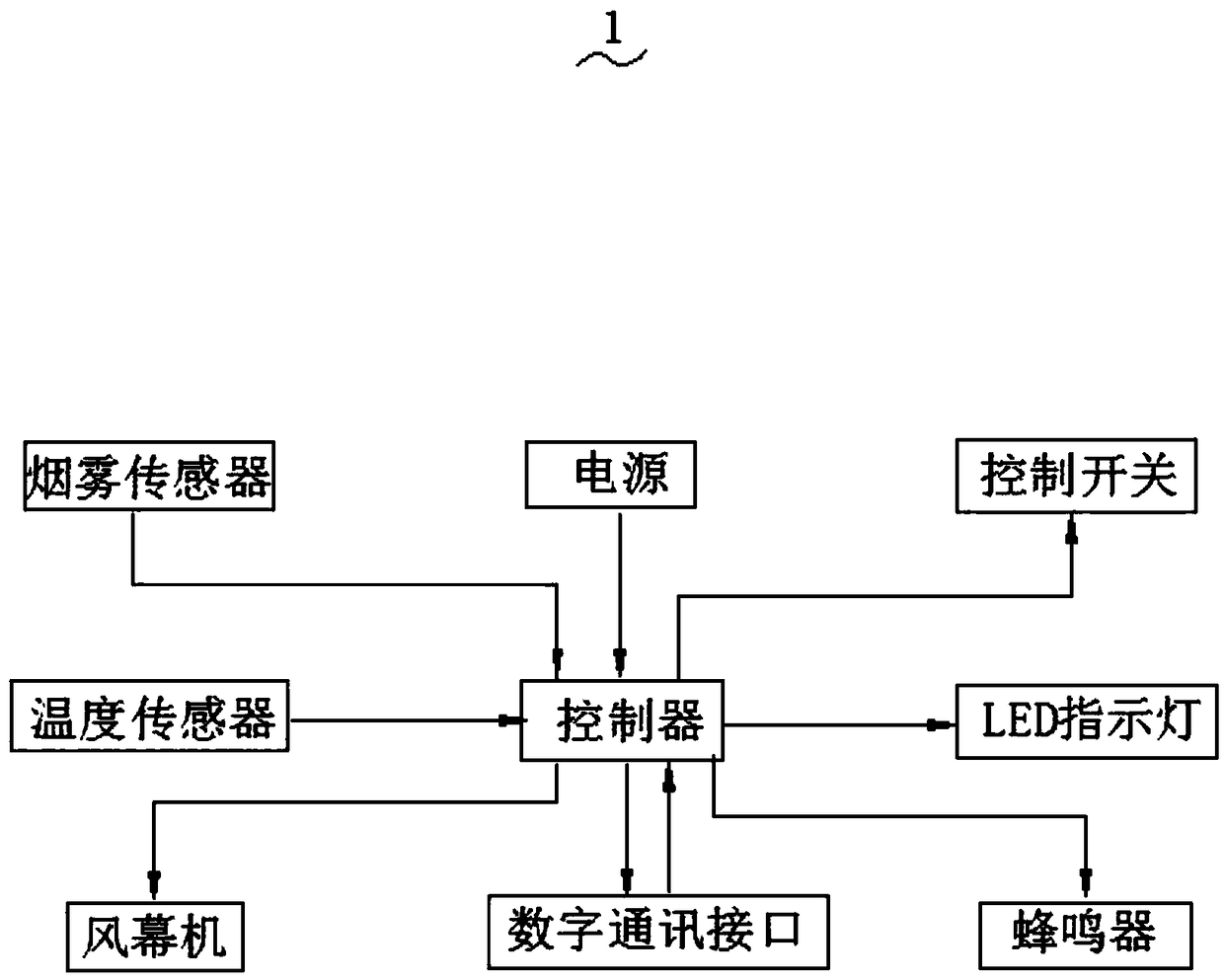

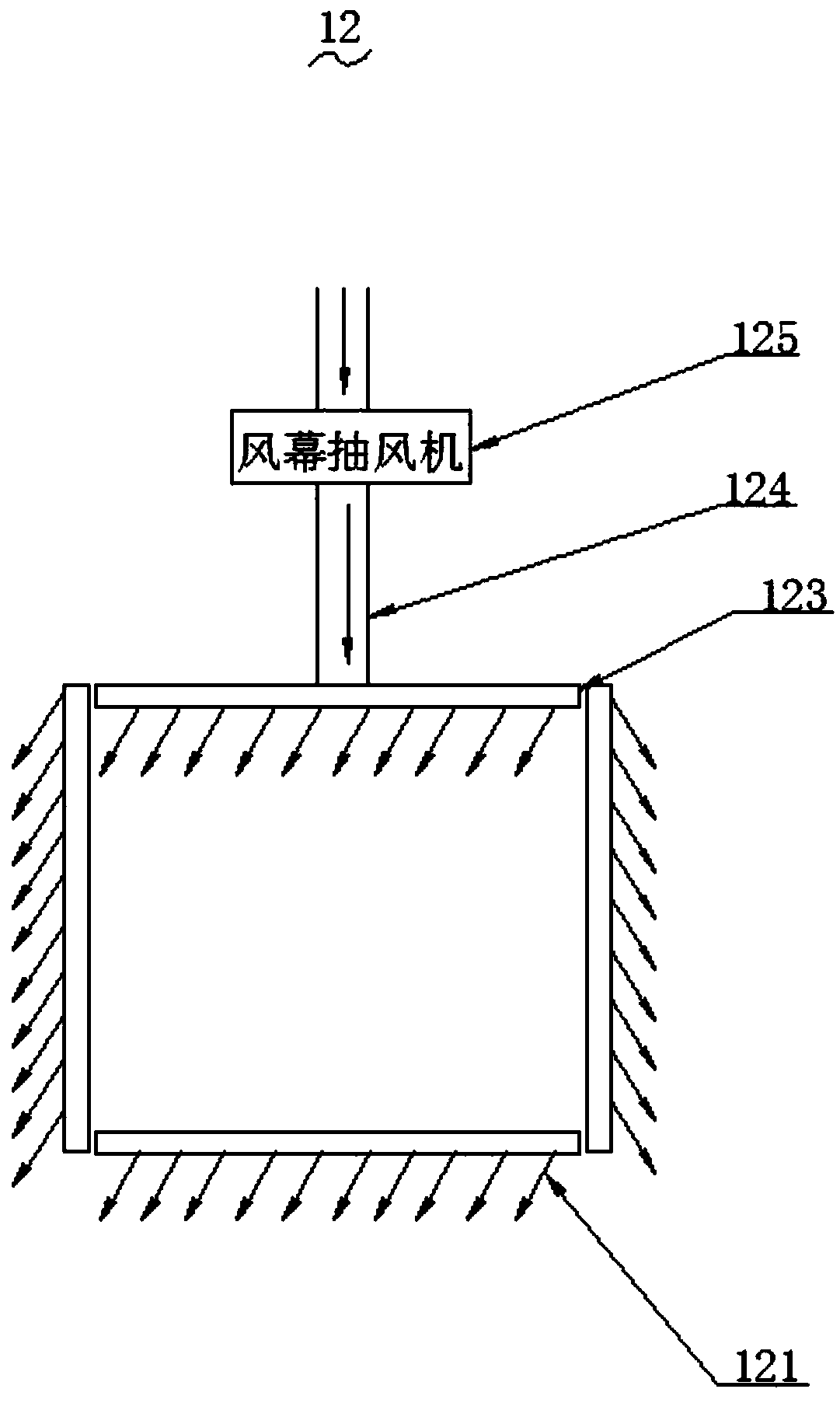

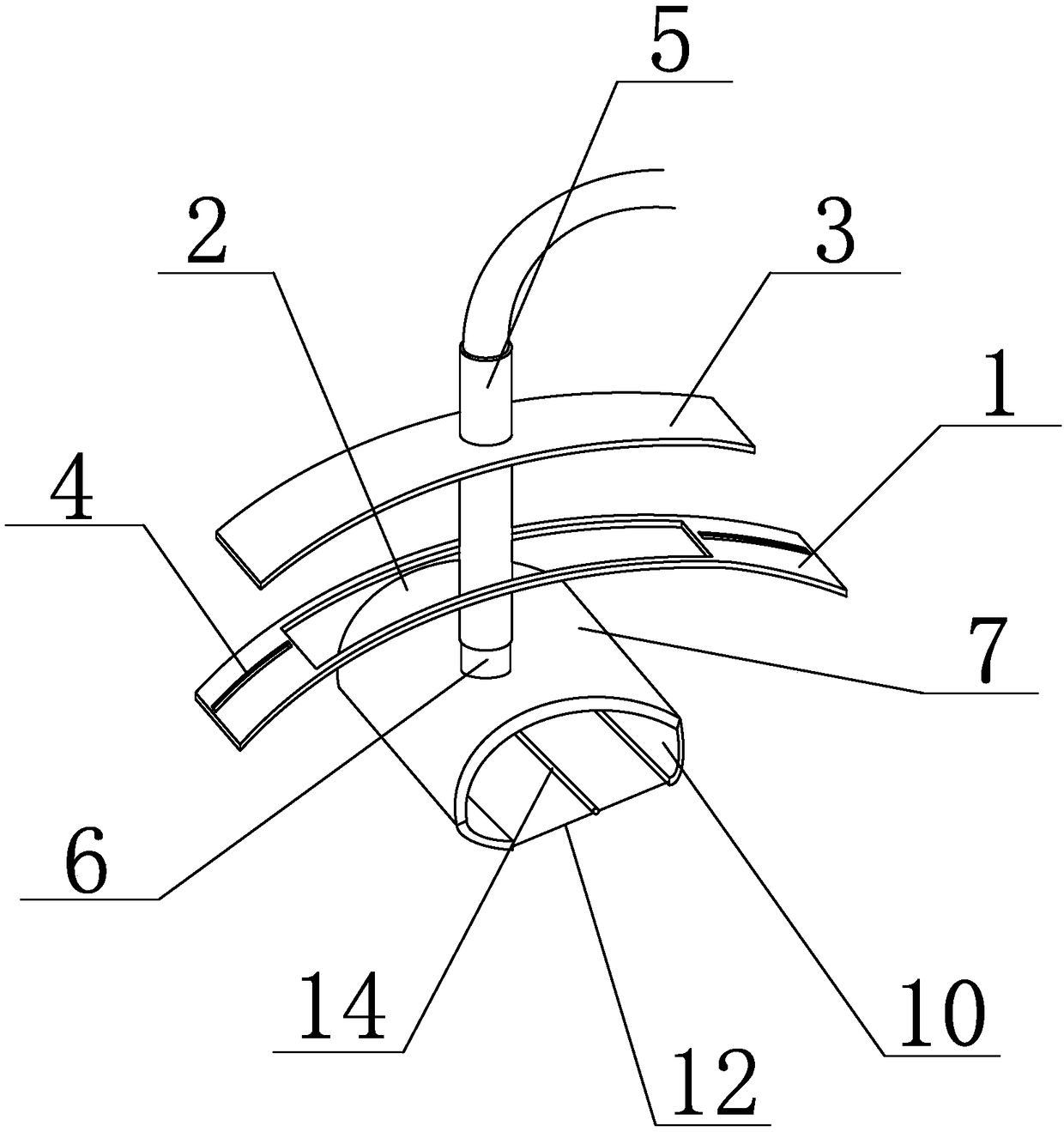

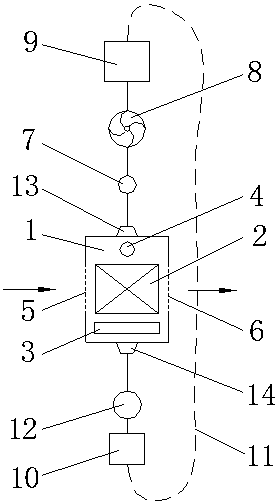

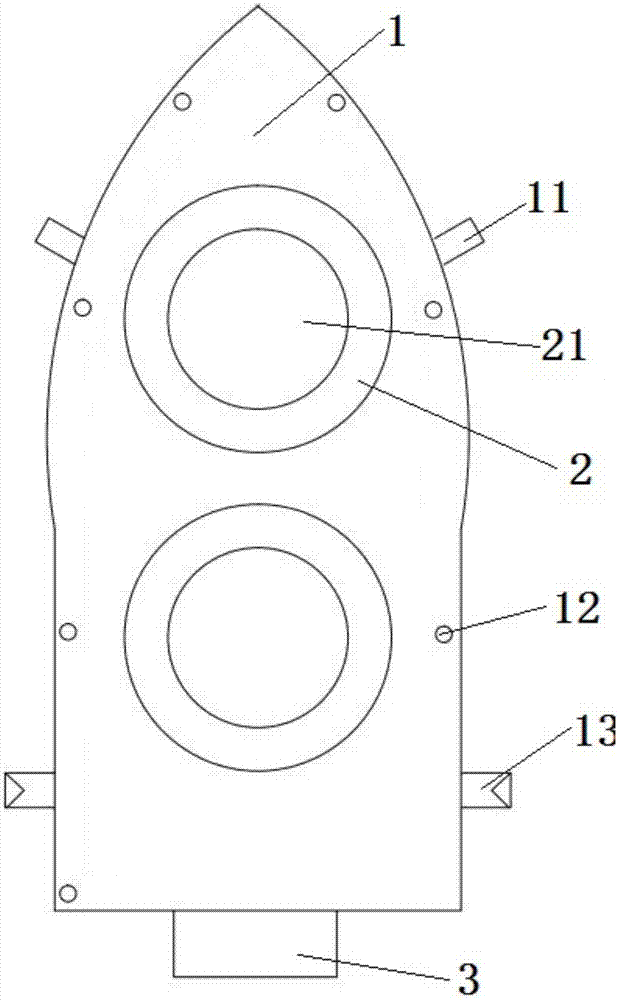

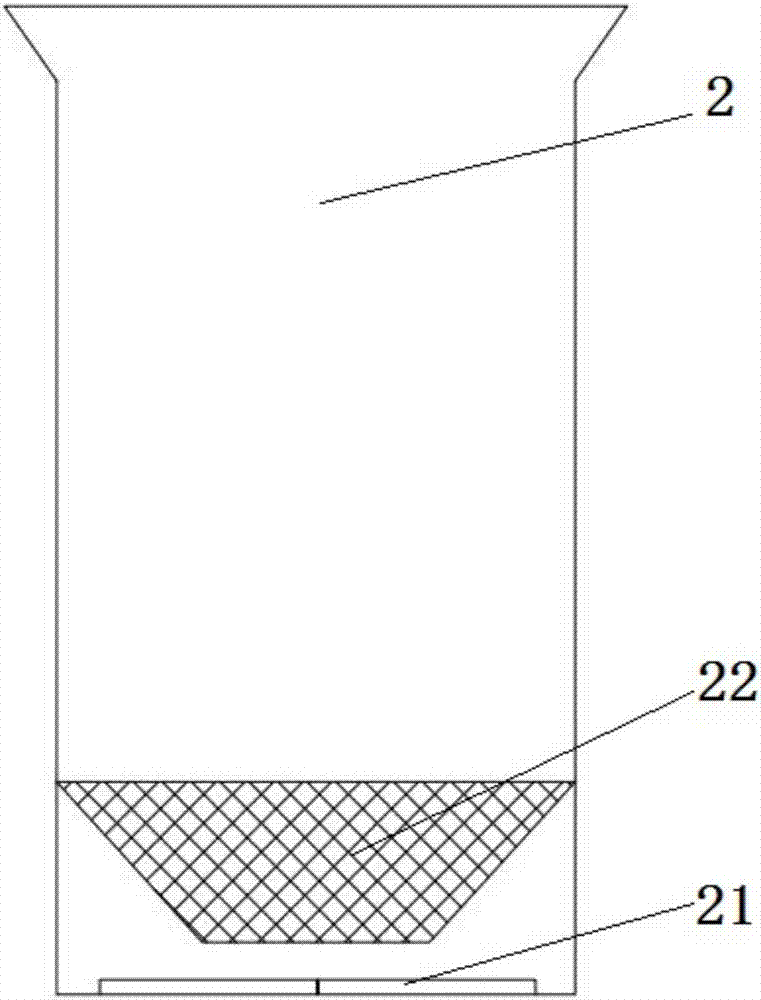

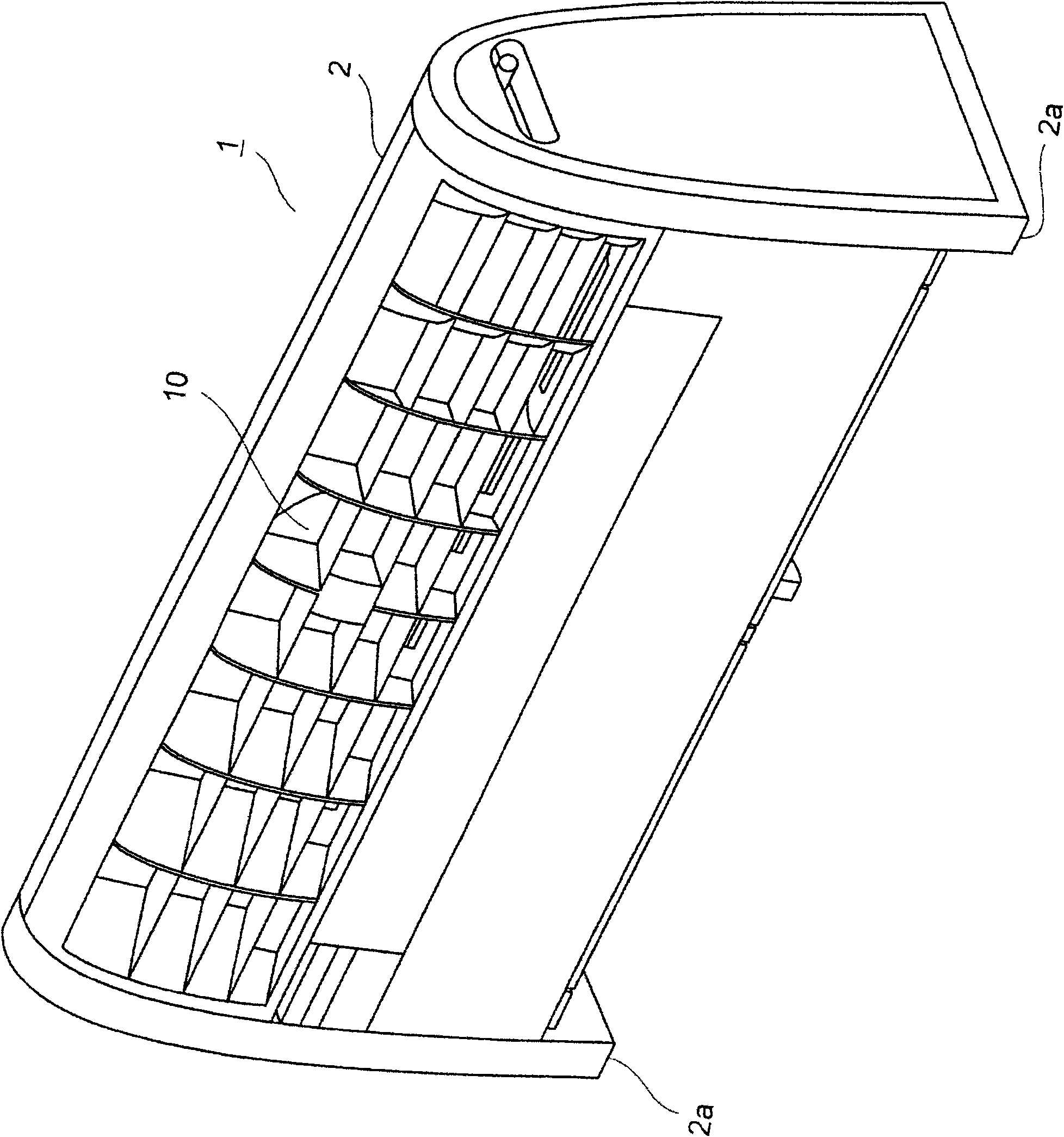

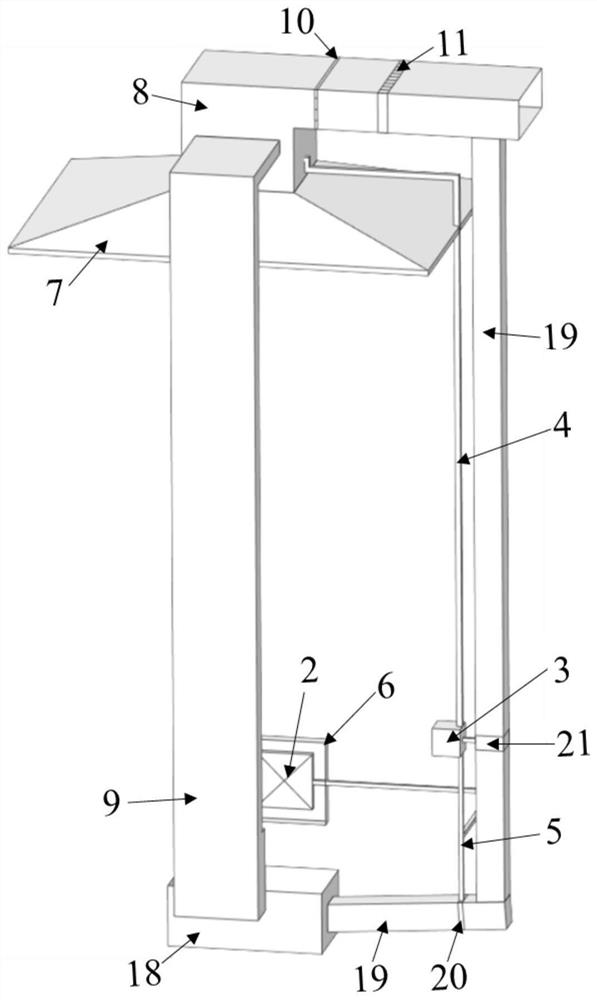

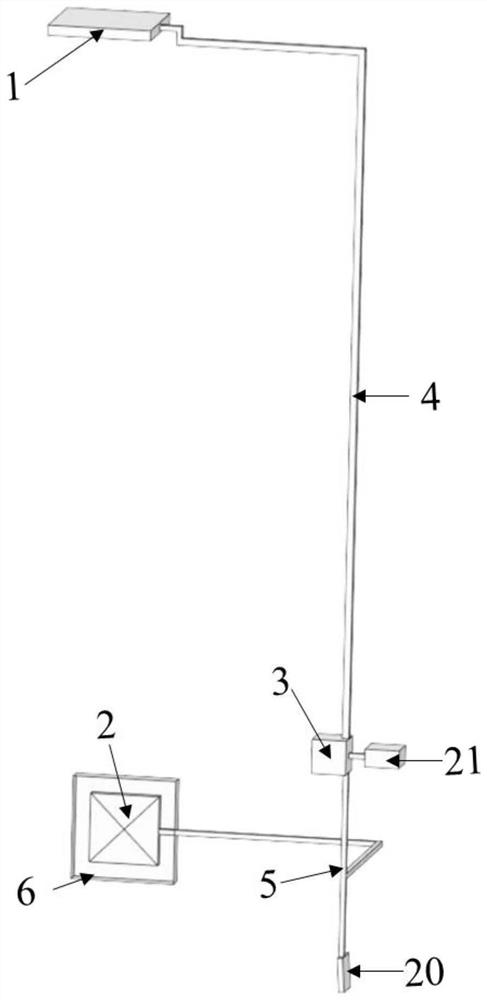

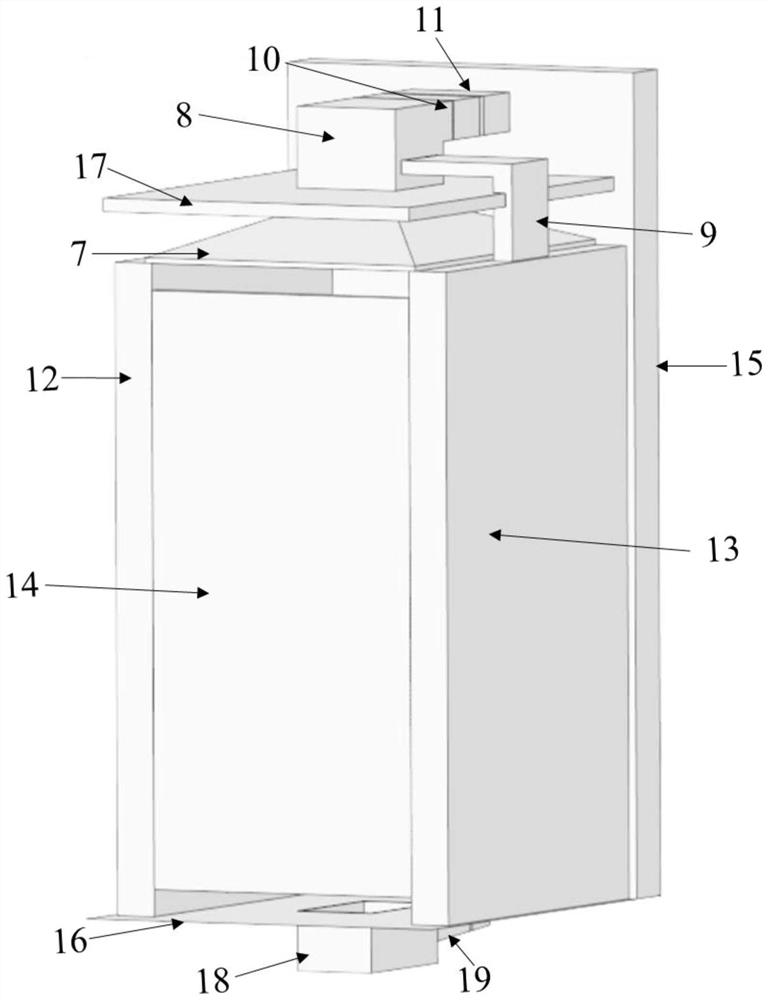

High intelligent high safety performance novel silent range hood

InactiveCN108916932AOmission will notPrevent proliferationDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke

The invention provides a novel silent range hood with high intelligence and high safety performance. The range hood comprises a main body of the range hood, an air curtain machine installed at a lowerpart of the main body of the range hood, and an exhaust fan disposed at an upper part of the range hood; the main body of the range hood is provided with a power source, a controller, a temperature sensor for monitoring an ambient temperature state, and a smoke sensor for real-time feedback of the smoke condition; an air curtain machine includes an air curtain exhaust fan and an air outlet opening at the periphery of the air curtain machine for forming a wind curtain, The air curtain exhaust fan extracts the external air, and the external air reaches an air outlet position by communicating with the air curtain exhaust fan and an air channel of the air outlet opening of the air curtain machine, and the air sprayed at the air outlet forms the wind curtain. The design of the range hood allows the smoke cover to be invisible, prevents smoke from diffusion, and provides the user more visual and free space, ensures that the smoke does not spread and leak, the overall flow rate of the exhaust is low, the air flow rate is low, the impact on cooktop flame and cooking experience is small, and the use is safer.

