Moldproof antistaling coating as well as preparation method and application thereof

A coating and anti-mildew technology, applied in anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of poor preservation performance of anti-mildew plastic wrap, oxidative decay of fresh food, loss of original value, etc. , to achieve excellent fresh-keeping effect, good anti-mildew effect, and the effect of preventing microbial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

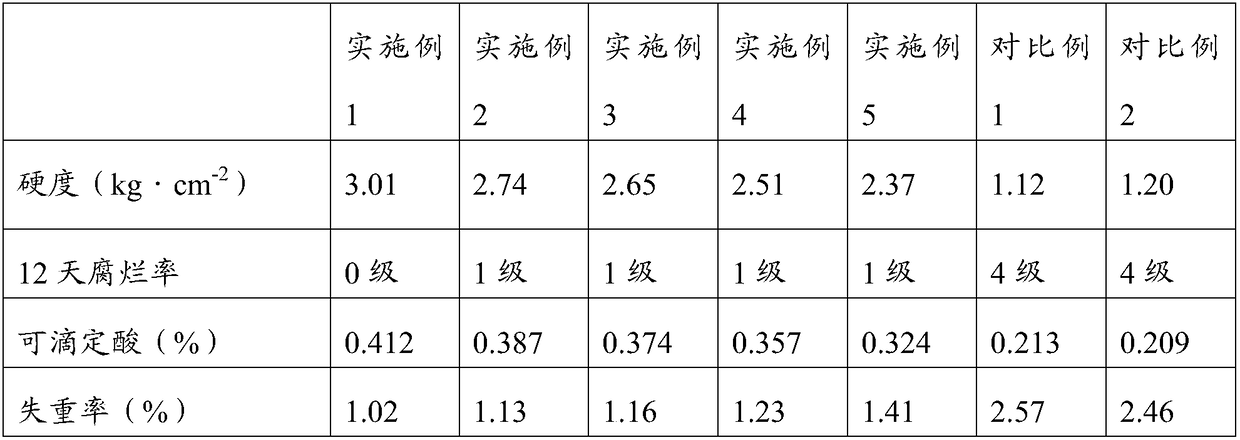

Examples

preparation example Construction

[0028] The method for preparing the above mildew-proof and fresh-keeping coating according to an embodiment of the present invention comprises the following steps S1-S3:

[0029] S1. Weigh each raw material according to the parts by mass.

[0030] S2. Put the resin and solvent into the reaction kettle, heat up to 40-60° C. and stir at 600-1000 rpm for 1-2 hours.

[0031] S3. Put the remaining raw materials into the reaction kettle, and continue stirring at 800-1200 rpm for 1-2 hours to obtain the anti-mold and fresh-keeping coating.

[0032] The preparation method of the above-mentioned mildew-proof and fresh-keeping coating is simple in process and easy to realize. The obtained mildew-proof and fresh-keeping coating is coated on the surface of the film and after the water evaporates to form a coating, it can limit the adsorption and dissolution of water vapor molecules to the greatest extent, and the intermolecular The strong cohesion can inhibit the movement of liquid molec...

Embodiment 1

[0036]Weigh each raw material according to the following parts by mass: 62 parts of resin, 5 parts of sodium diacetate, 1 part of arbutin, 1 part of thymol, 2 parts of Houttuynia cordata injection, 2 parts of astragalin, 2 parts of quercetin 0.4 parts, 1 part of soybean isoflavone, 0.8 parts of spermidine trihydrochloride, 0.2 parts of rutin, 0.8 parts of chlorogenic acid, 32 parts of water, 0.5 parts of surfactant, 0.5 parts of leveling agent and 0.5 parts of dispersant. Among them, the resin is composed of the following components by mass percentage: 32% ethylene-vinyl acetate copolymer, 38% polyvinylidene chloride, 14% ethylene-vinyl alcohol copolymer, 12% core-shell structure acrylate copolymer and 4% IPN structural polyurethane. Put the resin and water into the reaction kettle, heat the reaction kettle to 50° C., turn on the stirring device, and stir at 600 rpm for 1 hour. Then put the remaining raw materials into the reaction kettle, and continue to stir at 1000 rpm for...

Embodiment 2

[0038] The experimental procedure of Example 2 is basically the same as that of Example 1, except that the raw materials do not include ascarin and quercetin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com