Method for diffusing multi-element heavy rare earth on sintered neodymium-iron-boron magnet grain boundary

A technology of grain boundary diffusion and heavy rare earth, applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve the problems of high manufacturing cost, inability to adjust at will, increase the manufacturing cost of NdFeB magnets, etc., and meet the requirements of reducing the target material. The effect of avoiding cost increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

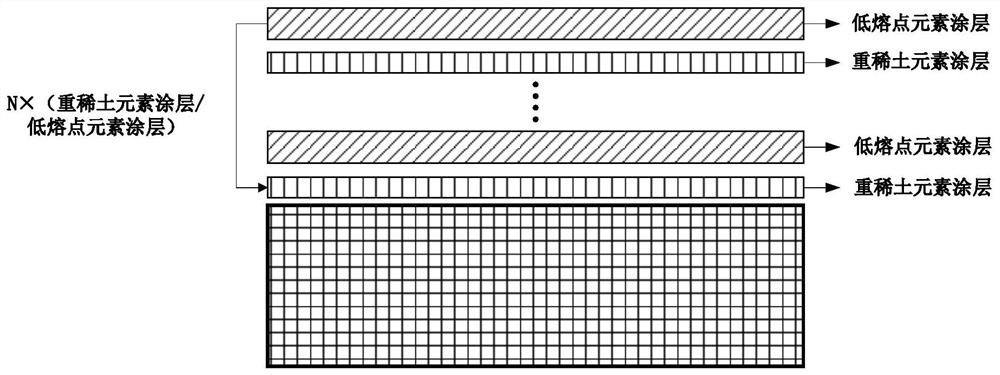

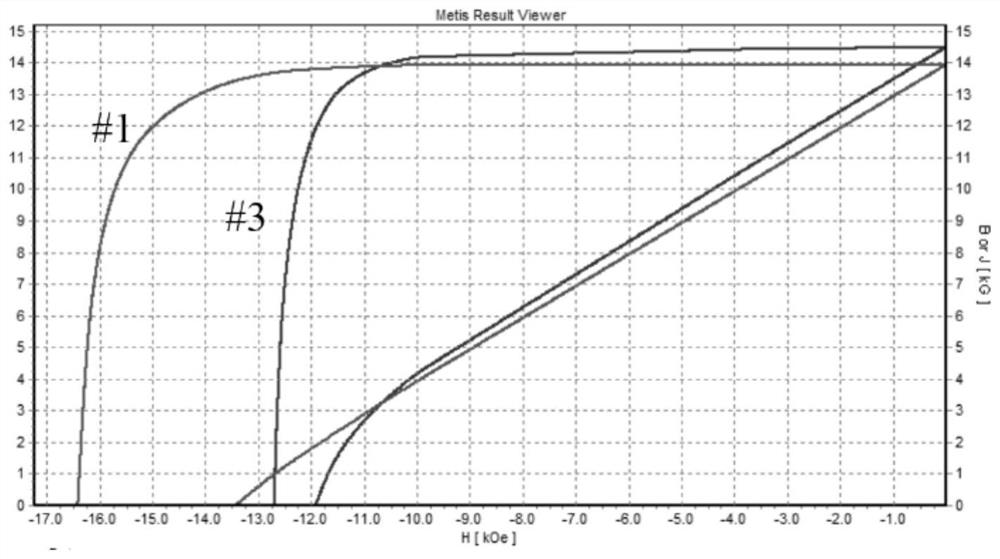

[0057] In this embodiment, the sintered NdFeB magnet #1 whose brand is 52N is used, and its size is 25mm*25mm*3mm. Dy is selected as the heavy rare earth element target, and Al is selected as the low melting point element target. The heavy rare earth Dy coating and the low melting point Al coating were sequentially deposited on the surface of 25mm*25mm by magnetron sputtering, followed by vacuum heat treatment.