Owner:李云飞

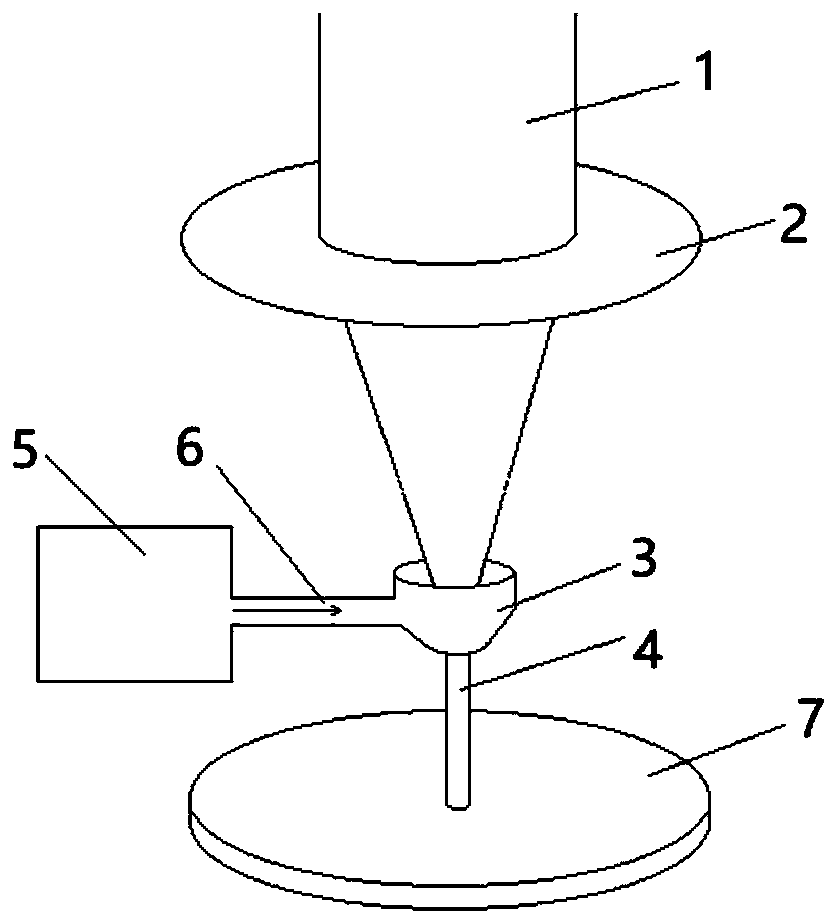

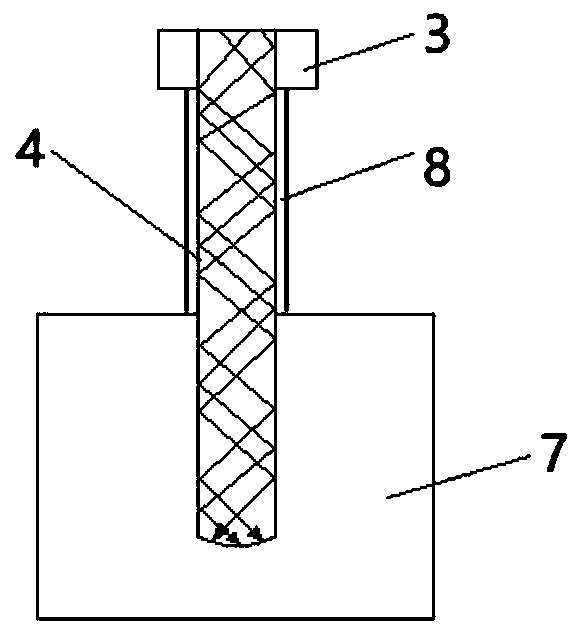

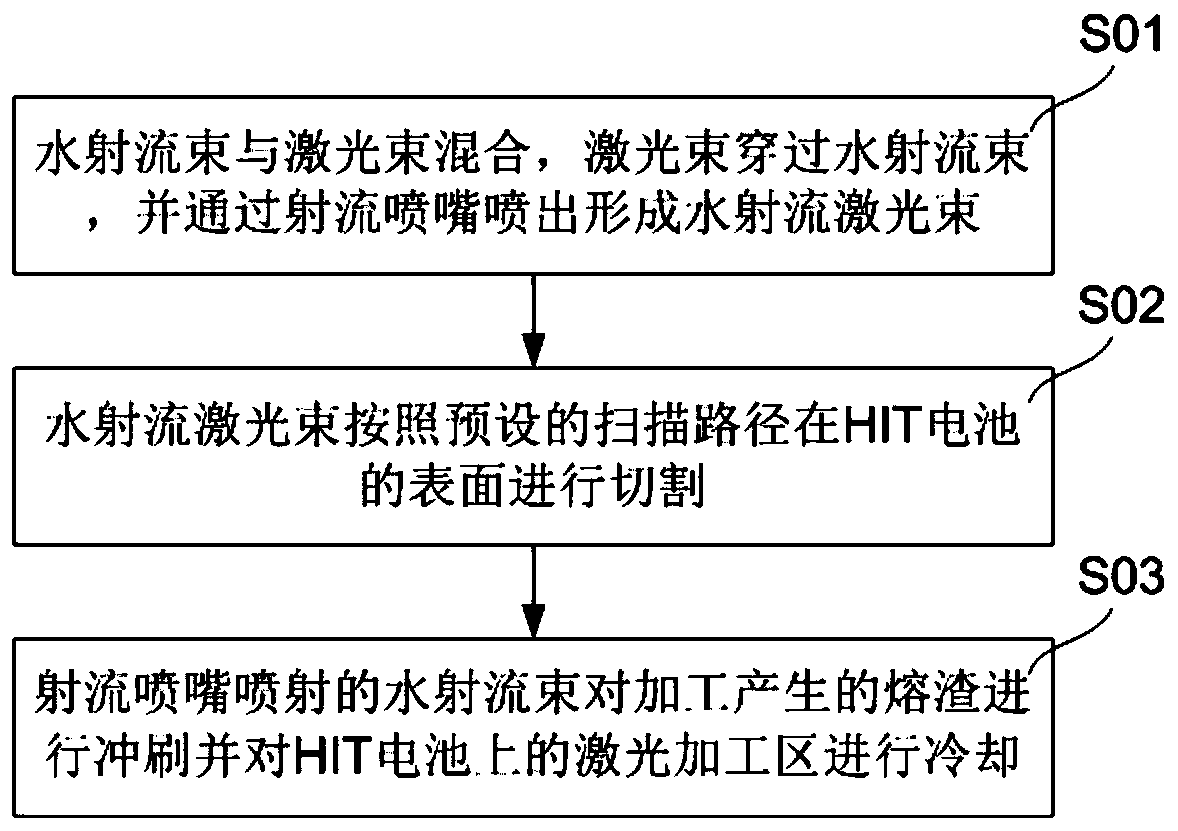

Low-temperature cutting method and device suitable for HIT battery

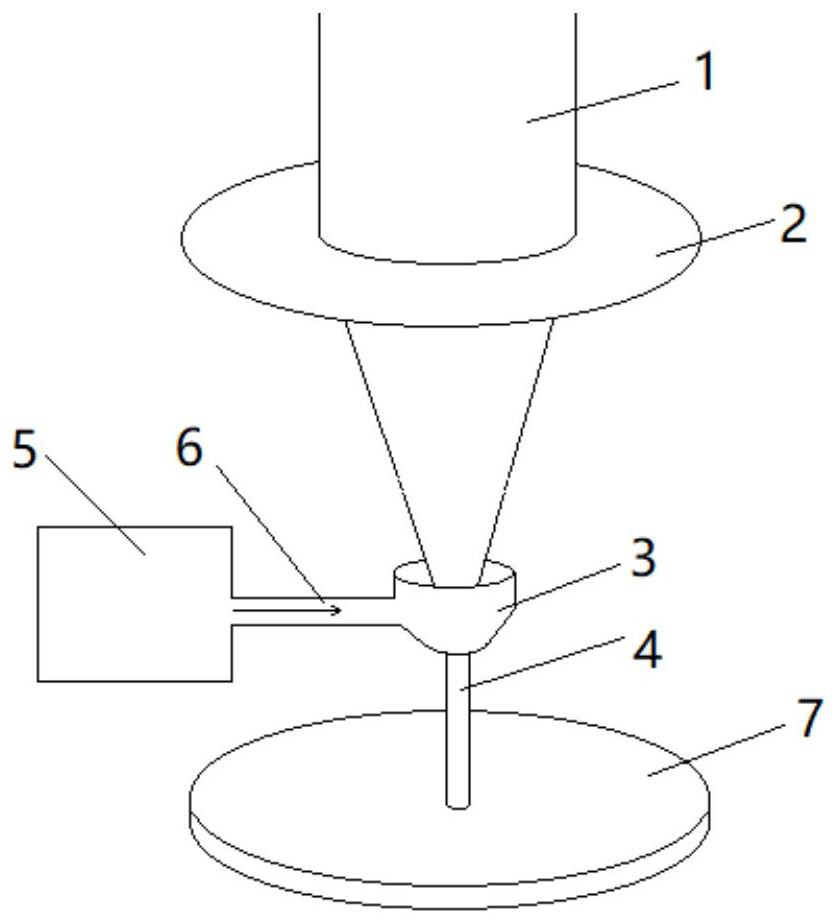

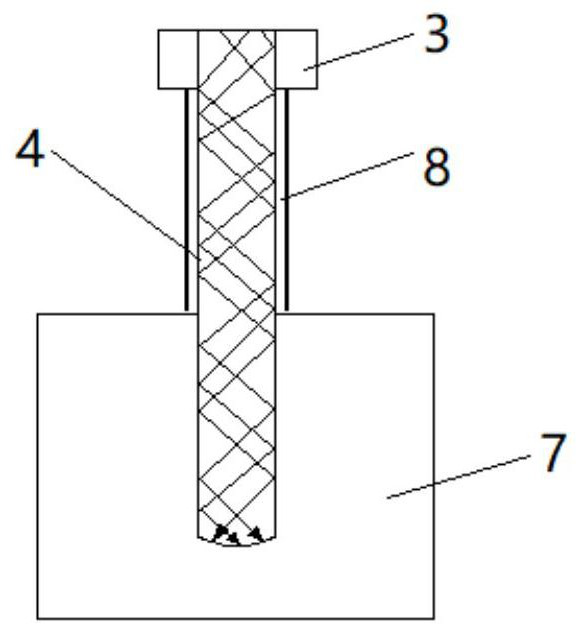

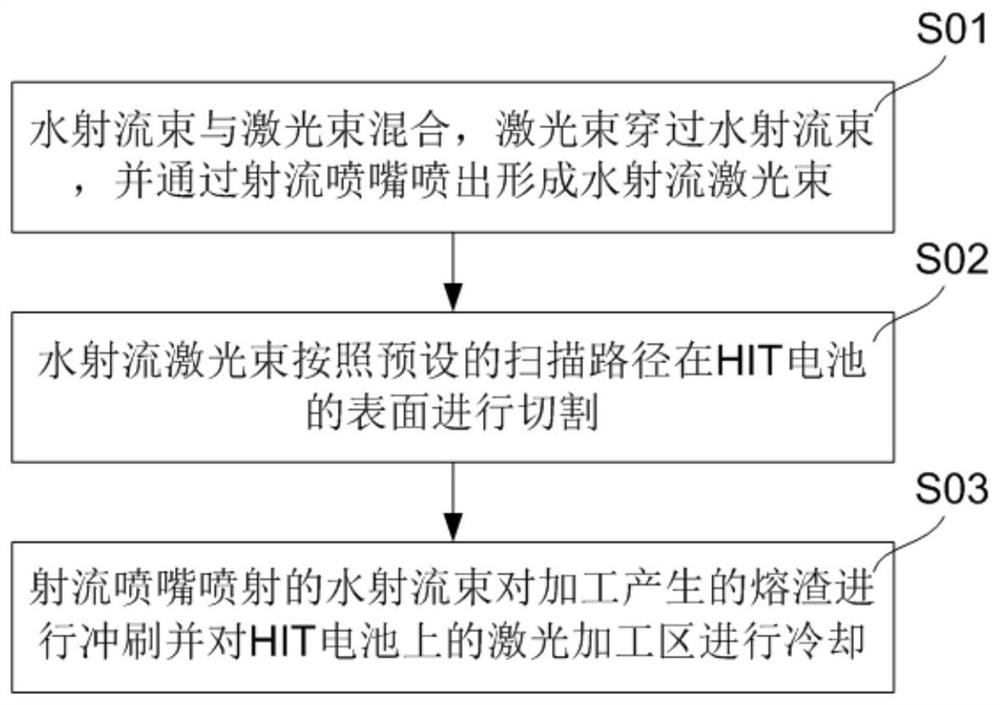

ActiveCN110788483AReduce performanceReduce depositionLaser beam welding apparatusLaser processingJet flow

The invention provides a low-temperature cutting method and device suitable for an HIT battery. The method comprises the steps that a water jet flow beam and a laser beam are mixed, the laser beam penetrates through the water jet flow beam, and is sprayed out through a jet flow nozzle, and a water jet flow laser beam is formed; the water jet flow laser beam carries out cutting on the surface of the HIT battery according to the preset scanning path; and the water jet flow beam sprayed out of the jet flow nozzle carries out washing on molten slag generated by machining, and the laser machining area on the HIT battery is cooled. The efficiency losses of cutting to the HIT battery can be greatly reduced, through the high-speed water jet flow beam, the laser machining area is cooled, washing iscarried out, a re-casting layer is reduced, and the surface and the cross section of the HIT battery obtained after cutting are free of casting layer, hot stress and micro cracks.

Owner:上海润势科技有限公司

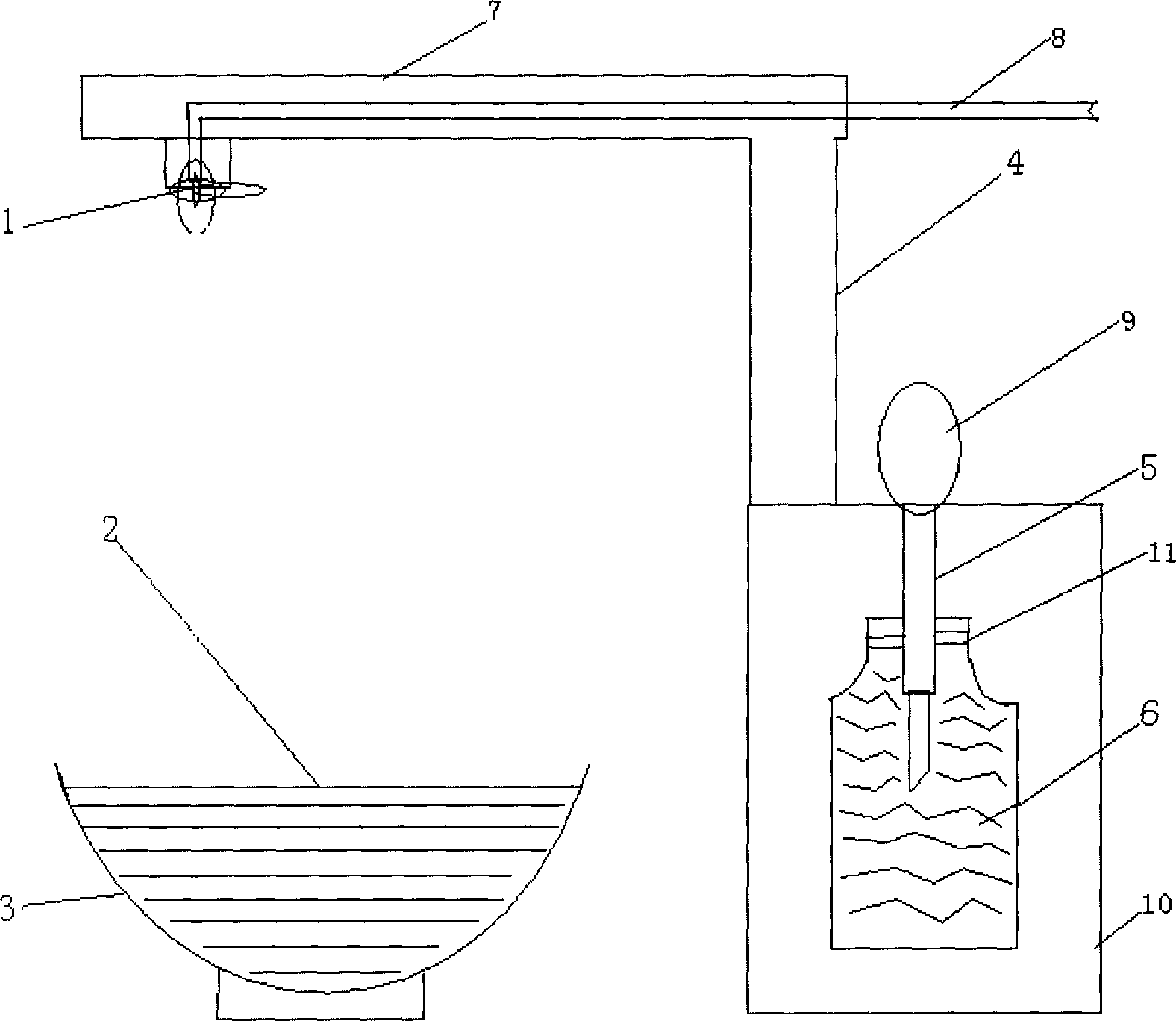

True and false sesame oil detection device

A true and false sesame oil detection device includes a box, a bracket is mounted on the box, a cross bar is mounted on the bracket, a water pipe is mounted in the cross bar, the water pipe is connected with a water tap, a bowl is arranged below the water pipe, clean water is put in the bowl, an oil bottle is installed in the box, sesame oil is installed in the oil bottle, the sesame oil is connected with a straw, and a suction ball is mounted on the straw top. The true and false sesame oil detection device can accurately detect the true and false sesame oil. If the sesame oil is true, the sesame oil in the water may quickly spread, and if the sesame oil is false, the sesame oil may not quickly spread, and gathers in a drop. The true and false sesame oil detection device can detect if the sesame oil is true or false, so that the general public may not be tricked to buy products which are fake.

Owner:徐懿

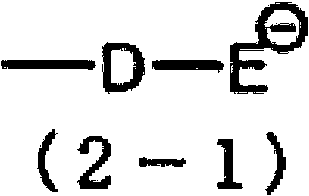

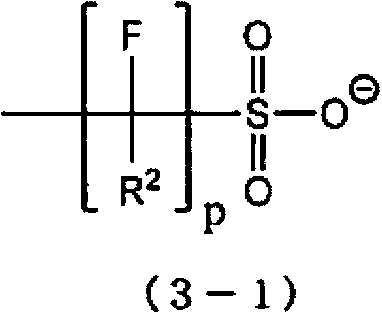

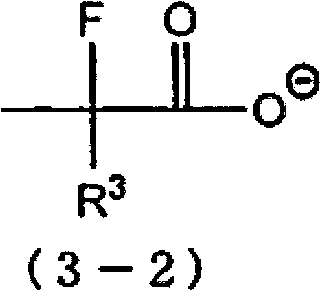

Silicon compound, condensation product, resist compostion and pattern formation method

InactiveCN103130826AHigh acid strengthHigh sensitivityGroup 4/14 element organic compoundsPhotomechanical exposure apparatusResistHigh energy

