Manufacturing method of photo diodes

A technology of photodiodes and manufacturing methods, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of insufficient response of photodiodes and achieve the effect of improving the responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

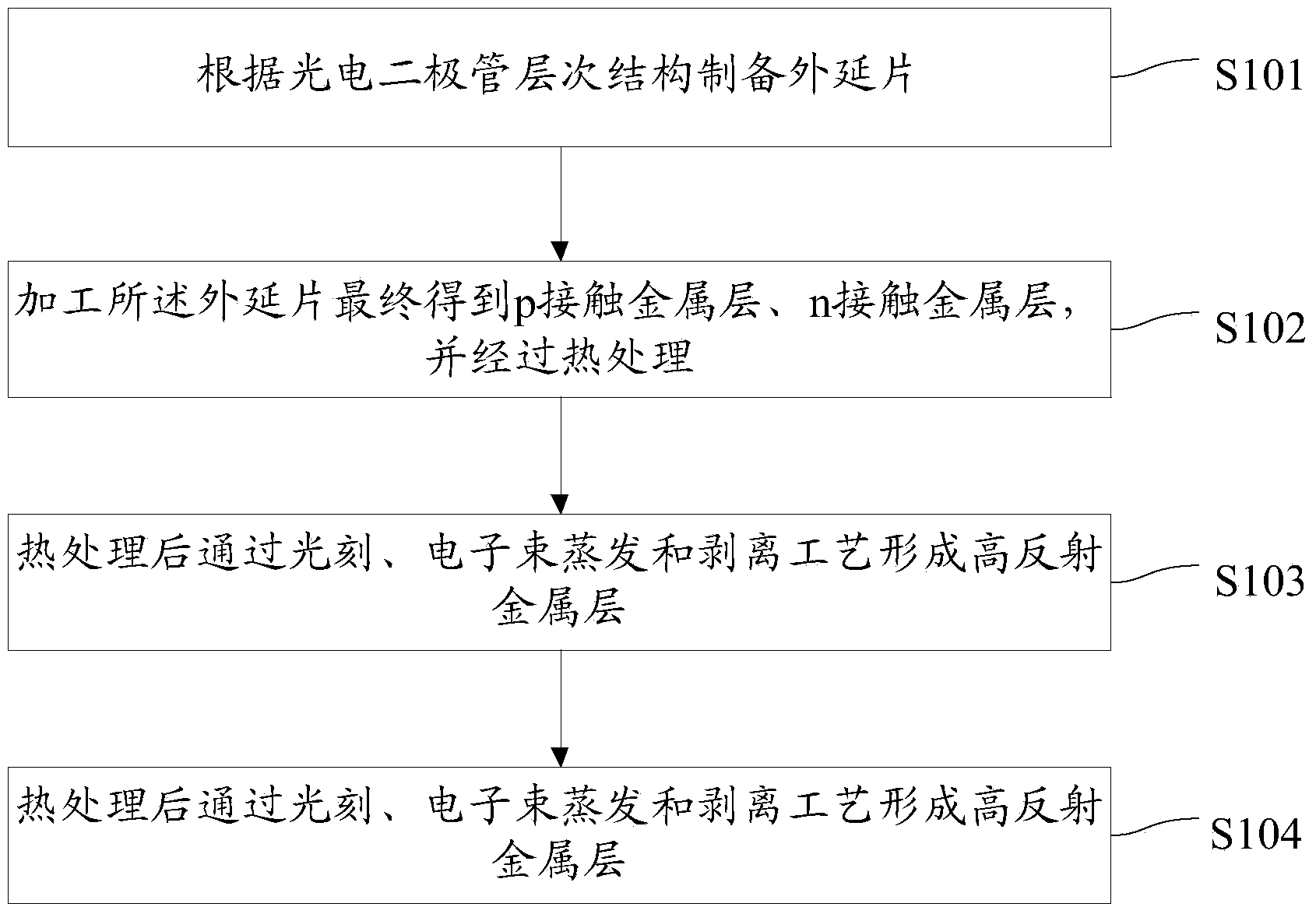

[0020] figure 1 The process flow of the method for manufacturing a photodiode provided by the embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0021] The fabrication method of the photodiode provided in this embodiment comprises the following steps:

[0022] Step S101 , preparing an epitaxial wafer according to the hierarchical structure of the photodiode.

[0023] Different photodiodes may have epitaxial wafer structures with different levels. Generally, the metal organic chemical vapor deposition method is used to sequentially grow each layer on the InP substrate, and finally the epitaxial wafer is obtained.

[0024] Step S102 , processing the epitaxial wafer to finally obtain a p-contact metal layer and an n-contact metal layer, and undergo heat treatment.