[0058] The specific process is as follows:

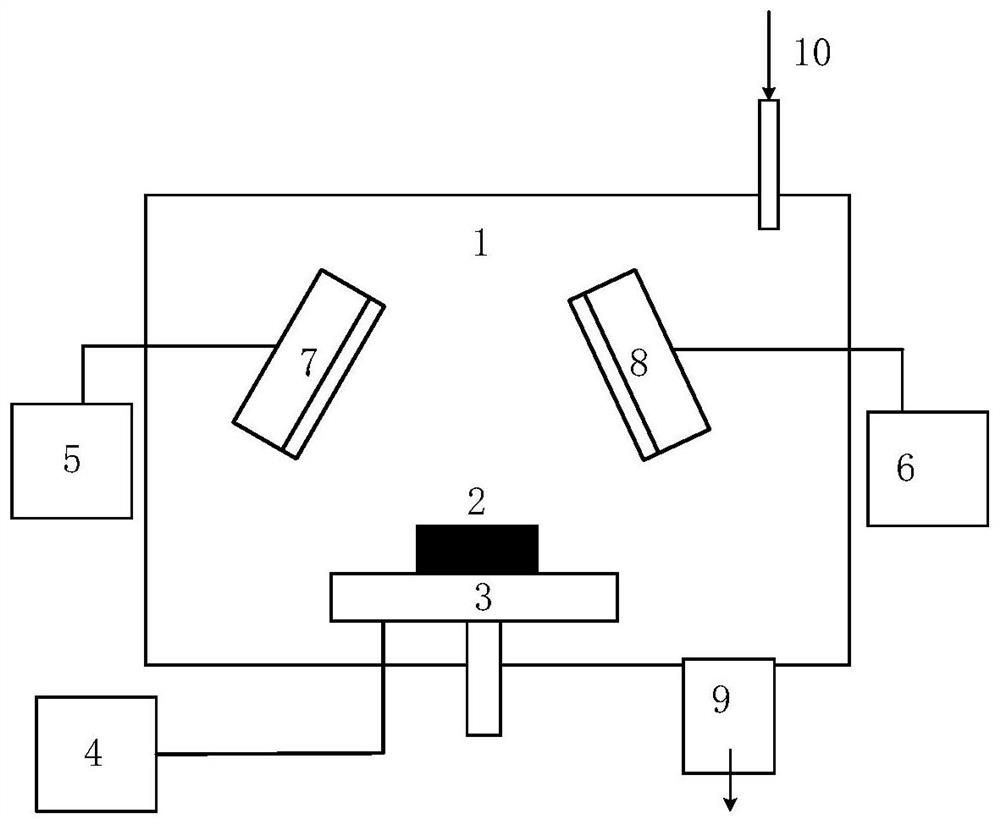

[0059] The first step is to clean the surface of the sintered NdFeB magnet. The surface of the NdFeB magnet was ground, ultrasonically cleaned and dried in sequence; then the NdFeB magnet was placed on the workpiece frame of the coating preparation device, and the vacuum cavity was pumped to 5×10 by the vacuum obtaining system. -3 Pa. The Ar gas is introduced into the vacuum chamber and the Ar gas flow rate is adjusted so that the vacuum degree reaches 2Pa. Use a bias power supply to negatively bias the workpiece holder...

Embodiment 2

[0073] In this embodiment, the sintered NdFeB magnet #4 whose brand is 52N is used, and its size is 25mm*25mm*3mm. Dy is selected as the heavy rare earth element target, and Al is selected as the low melting point element target. Magnetron sputtering is used to sequentially deposit heavy rare earth Dy coating / low melting point Al coating on its 25mm*25mm surface, followed by vacuum heat treatment.

[0074] The specific process is as follows:

[0075] The first step: cleaning the surface of the sintered NdFeB magnet. Exactly the same as the first step in Example 1.

[0076] The second step: heavy rare earth Dy coating deposition. Exactly the same as the second step in Example 1

[0077] The third step: low melting point Al coating deposition. It is exactly the same as the third step in Example 1, except that the deposition time is 4 minutes, and the thickness of the Dy coating is about 1.2 μm.

[0078] The fourth step: exactly the same as the fourth step in Example 1.

...

Embodiment 3

[0089] In this embodiment, the sintered NdFeB magnet #6 whose brand is 52N is used, and its size is 25mm*25mm*3mm. Dy is selected as the heavy rare earth element target, and Al is selected as the low melting point element target. Magnetron sputtering is used to sequentially deposit heavy rare earth Dy coating / low melting point Al coating / heavy rare earth Dy coating / low melting point Al coating on the surface of 25mm*25mm, followed by vacuum heat treatment.

[0090] The specific process is as follows:

[0091] The first step: cleaning the surface of the sintered NdFeB magnet. Exactly the same as the first step in Example 1.

[0092] The second step: heavy rare earth Dy coating deposition. Adjust the Ar gas flow rate so that the air pressure in the vacuum chamber is 0.7 Pa. Turn on the Dy target magnetron magnetron sputtering source, and load the negative bias voltage on the NdFeB magnet to complete the deposition of the Dy coating on the surface of the NdFeB magnet. Among ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com