Owner:CENT GLASS CO LTD

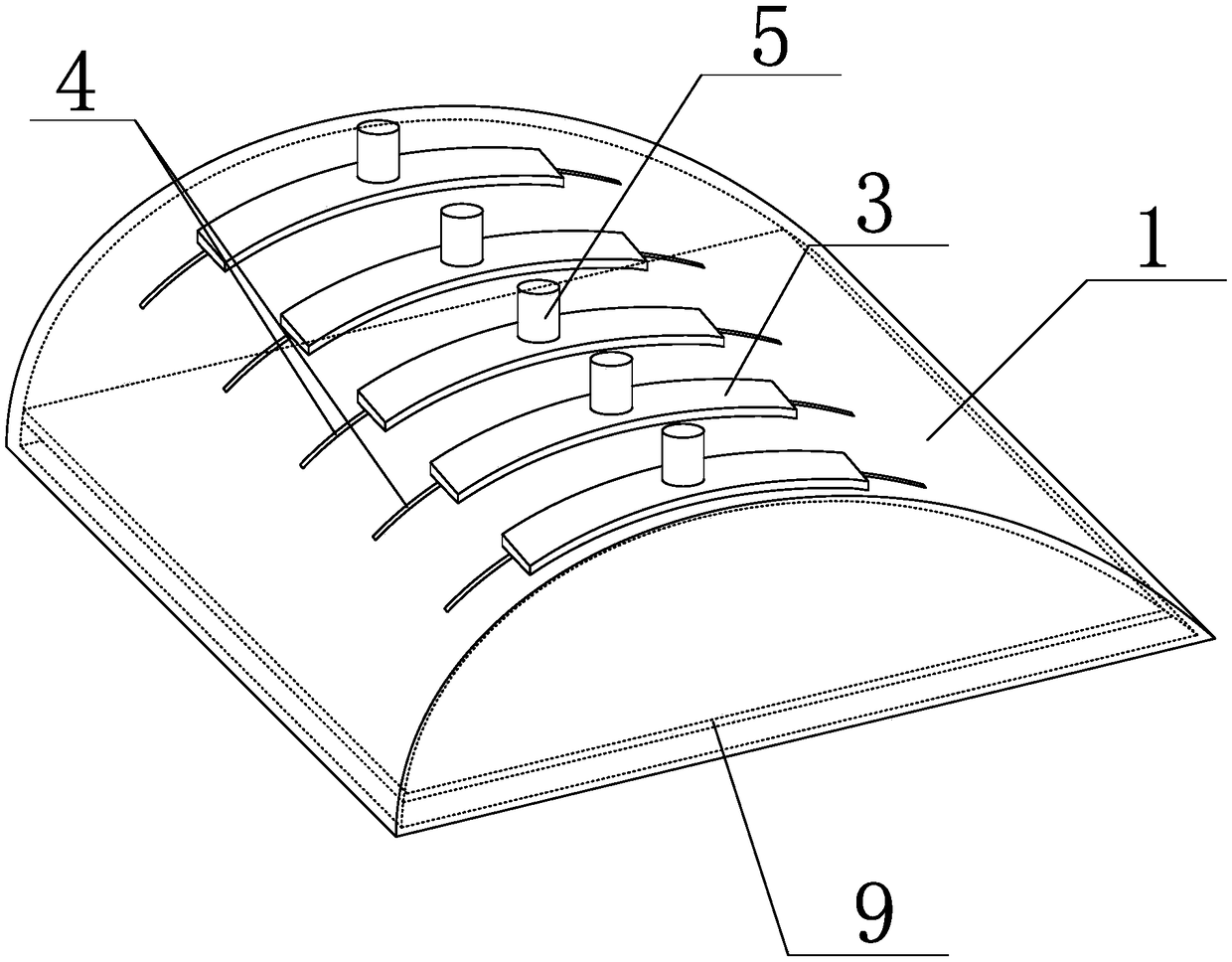

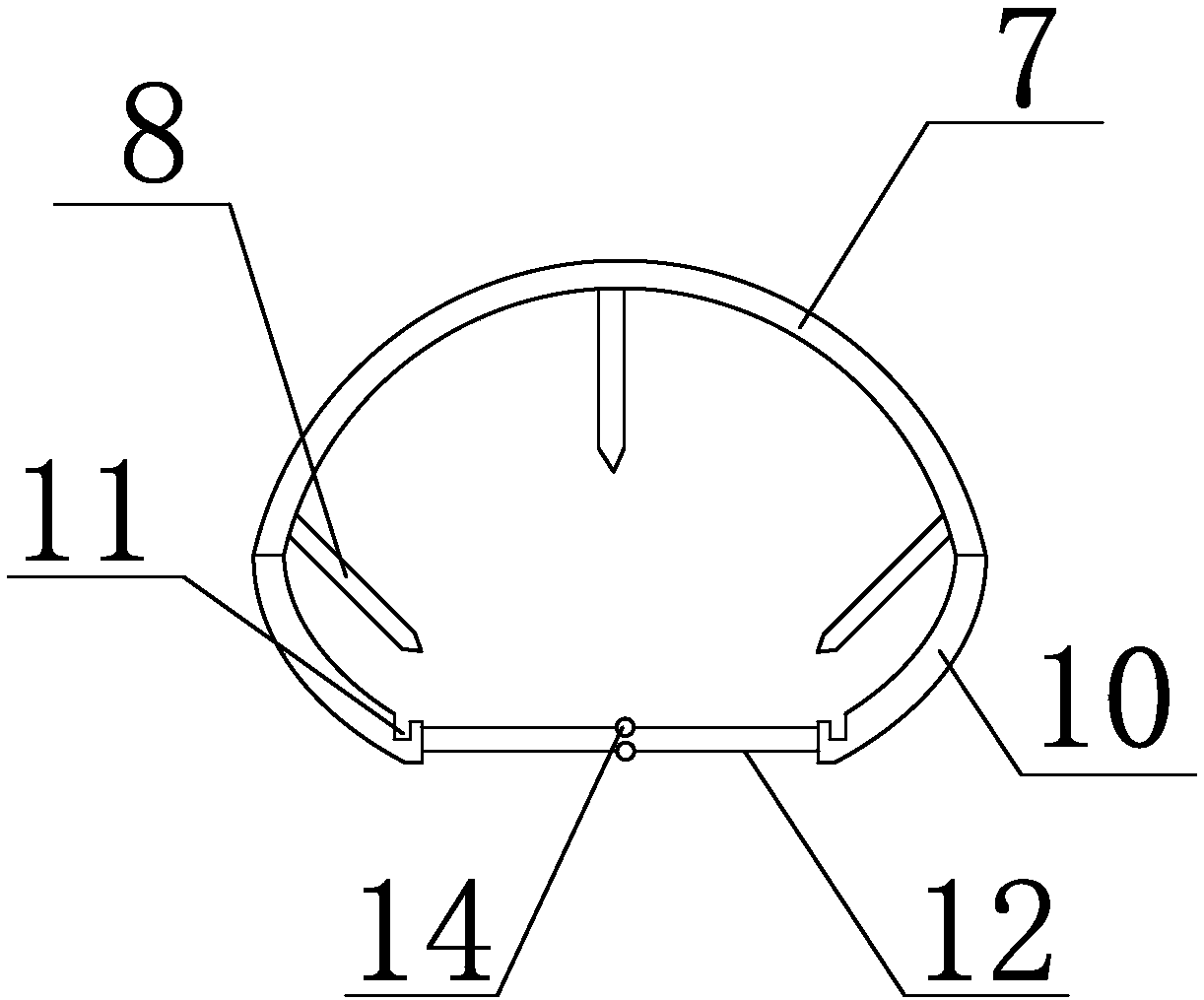

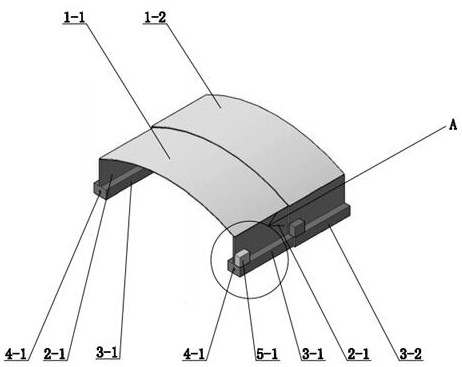

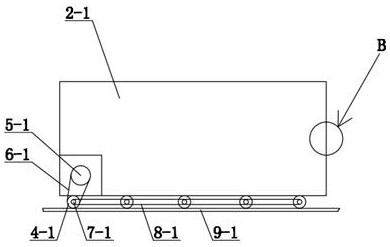

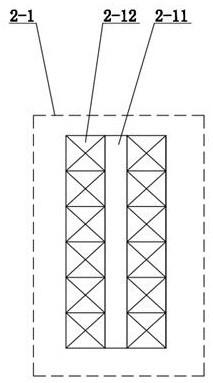

Paint spraying device capable of improving spraying quality

InactiveCN108906451APrevent proliferationDiffusion will notSpray nozzlesSpray boothsLacquerEngineering

The invention discloses a paint spraying device capable of improving spraying quality. The paint spraying device capable of improving spraying quality comprises a semi-cylindrical shield, wherein an opening is formed in the square bottom surface of the shield; a plurality of strip-shaped slots are formed in the arc-shaped top plate of the shield; a movable plate is arranged above each strip-shapedslot in parallel; chutes are separately formed in two ends of each strip-shaped slot; sliding blocks are arranged at two ends of the lower surface of each movable plate; the sliding blocks are clamped in the chutes and are slidably connected with the bottom surfaces of the chutes; the middle of each movable plate is perpendicularly connected with an operation tube; a feeding tube is inserted in each operation tube; the lower end of each feeding tube is connected with a spraying plate which is parallel to the axis of the shield; three spraying tubes are successively arranged on the inner wallof each spraying plate in the peripheral direction; and a wavy screen board is arranged at the position, which is close to the opening of the bottom surface, in the shield. By the paint spraying device, paint can be prevented from being diffused in air during paint spraying, the distance between a paint spraying opening and a sprayed surface is limited to a certain degree, and the circumstance that spraying thickness of different regions are uneven due to human factors can be avoided.

Owner:江苏双聚智能装备制造有限公司

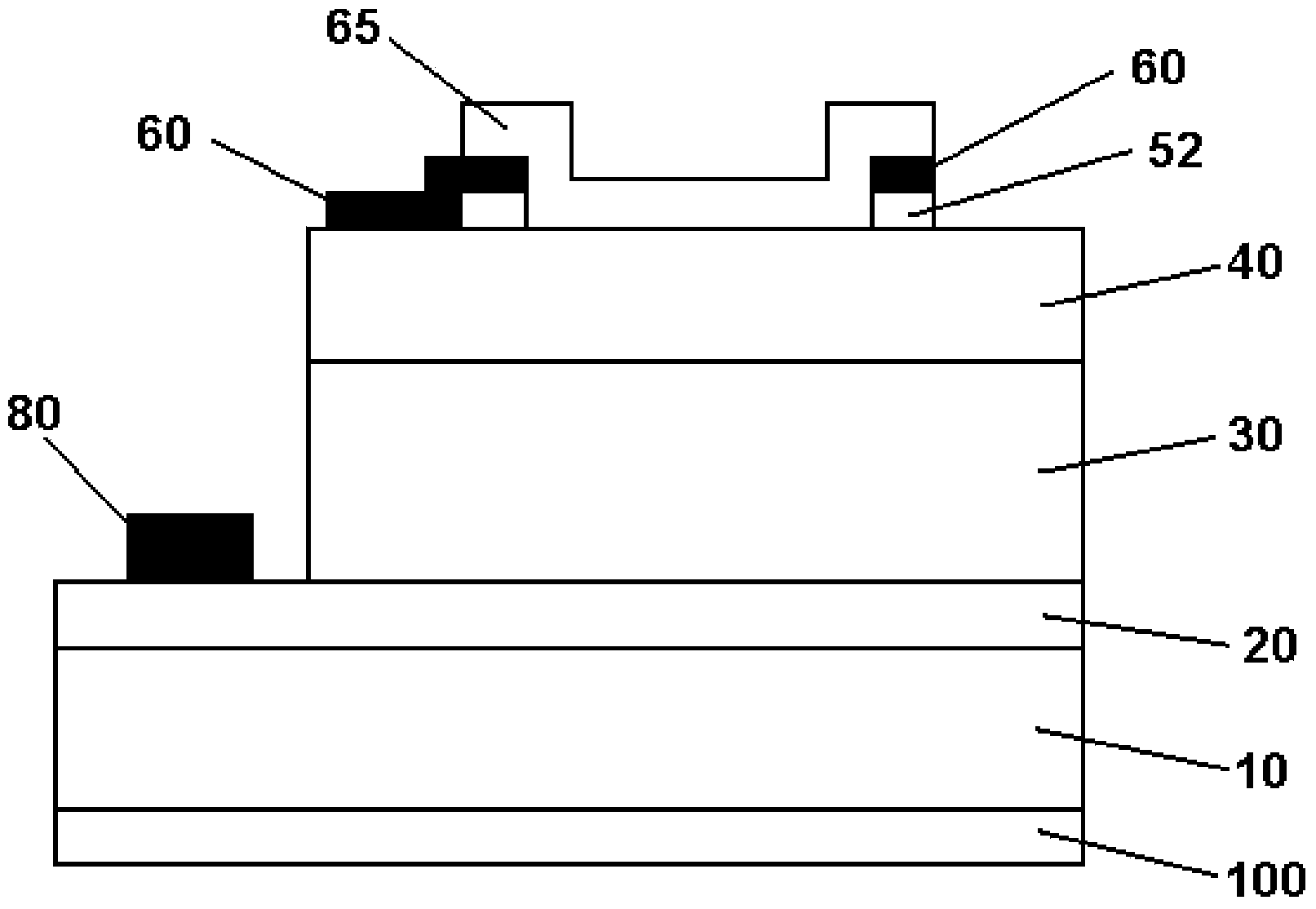

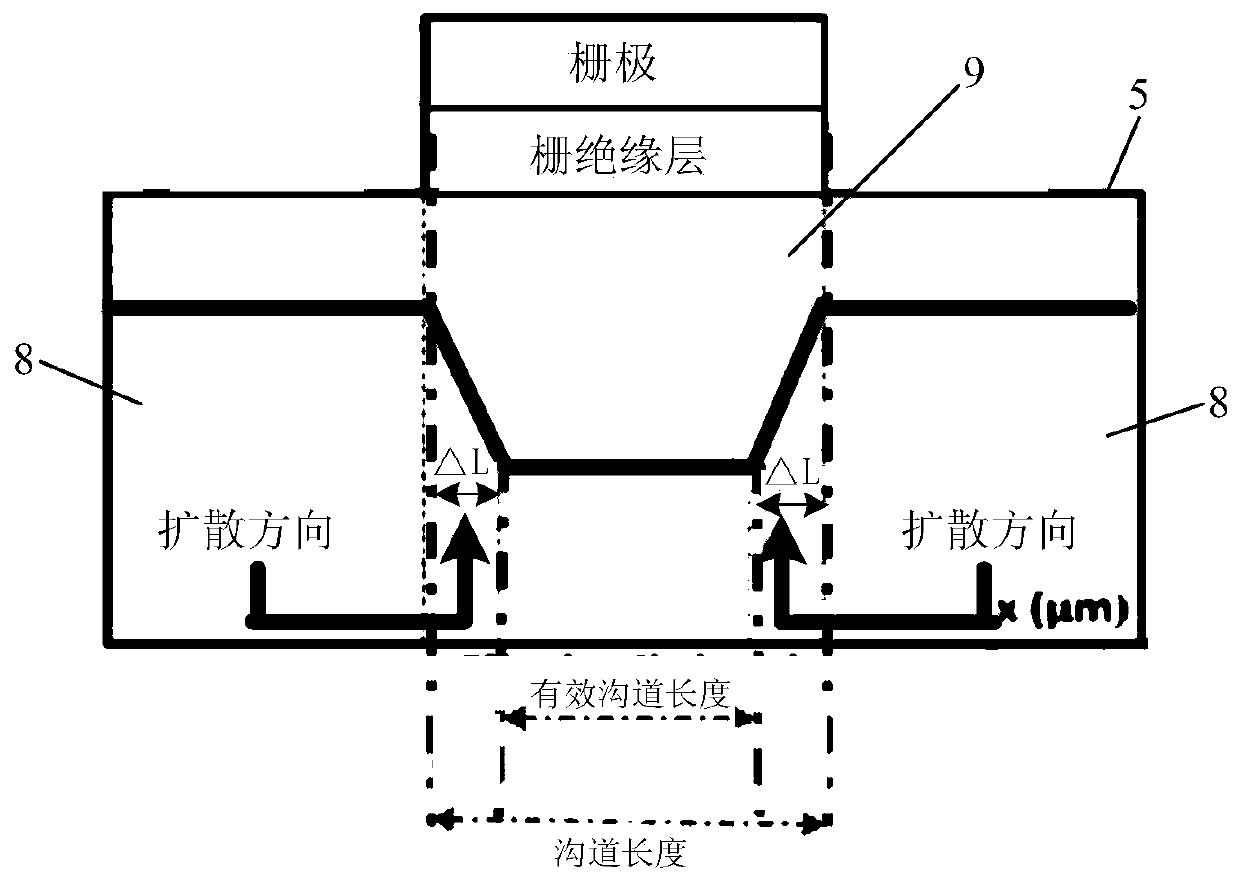

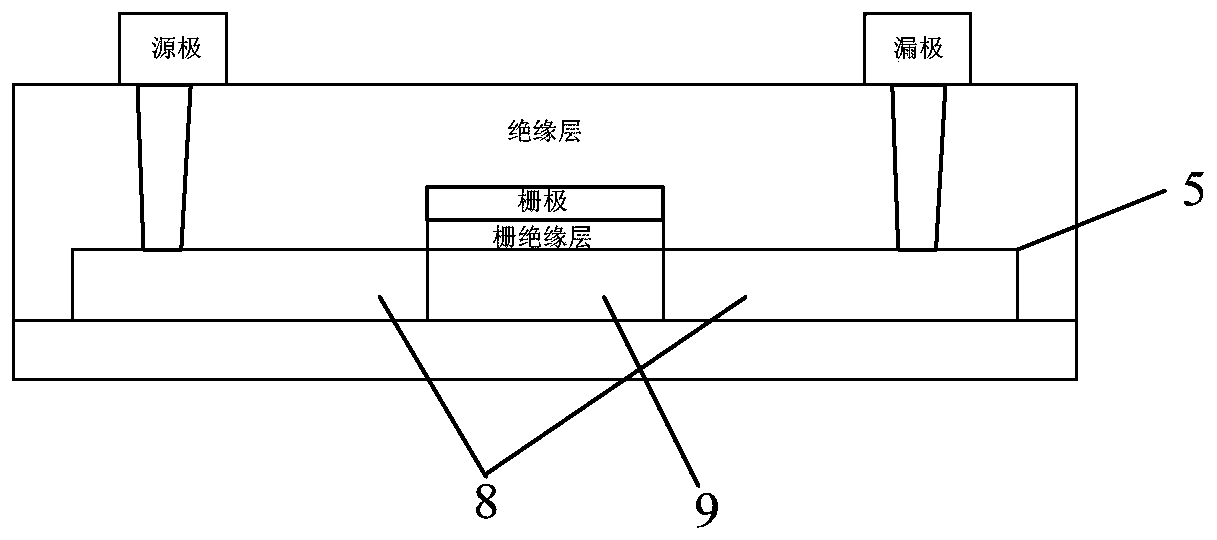

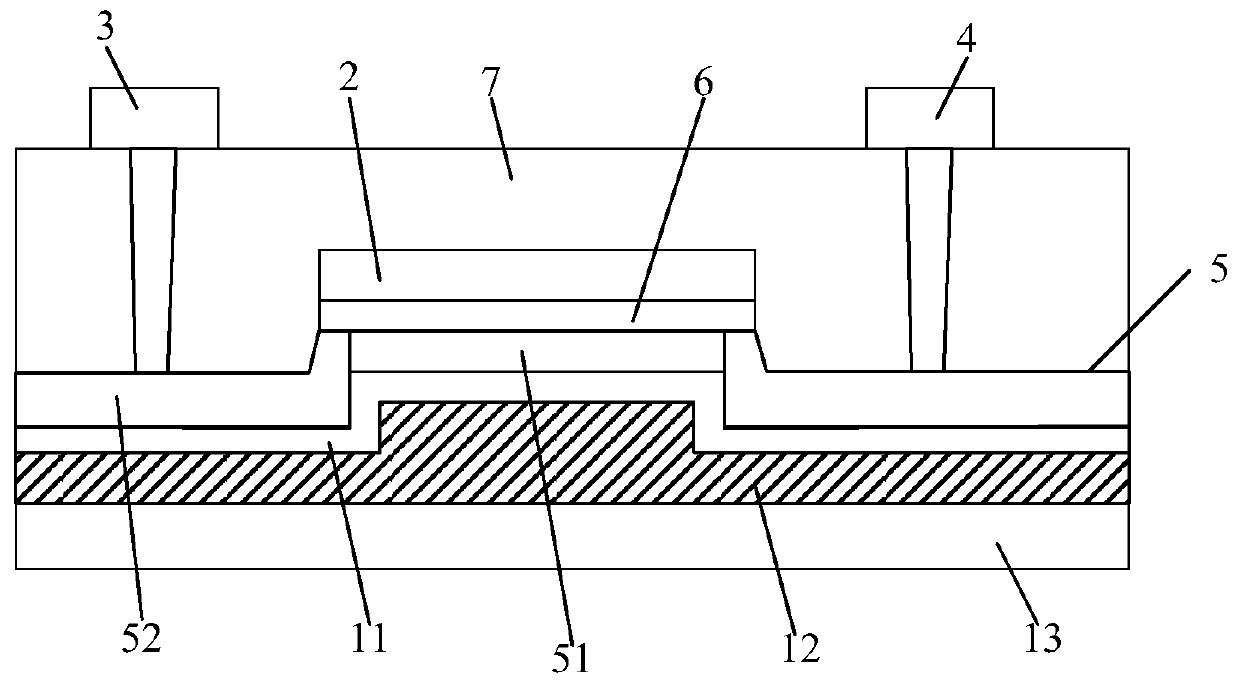

Transistor and preparation method thereof, display substrate and display device

PendingCN109860307ADoes not shorten the effective channel lengthPoor improvementTransistorSolid-state devicesSemiconductor materialsDisplay device

The invention provides a transistor, a preparation method thereof, a display substrate and a display device. The transistor comprises a substrate structure, a gate electrode, a source electrode, a drain electrode and an active layer, wherein the gate electrode, the source electrode, the drain electrode and the active layer are arranged on the substrate structure. The gate electrode, the source electrode and the drain electrode are all located at one side, deviating from the substrate structure, of the active layer. The active layer comprises a first region corresponding to an orthographic projection region of the gate electrode on the substrate structure and a second region located outside the orthographic projection region, wherein the second region is made of a conductive semiconductor material, and the surface, in contact with the first region, of the substrate structure and the surface, in contact with the second region, of the substrate structure are not in the same plane. The surface, in contact with the first region, of the substrate structure and the surface, in contact with the second region, of the substrate structure are not in the same plane, so the transistor enables the height difference to be formed between the first region and the second region of the active layer, and the diffusion path of an active layer material from the second region to the first region in the conductor formation is lengthened, and the diffusion of the active layer material needs greater energy, thereby improving the poor threshold voltage uniformity of the transistor caused by the short-channel effect.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

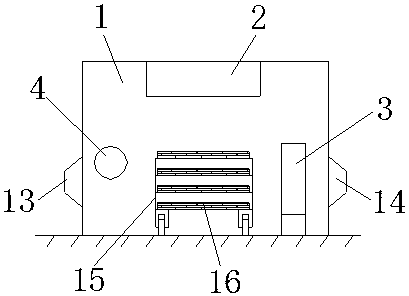

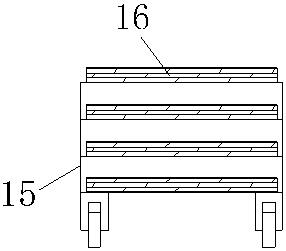

Device and method for producing customized closets

InactiveCN107599107AImprove indoor space utilizationMeet actual needsDrilling machinesDispersed particle separationPersonalizationDecomposition

The invention discloses a device and method for producing customized closets. The device comprises a computer plate carrying saw, a digital controlled drilling machine, a digital controlled milling machine, a plate transferring vehicle, a plate free formaldehyde release and decomposition unit, a free formaldehyde decomposition agent spraying unit, a free formaldehyde decomposition agent filling unit, an edge sealing machine and a packaging unit. According to the device and method, efficient production of the customized closets can be achieved, the intelligent and automatic degree in the production and machining process can be high, the requirements of consumers for the environment-friendly customized closets can be met, health of the consumer of the customized closets is guaranteed, and individuation and humanization service features of the customized closets can be achieved.