[0025] The specific manufacturing process may be different for different photodiodes, but they all include...

Embodiment 2

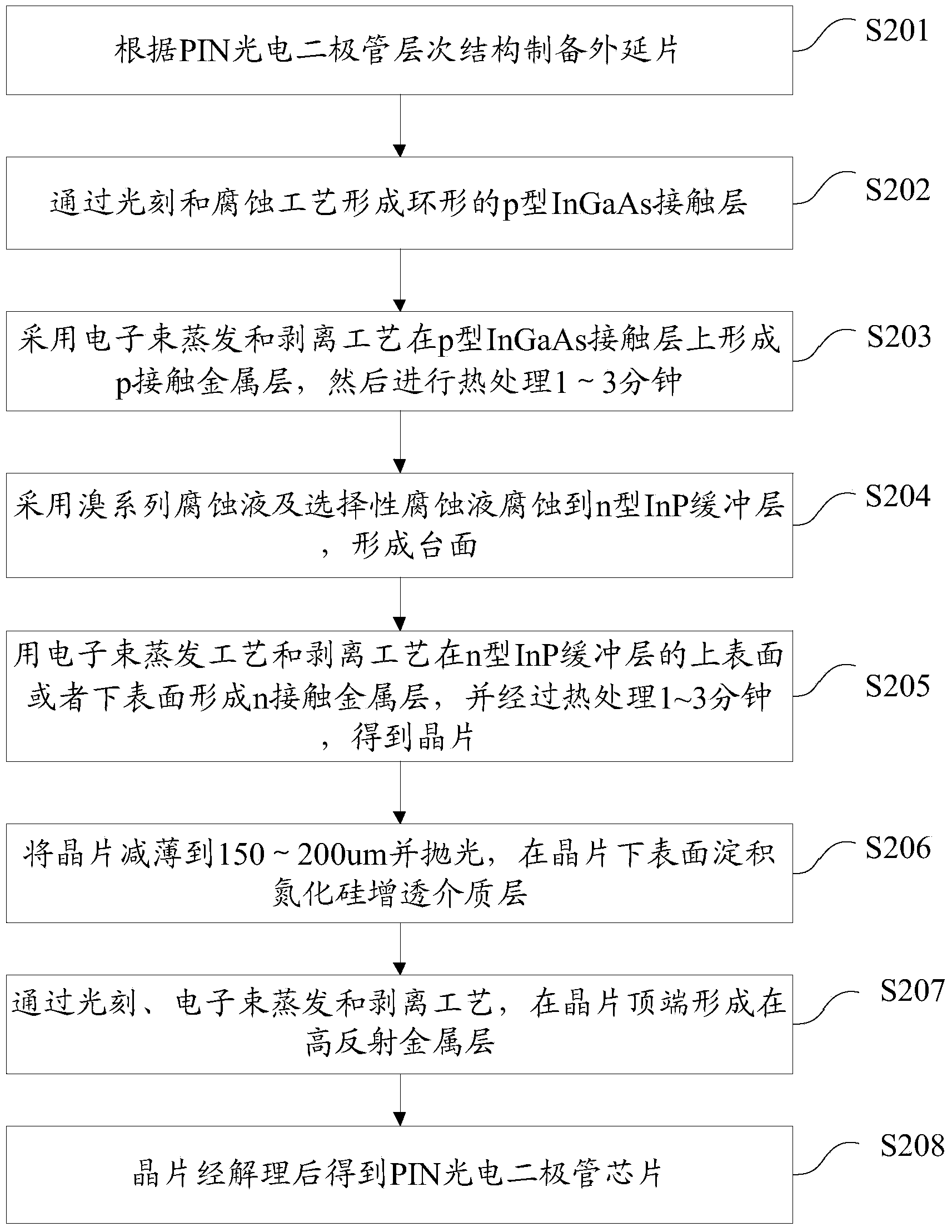

[0030] figure 2 The process flow of the method for manufacturing a photodiode provided by the embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0031] In this embodiment, a PIN photodiode is taken as an example to specifically describe the method for fabricating the photodiode. Such as figure 2 shown, including the following steps:

[0032] Step S201 , preparing an epitaxial wafer according to the hierarchical structure of the PIN photodiode.

[0033] The PIN photodiode is produced by etching the epitaxial wafer. The epitaxial wafer of the PIN photodiode includes an n-type InP substrate at the bottom layer. Each layer is sequentially grown on the InP substrate by metal organic chemical vapor deposition, including the n-type InP buffer. layer, n-type InGaAs light absorbing layer, p-type InP window layer, p-type InGaAs contact layer. As an implementation manner, th...