Owner:武汉汉慧宝驰家居有限公司

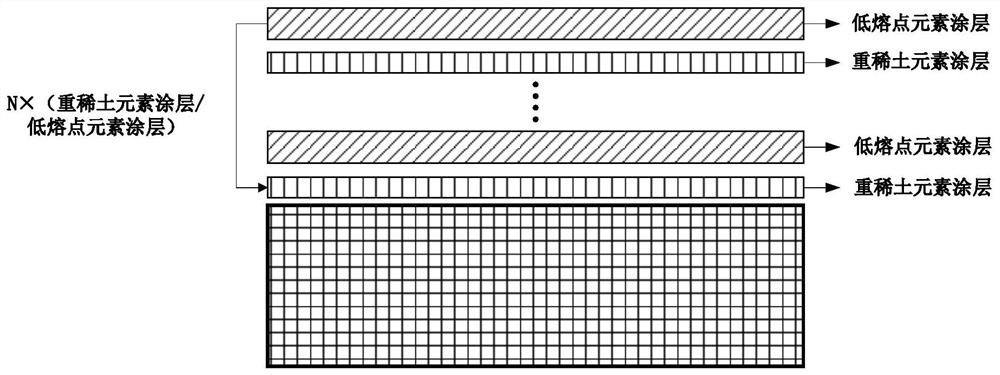

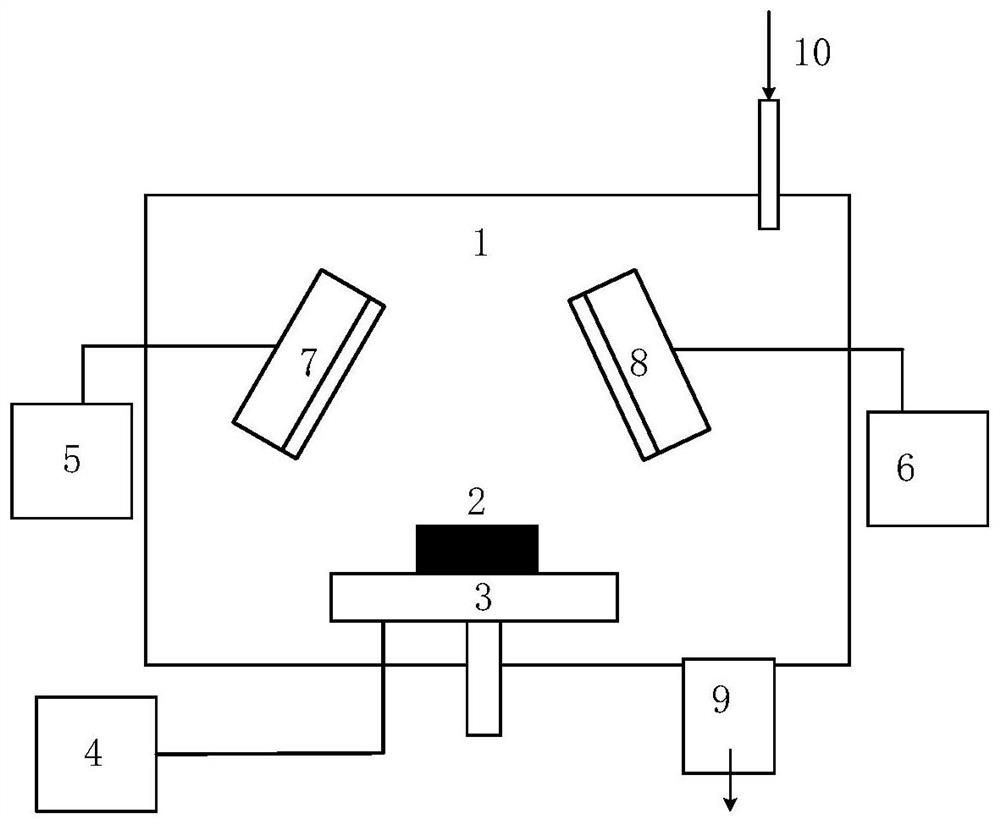

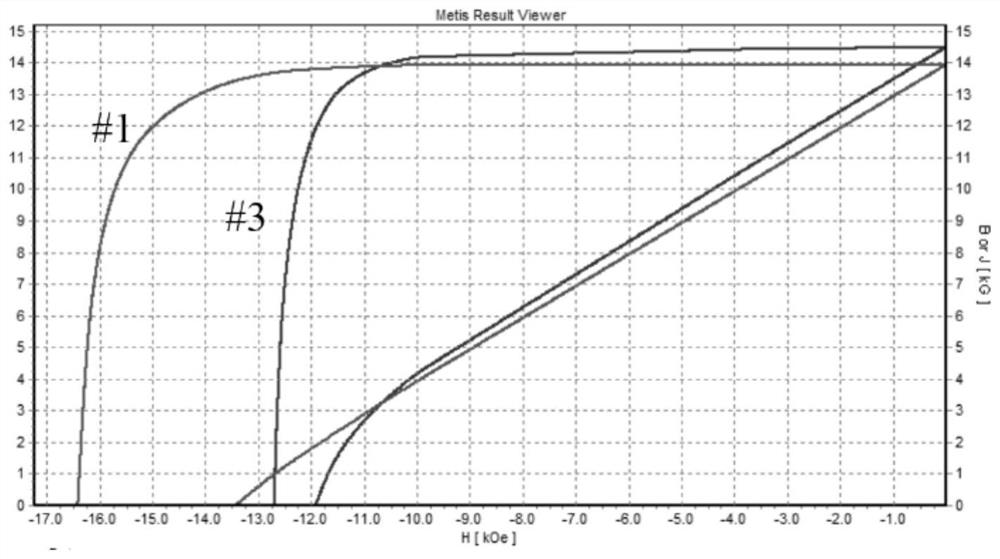

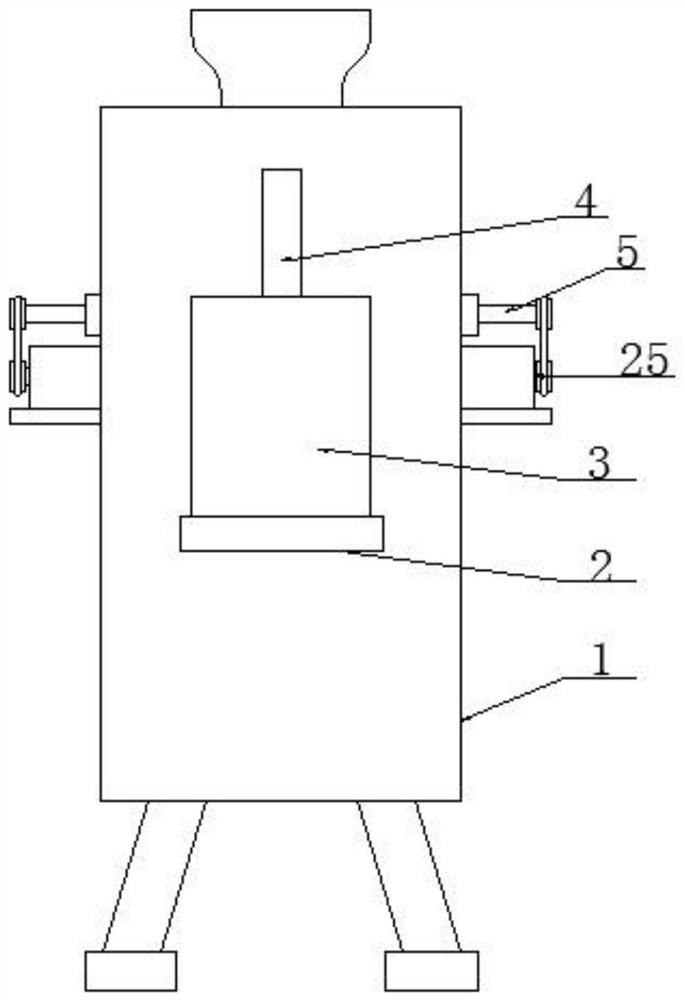

Method for diffusing multi-element heavy rare earth on sintered neodymium-iron-boron magnet grain boundary

ActiveCN113314327AFacilitated DiffusionDiffusion will notInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementSurface engineering

The invention belongs to the technical field of sintered neodymium-iron-boron magnet surface engineering, and aims to provide a method for diffusing multi-element heavy rare earth on a sintered neodymium-iron-boron magnet grain boundary in order to solve the problems in manufacturing and application of a multi-element heavy rare earth alloy target material in the prior art. Firstly, multiple coatings are prepared on the surface of a sintered NdFeB magnet through the magnetron sputtering technology, the first coating is a heavy rare earth coating such as Dy or Tb, and the second coating is a low-melting-point coating such as Al. And subsequent coating is performed, and the first coating and the second coating are repeated according to the requirements of a grain boundary diffusion process. After the coating is prepared, a magnet is put into a vacuum diffusion furnace, and gradient temperature heating is conducted on the magnet. A multi-element heavy rare earth alloy coating is formed on the surface of the NdFeB magnet through first-stage vacuum heat treatment, and synergistic diffusion of low-melting-point elements and heavy rare earth elements in grain boundaries of the sintered NdFeB magnet is achieved through second-stage vacuum heat treatment. And finally, tempering treatment is carried out, so that the coercive force of the sintered NdFeB magnet is improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

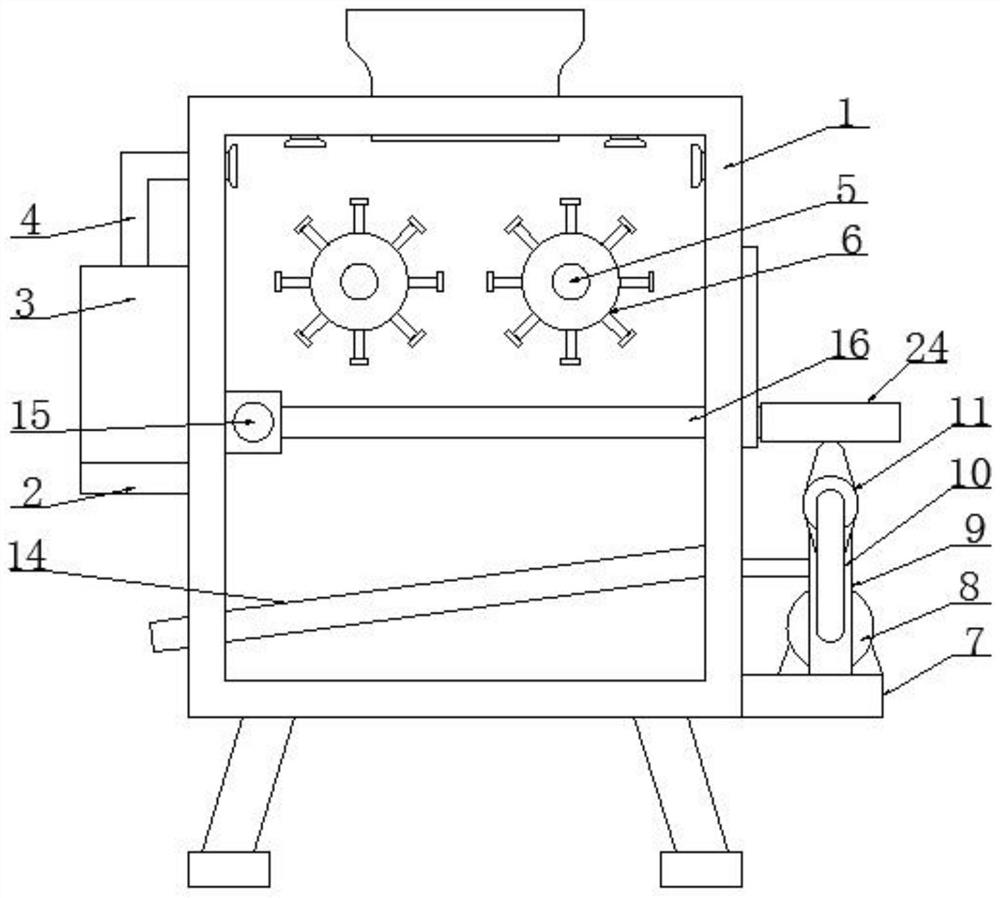

Refining mechanism for mining machinery

InactiveCN112495280AWell mixedPrevent proliferationShaking/oscillating/vibrating mixersRotary stirring mixersTransmission beltElectric machinery

The invention relates to the technical field of mining equipment, and discloses a refining mechanism for mining machinery. The refining mechanism comprises a box body, a first support plate, a secondsupport plate and a power mechanism are fixedly mounted on the two sides of the box body correspondingly, a suction fan is fixedly mounted at the top of the first support plate, and a pipeline is fixedly mounted at the top of the suction fan. According to the refining mechanism for mining machinery, the power mechanism drives a first rotating shaft to drive an overturning roller to rotate, mineralaggregate in the box body is driven to overturn when the overturning roller rotates, when the mineral aggregate is located on a vibrating plate, a motor rotates to drive a transmission belt to rotatethrough an output shaft, the transmission belt drives a cam to rotate through a second rotating shaft while rotating, the cam rotates to drive a connecting plate to vibrate up and down, and the connecting plate is fixedly connected with the vibrating plate, so that the vibrating plate can also vibrate up and down, the mineral aggregate in the box body can vibrate up and down and turn over, and the purpose of uniformly mixing the mineral aggregate is achieved.

Owner:LOUDI DINGHONG AUTOMATION EQUIP

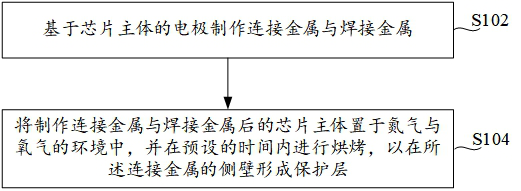

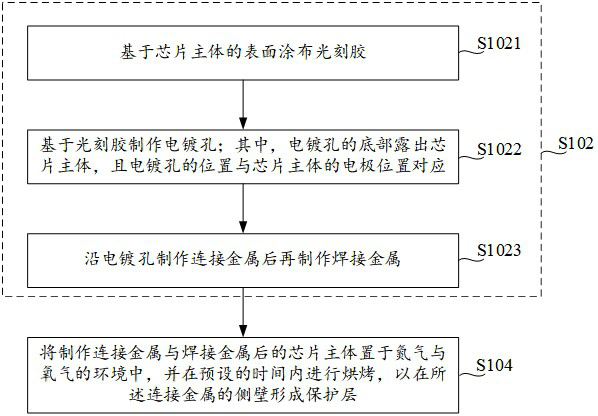

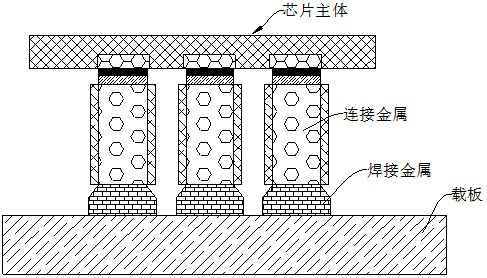

Chip manufacturing method, chip connecting method and chip

InactiveCN114649287AImprove performanceInhibited DiffusionSemiconductor/solid-state device detailsSolid-state devicesProtection layerSemiconductor

The invention provides a chip manufacturing method, a chip connecting method and a chip, and relates to the technical field of semiconductor processes. The method comprises the following steps: firstly, manufacturing connecting metal and welding metal based on an electrode of a chip main body, then placing the chip main body after the connecting metal and the welding metal are manufactured in a nitrogen and oxygen environment, and baking within a preset time to form a protective layer on the side wall of the connecting metal, the protective layer is used for inhibiting diffusion of welding metal to connecting metal during welding. The chip manufacturing method, the chip connecting method and the chip provided by the invention have the advantage of better performance after welding.

Owner:甬矽半导体(宁波)有限公司

Submerged type water surface floating garbage cleaning device

InactiveCN107119647AImprove adsorption capacityImprove fishing efficiencyWater cleaningImpellerWater channel

The invention discloses a submerged type water surface floating garbage cleaning device. The submerged type water surface floating garbage cleaning device comprises a hollow closed shell body. The bottom of the shell body is provided with water inlet pipes used for filling water into the shell body. The top of the shell body is provided with air exhausting pipes used for exhausting air to the outside of the shell body. Control valves are arranged on the water inlet pipes and the air exhausting pipes. The middle of the shell body is provided with at least one through vertical water channel. An impeller which can horizontally rotate is arranged at the bottom of each vertical water channel. A salvaging net used for collecting floating objects is fixed in the position, above the corresponding impeller, in each vertical water channel. The submerged type water surface floating garbage cleaning device has the advantages of being high in salvaging efficiency, capable of preventing garbage diffusion, small in size, high in safety and the like.

Owner:张思琪

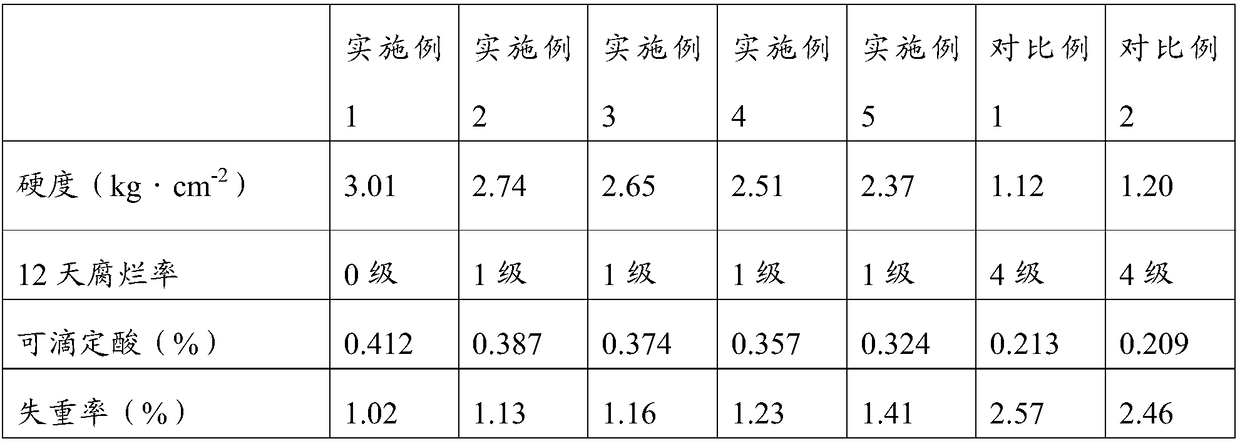

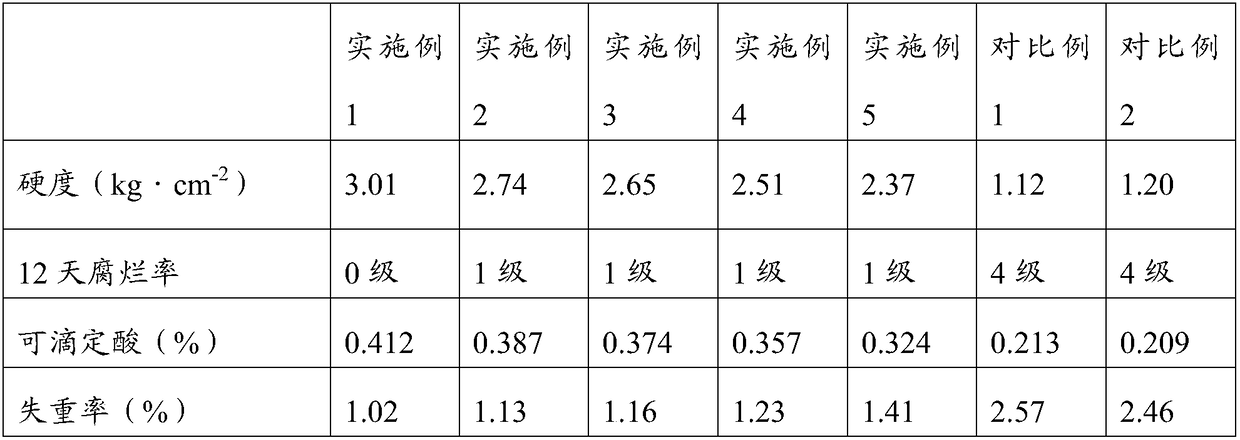

Mould-proof preservative film and preparation method thereof

ActiveCN108559326AGood chemical stabilityImprove mildew resistanceAntifouling/underwater paintsPaints with biocidesWater vaporDissolution

The invention relates to a mould-proof preservative film and a preparation method thereof. The mould-proof preservative film comprises a base film and a mould-proof and fresh-keeping coating arrangedon the base film, the mould-proof and fresh-keeping coating is made of mould-proof and fresh-keeping coating, and the mould-proof and fresh-keeping coating is prepared from the following raw materialsin parts by mass: 60-65 parts of resin, 5-10 parts of mould-proof agent, 30-35 parts of solvent and 0.3-2 parts of auxiliary agent, wherein the resin is composed of the following components in percentage by mass: 28-32% of ethylene-vinyl acetate copolymer, 36-40% polyvinylidene chloride, 12-15% ethylene- ethylene alcohol copolymer, 10 to 12% core-shell structural acrylate copolymer and 4-6% IPN structural polyurethane. The mould-proof preservative film can limit the adsorption and dissolution of the water vapor molecules to the maximum extent, effectively limit the external water to enter theinterior of the packaging material, inhibit the occurrence of mould, keep the water content in the package constant, and the mould-proof agent exposes on the surface of the coating in an embedded manner and the purpose of preventing the growth of the microorganism is achieved by eliminating the microorganism or preventing the germination of the microorganism after the contact with the microorganism.

Owner:常德市德源招商投资有限公司

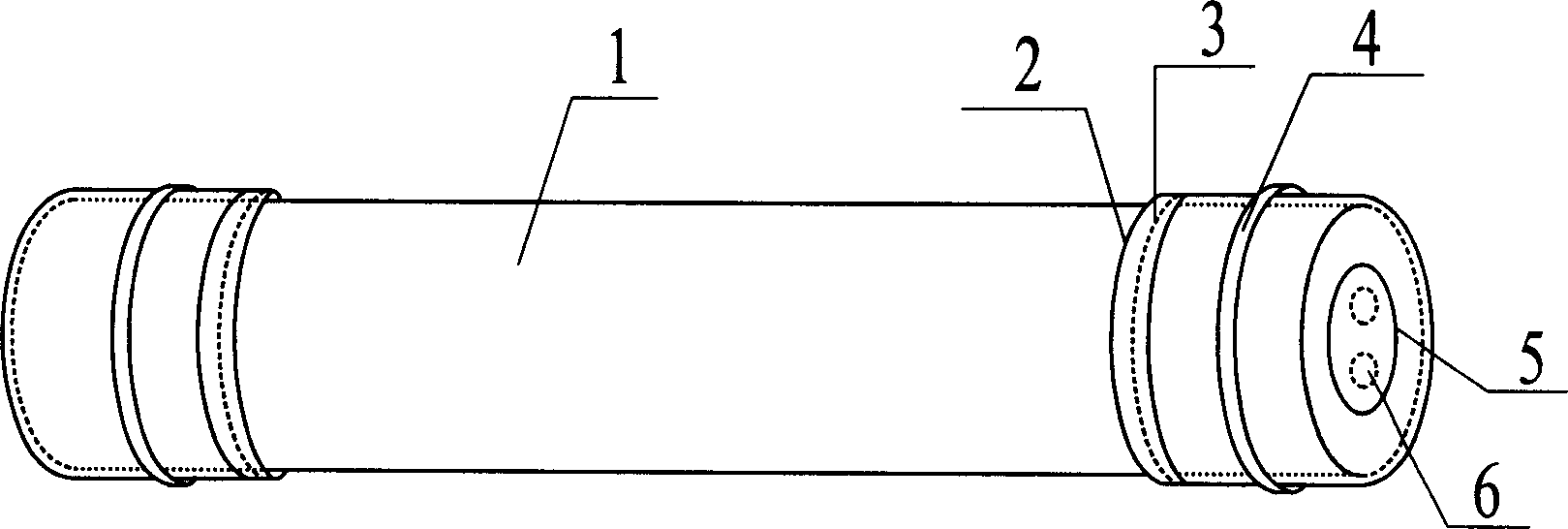

White ant fumigating treating method for log

InactiveCN1552203AImprove adhesionPrevent leakageInsect catchers and killersPolyvinyl chlorideEngineering

A fumigating method for killing the termite in timber includes such steps as adhering the PVC films to both ends of a timber for sealing them, binding the PVC film on the surface of said timber for preventing air leakage, and injecting the fumigant (sulfuryl chloride or methyl bromide) into said timber by use of PQF-I injector. Its advantage is high effect.

Owner:PLANT & FOOD INSPECTION & QUARANTINE TECHN CENT SHENZHEN BUREAU FOR ENTRY & EXIT INSPECTION & QUARANTINE

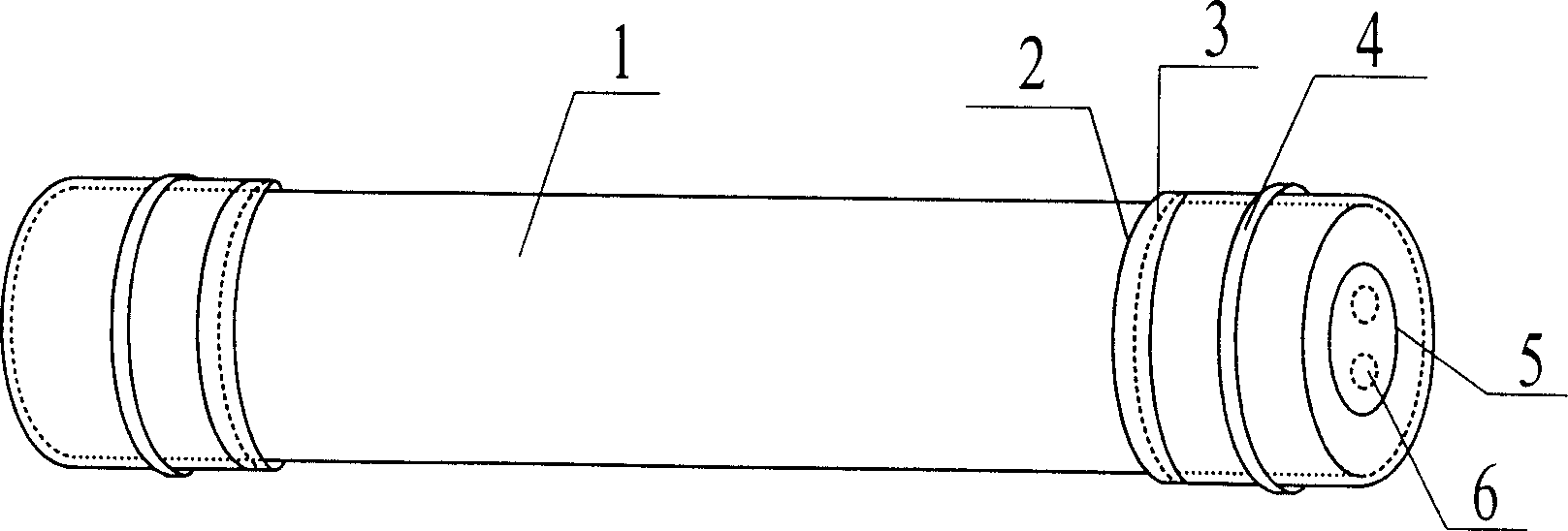

Cable protection and guide device

To provide a cable or the like protection and guide device that does not disperse dust particles such as wear particles generated by slide or friction between a cable or the like and link frame bodies. A number of link frame bodies ( 11 ) articulably connected to each other in the longitudinal direction of the device in a state where a cable or the like ( 14 ) are accommodated and hermetically sealed, each comprise a pair of link plate ( 23 ) disposed on both sides of the cable or the like, and connecting rods ( 22, 24 ) bridged across the link plates on the bend outer peripheral side and on the bend inner peripheral side, respectively. Between at least the bend outer peripheral side of the link plate and the connecting rod ( 24 ) bridged on the bend outer peripheral side is openably provided a sealing structure by concave and convex fitting ( 48, 49, 148, 149, 148, 149 ). Thus, the respective frame bodies are reliably hermetically sealed by the connecting rods ( 24 ) and dust particles present in the inside space of the link frame bodies through which the cable or the like is penetrated are not dispersed outside.

Owner:TSUBAKIMOTO CHAIN CO

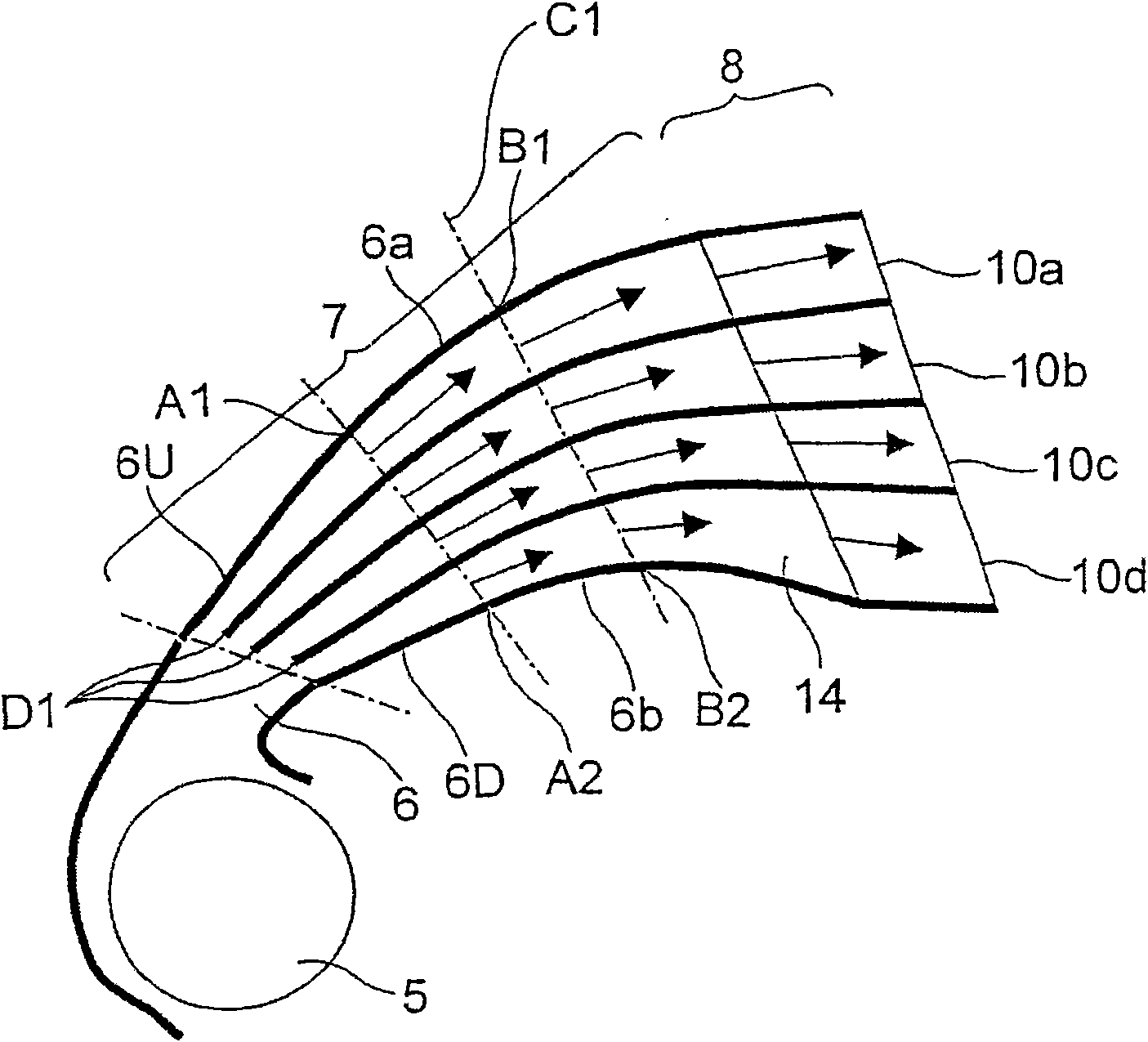

Micro-particle diffusing device

ActiveCN101658688BPrevent proliferationGood effectLighting and heating apparatusGaseous substancesDiffusionEngineering

The invention provides a micro-particle diffusing device. The micro-particle diffusing device is provided with first discharge openings (10a-10c) for discharging first airflows to the upper part of anindoor living space, a second discharge opening (10d) provided below the first discharge openings (10a-10c) and discharging a second airflow to below the first airflows, and a micro-particle generating device (17) for generating micro-particles. The micro-particles generated by the micro-particle generating device (17) are discharged indoors, and the concentration of micro-particles discharged from the first discharge openings (10a-10c) is set lower than the concentration of micro-particles discharged from the second discharge opening (10d). So that the first airflows become an atmosphere screen, for preventing the diffusion of the micro-particles contained in the second airflows to the upper space of the living space. Therefore, a great deal micro-particles generated by the micro-particle generating device to the living space, to obtain better sterilizing, relaxing or the like effects.