Embodiment 3

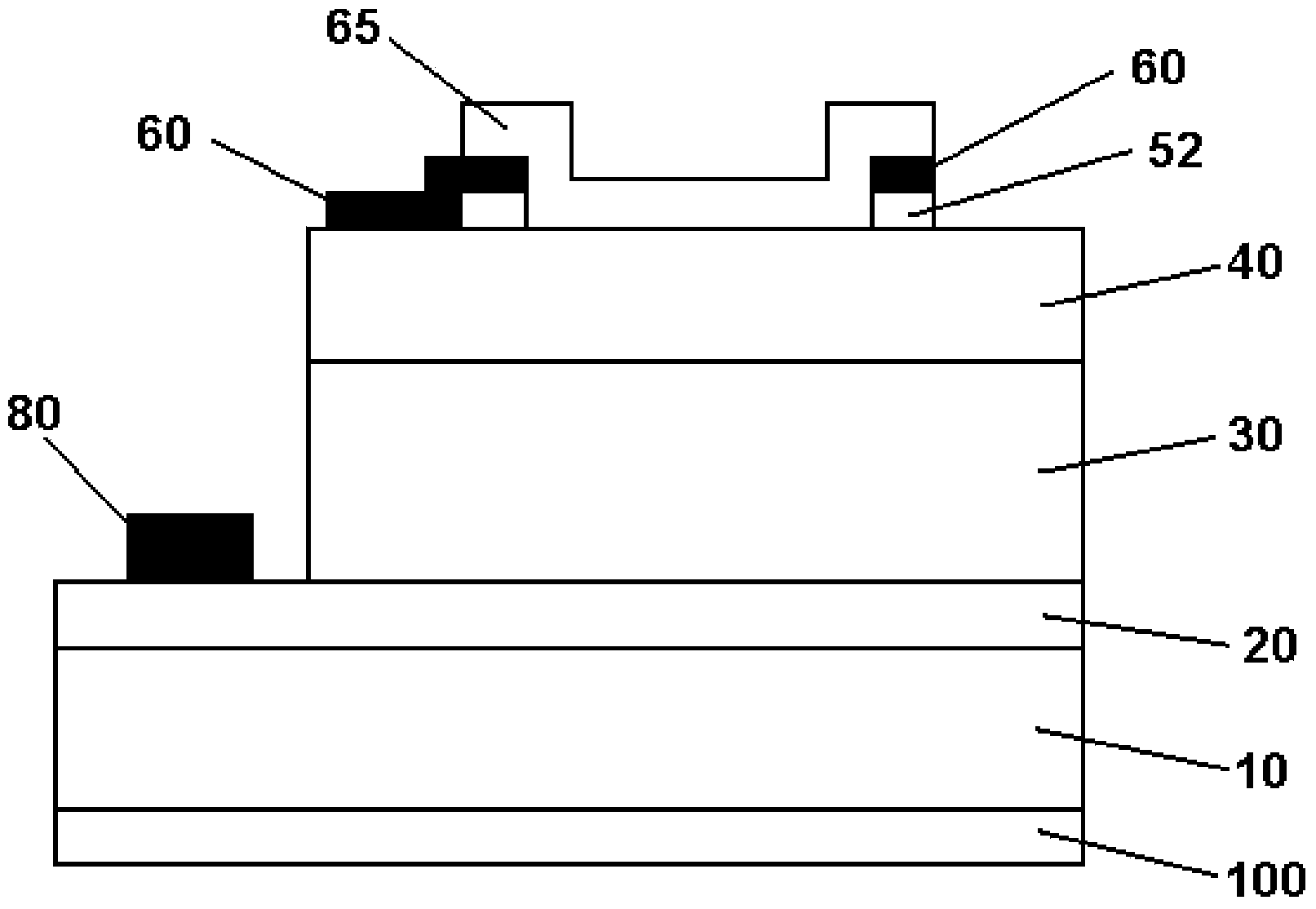

[0050] Figure 5 The process flow of the method for manufacturing a photodiode provided by the embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0051] In this embodiment, an avalanche photodiode is taken as an example to specifically describe the method for fabricating the photodiode. Such as Figure 5 shown, including the following steps:

[0052] Step S501 , preparing an epitaxial wafer according to the hierarchical structure of the avalanche photodiode.

[0053] The avalanche photodiode is produced by etching the epitaxial wafer. The epitaxial wafer of the avalanche photodiode includes an n-type InP substrate at the bottom layer. Various layers are sequentially grown on the InP substrate by metal organic chemical vapor deposition, including n-type InP buffer layer, n-type InGaAs light absorption layer, n-type InP electric field control layer, n-type InP window l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com