Owner:SHARP KK

A method of making a photodiode

Owner:WUHAN TELECOMM DEVICES

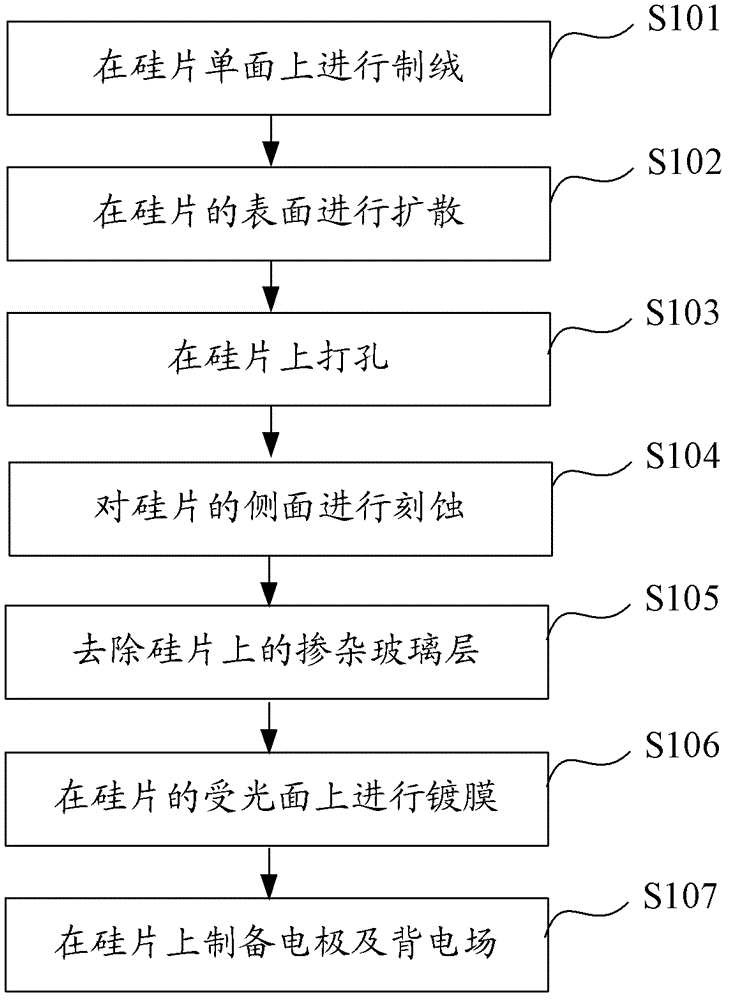

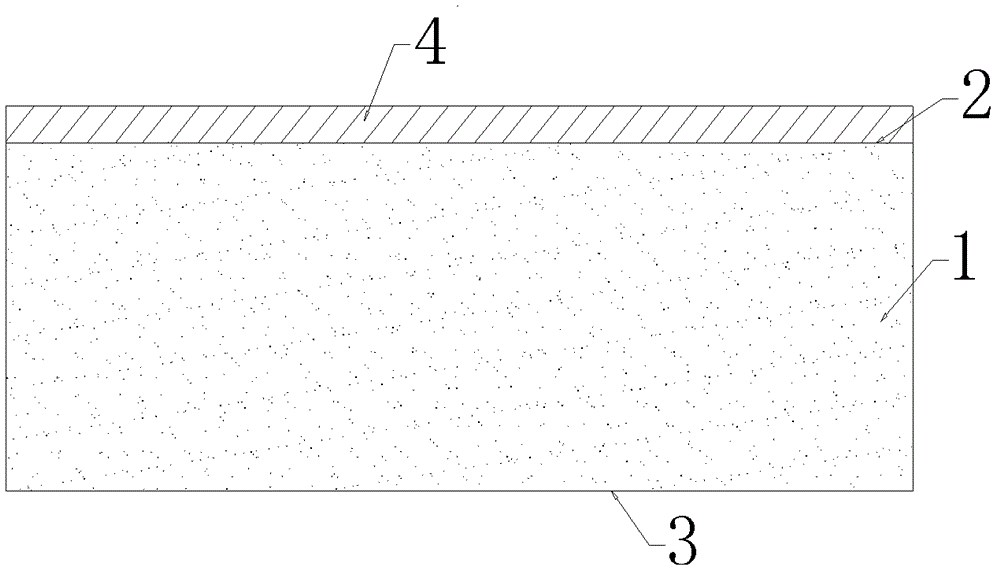

Manufacturing method for back contact crystalline silicon solar cell

InactiveCN102800744ADiffusion will notReduce the risk of electric leakageFinal product manufacturePhotovoltaic energy generationIsolation proceduresFragmentation rate

The invention discloses a manufacturing method for a back contact crystalline silicon solar cell. The manufacturing method comprises the following steps of: performing texturing and diffusion on the surface of a semiconductor substrate; reserving through holes in the semiconductor substrate after the diffusion; etching the semiconductor substrate with the through holes; removing a doped glass layer from the etched semiconductor substrate; coating a film on the illuminated surface of the semiconductor substrate from which the doped glass layer is removed; and preparing electrodes and a back surface field on the film-coated semiconductor substrate to obtain the back contact crystalline silicon solar cell. According to the method, the surface of the semiconductor substrate is diffused, and the through holes are reserved in the semiconductor substrate after the diffusion, so that the inner walls of the through holes cannot be diffused, namely emitter junctions in the through holes are avoided. Compared with the prior art, the method has the advantages of eliminating a laser isolation procedure, reducing the electric leakage risks of the cell and greatly lowering the fragmentation rate of the cell. In addition, the laser isolation procedure is eliminated, so that a process is simple, equipment cost is reduced, and industrial production is facilitated.

Owner:CSI CELLS CO LTD

A low-temperature cutting method and device suitable for hit batteries

ActiveCN110788483BReduce performanceReduce depositionLaser beam welding apparatusLaser processingEngineering

Owner:上海润势科技有限公司

Novel sanitary appliance exhaust system for toilet

InactiveCN112575858ADischarge in timeEfficient dischargeDispersed particle filtrationLavatory sanitoryBackflow prevention deviceMechanical engineering

The invention provides a novel sanitary appliance exhaust system for a toilet, which can timely and effectively exhaust peculiar smell out of the toilet and prevent the peculiar smell from diffusing.The air exhaust system comprises a urinal, a first air exhaust pipeline, a gas backflow prevention device, a first exhaust device, a second exhaust device, a second exhaust pipeline, an air supply device and a third exhaust pipeline. The first exhaust pipeline is connected with the urinal, the gas backflow prevention device and the first exhaust device are both arranged in the first exhaust pipeline, the second exhaust pipeline is connected with the second exhaust device, an air inlet of the third exhaust pipeline is opposite to the air supply device, and the third exhaust pipeline is communicated with the second exhaust pipeline. In the embodiment, through combination of the first exhaust device, the second exhaust device and the air supply device, through the air suction of the first exhaust device connected with the urinal, air supply of the air supply device located on the lower portion and air suction of the second exhaust device located on the top, peculiar smell gas and pollutant particles can be effectively exhausted out of a toilet in time, and therefore the purpose of saving energy is achieved and will not be diffused anywhere .

Owner:SOUTHEAST UNIV

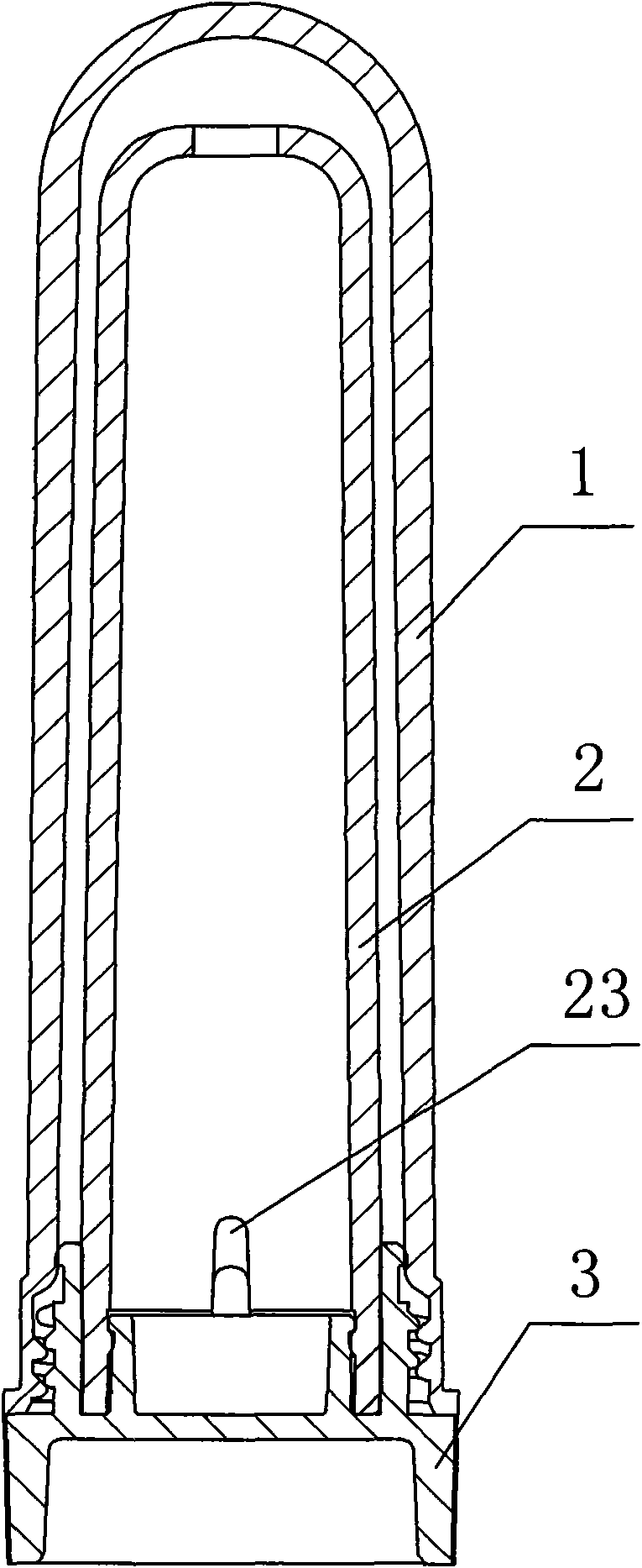

Aromatic nose device

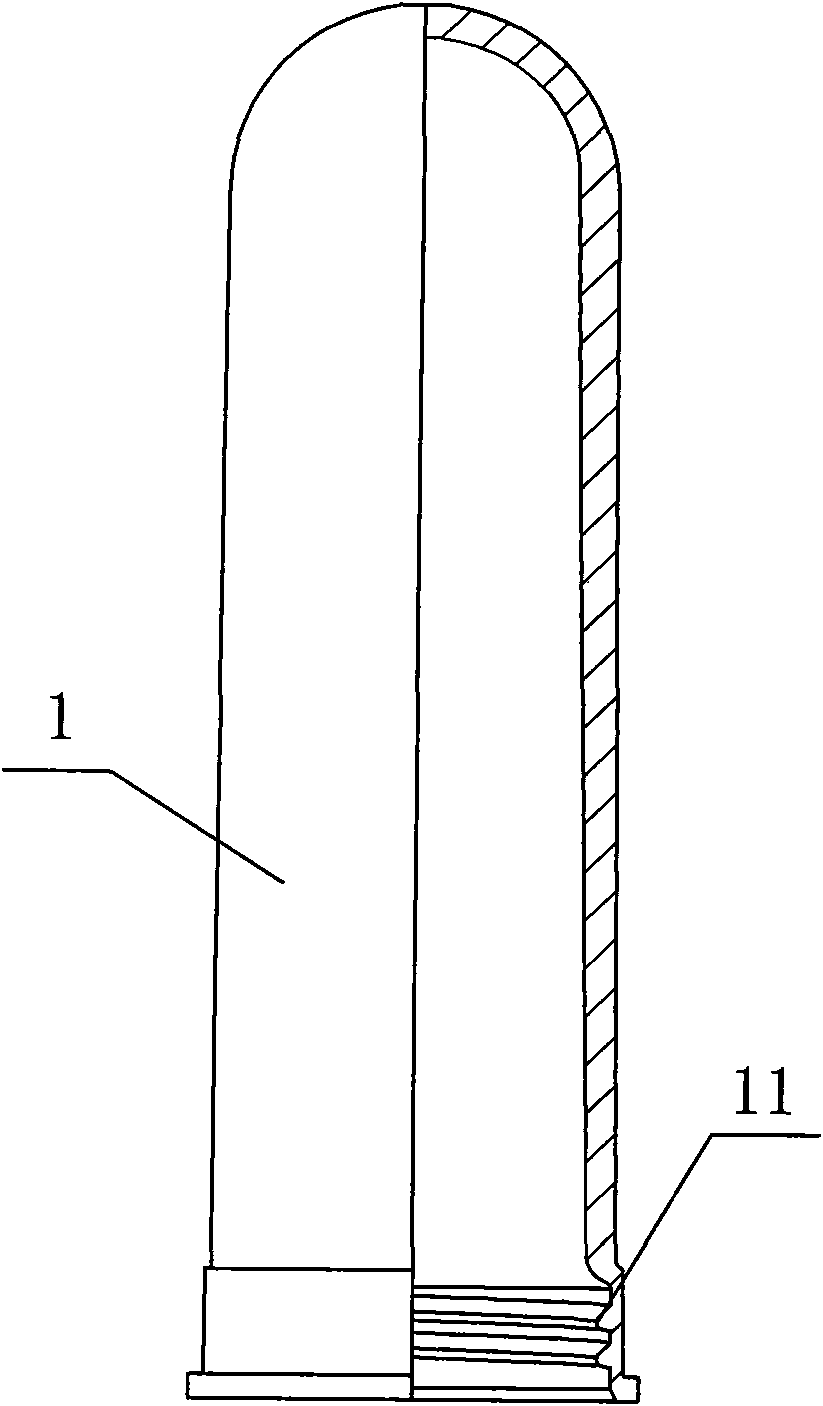

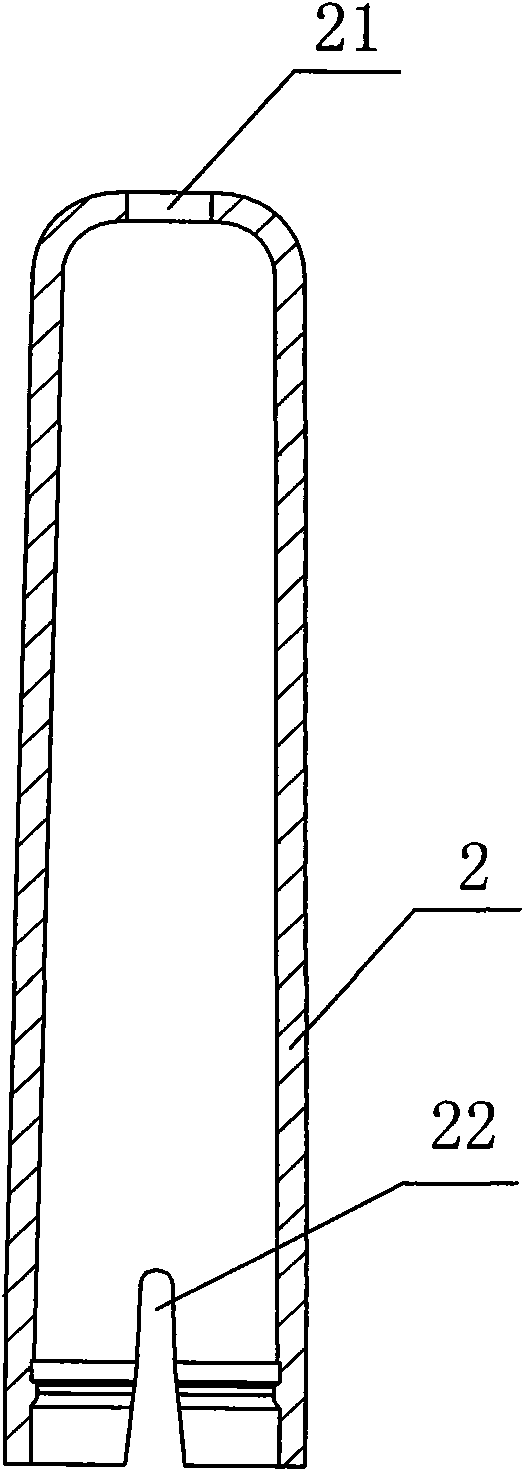

InactiveCN101642596AGuaranteed cleanlinessClean thoroughlyGaseous substancesInhalatorsNoseEngineering

The invention discloses an aromatic nose device comprising a shell (1), an aromatic source container (2) and a base (3), wherein the hollow aromatic source container (2) with an open end is arranged in the shell (1); at least one ventilating hole (21) is arranged on the surrounding surface of the hollow aromatic source container (2); the open end and the base (3) are movably connected and the shell (1) and the base (3) are in threaded connection or clamping connection. When the aromatic nose device is used, the shell (1) is turned on and a smell source outwards diffuses from the ventilating hole (21) of the aromatic source container (2), thereby achieving the purpose for bringing aroma, preventing diseases, treating the diseases or lifting spirit; when the aromatic nose device is not used,the shell (1) is turned off for preventing the smell source from outwards diffusing, thereby the aromatic nose device has the advantages of convenient use and portability and repeated use.

Owner:FOSHAN SOUTHERN PACKAGING

A special drawing paper for gouache painting

ActiveCN108589392BStrong toughnessImprove toughnessNon-fibrous pulp additionSpecial paperPolymer scienceAdhesive

Owner:XINXIANG UNIV

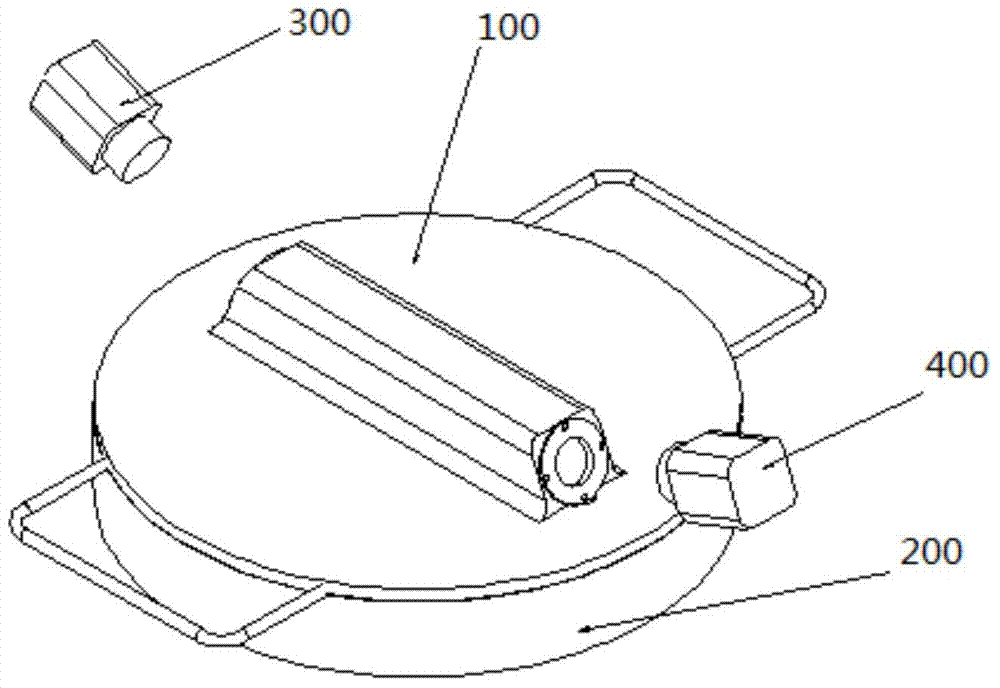

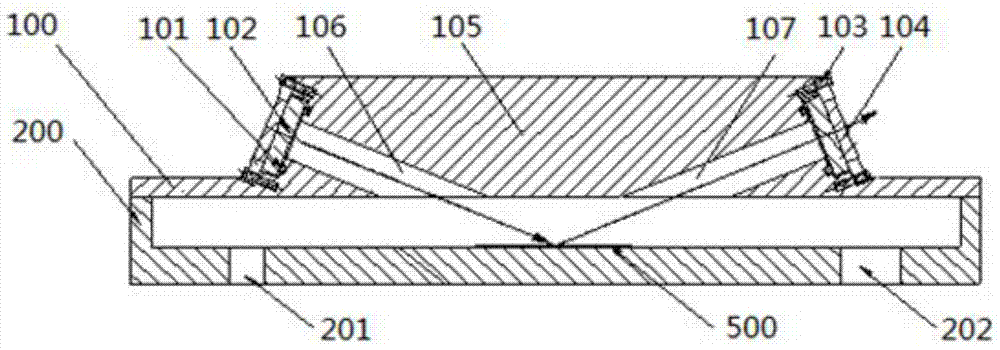

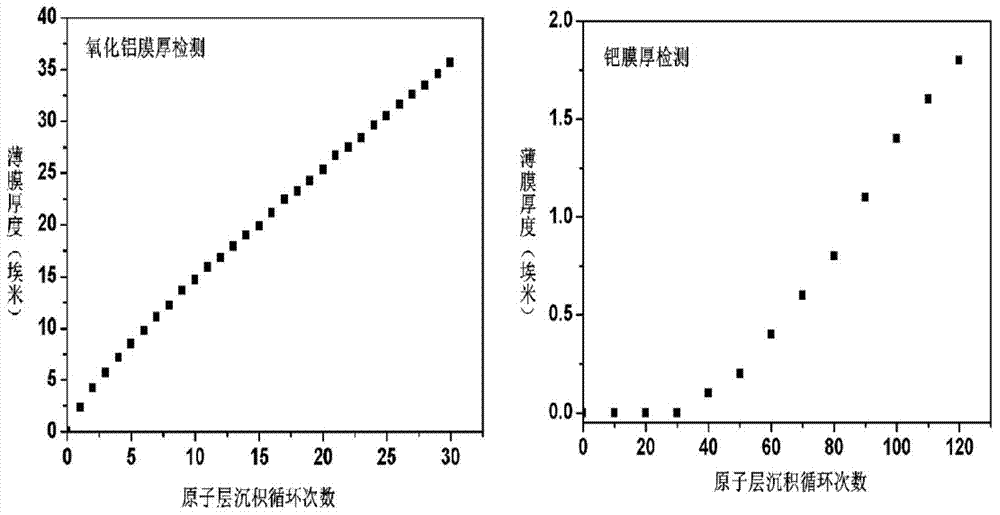

In situ elliptical polarization measurement device

ActiveCN103674252BMonitor Growth ChangesDiffusion will notUsing optical meansLight polarisation measurementMeasurement deviceStructure of the Earth

An in situ elliptical polarization measurement device comprises a sealing cover (100); an incidence hole (106) and a reflection hole (107) which respectively allow incidence and reflection of a polarized light are arranged on the sealing cover; an incidence light penetration mouth (108) and a reflection light penetration mouth (109) which are sealed are respectively arranged at outer openings of the incidence hole and the reflection hole; while a thin film reaction cavity is maintained closed, a thin film thickness can be measured at any moment in an atomic layer deposition process; an opening within a cavity of an optical path hole, and air inlet and outlet mouths of a reaction cavity are staggered, so that an air flow in the reaction cavity is not easy to enter the optical path hole and a reagent is prevented from depositing on an inner wall of the optical path hole; the complex regular cleaning is not needed; and the whole measuring device is simple and compact in structure, and easy to use.

Owner:HUAZHONG UNIV OF SCI & TECH

White ant fumigating treating method for log

InactiveCN1227973CImprove adhesionPrevent leakageInsect catchers and killersPolyvinyl chlorideEngineering

A fumigating method for killing the termite in timber includes such steps as adhering the PVC films to both ends of a timber for sealing them, binding the PVC film on the surface of said timber for preventing air leakage, and injecting the fumigant (sulfuryl chloride or methyl bromide) into said timber by use of PQF-I injector. Its advantage is high effect.

Owner:PLANT & FOOD INSPECTION & QUARANTINE TECHN CENT SHENZHEN BUREAU FOR ENTRY & EXIT INSPECTION & QUARANTINE

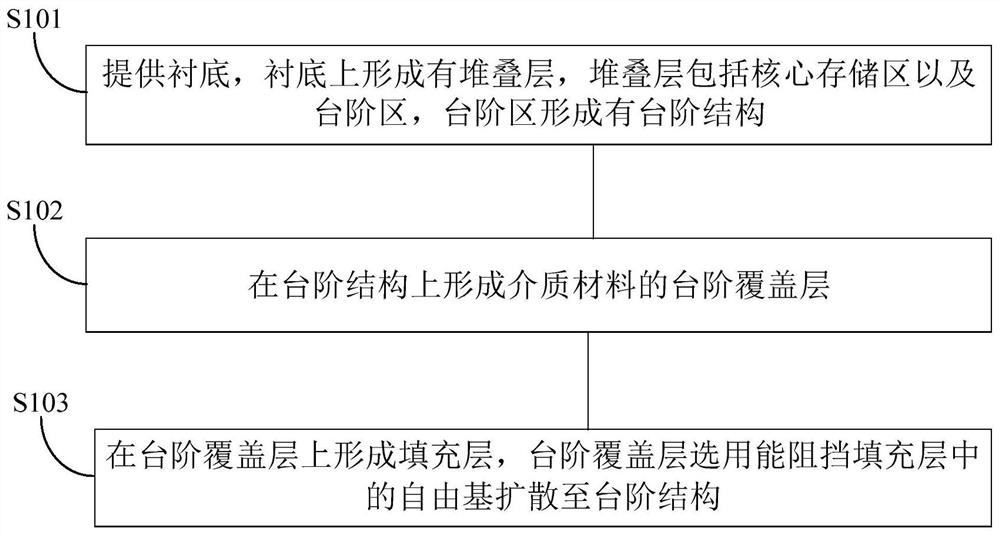

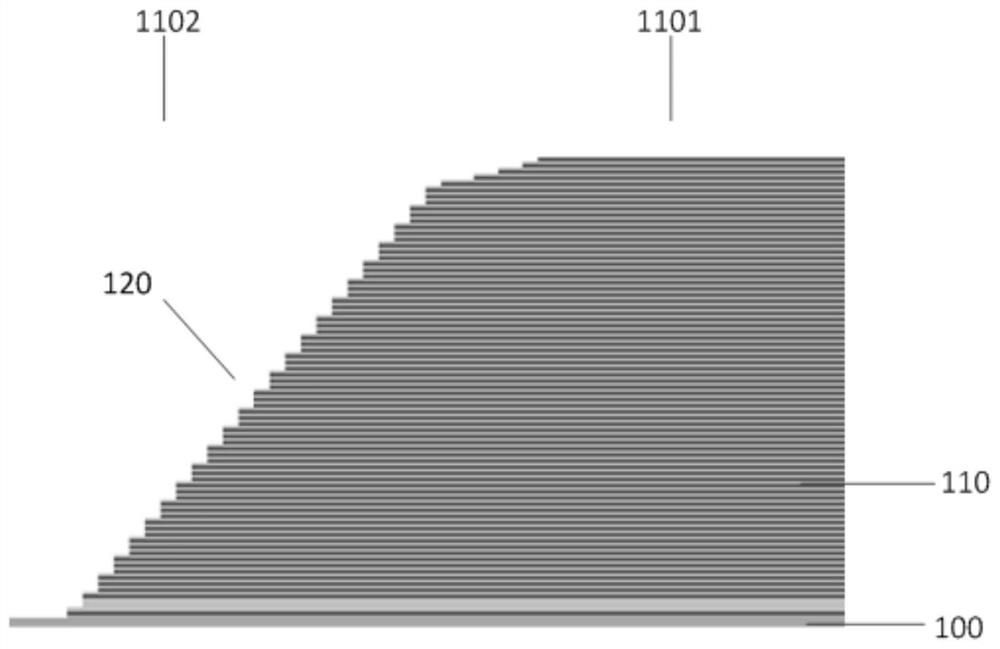

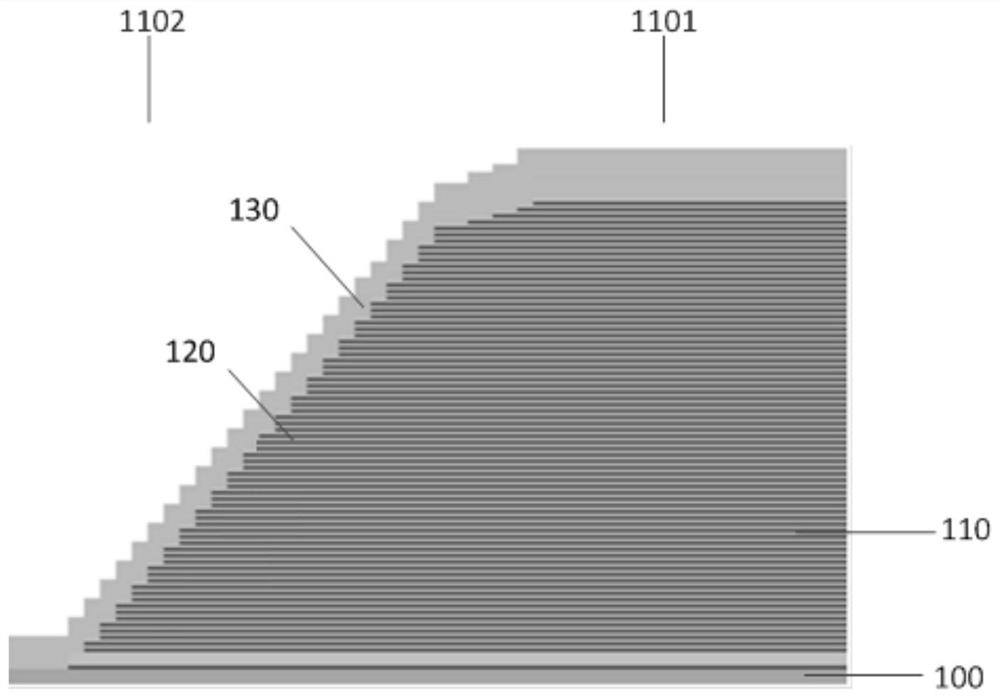

3D NAND memory device and manufacturing method thereof

PendingCN113113418AImprove performanceDiffusion will notSolid-state devicesSemiconductor devicesEngineeringStructural engineering

The invention provides a 3D NAND memory device and a manufacturing method thereof. The method comprises the steps of after a step structure is formed, at least forming a step covering layer on the step structure, then at least forming a filling layer on the step covering layer, wherein the step covering layer is made of a material capable of preventing free radicals in the filling layer from diffusing to a stacking layer, so that a barrier layer of free radicals can be formed between the filling layer and the step structure, and even if free radicals of H roots and OH roots exist in the filling layer, the released free radicals of the H roots and OH roots can be blocked by the step covering layer and cannot diffuse into the step structure, and accordingly the step structure cannot be eroded, the step structure is protected, and the device performance is improved.

Owner:YANGTZE MEMORY TECH CO LTD

Foldable sound insulation shed for urban landscape dam

PendingCN112627598AGuarantee flood discharge capacityAffect production and lifeSpecial buildingSound proofingChain linkUrban landscape

The invention provides a foldable sound insulation shed for an urban landscape dam, and relates to a sound insulation device, and particularly relates to a sound insulation shed. The foldable sound insulation shed comprises a sound insulation main body top layer, sound insulation walls, sound insulation wall underground foundations, sound insulation wall sliding wheels, motors, transmission chains, second transmission chains and sound insulation wall sliding auxiliary wheel guide rails, wherein the sound insulation walls are arranged on the two sides of the sound insulation main body top layer; the sound insulation wall underground foundations are arranged below the sound insulation walls; the guide rails are laid on the sound insulation wall underground foundations; the sound insulation wall sliding wheels are connected with the guide rails and the sound insulation walls; the motors are arranged on the sound insulation wall underground foundations and are positioned on the outer sides of the sound insulation walls; the sound insulation wall sliding wheels are connected with the motors through the transmission chains; the sound insulation wall sliding auxiliary wheels are arranged on the outer end faces of the sound insulation wall sliding wheels; and the second transmission chains are used for connecting the sound insulation wall sliding auxiliary wheels with other sliding auxiliary wheels positioned in the same horizontal direction. The foldable sound insulation shed has the characteristics of high sound insulation performance, high strength, light dead weight, high rigidity, foldability and the like.

Owner:福建水利电力职业技术学院

Moldproof antistaling coating as well as preparation method and application thereof

InactiveCN108084817AImprove barrier propertiesGood chemical stabilityAntifouling/underwater paintsPaints with biocidesWater vaporDissolution

The invention relates to a mold-proof antistaling coating as well as a preparation method and application thereof. The mold-proof antistaling coating is prepared from the following raw materials in parts by mass: 60 to 65 parts of resin, 5 to 10 parts of a mold-proof agent, 30 to 35 parts of a solvent and 0.3 to 2 parts of an assistant, wherein the resin is prepared from the following components in percentage by mass: 28 to 32 percent of ethylene-vinyl acetate copolymer, 36 to 40 percent of polyvinylidine chloride, 12 to 15 percent of ethylene-vinyl alcohol copolymer, 10 to 12 percent of acrylate copolymer with a core-shell structure and 4 to 6 percent of polyurethane with an IPN structure. The mold-proof antistaling coating has the advantages that adsorption and dissolution of water vapormolecules can be restricted to the maximum extent, and external water is effectively prevented from entering the insides of packaging materials so as to inhibit mold; meanwhile, the water vapor molecules inside the packaging materials are also prevented from being diffused to the outside, and the constant moisture inside the packaging materials is kept, so that the effects of retaining freshnessand moisturizing are realized. The mold-proof agent is exposed to the surface of the coating in an embedded manner; after the mold-proof agent is contacted with microorganisms, the microorganisms aredestroyed or prevented from sprouting, so that the aim of preventing microbial growth is achieved.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com