A laser processing analysis device and method with self-learning function

A laser processing and self-learning technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve problems such as poor self-adaptability, complicated adjustment process, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

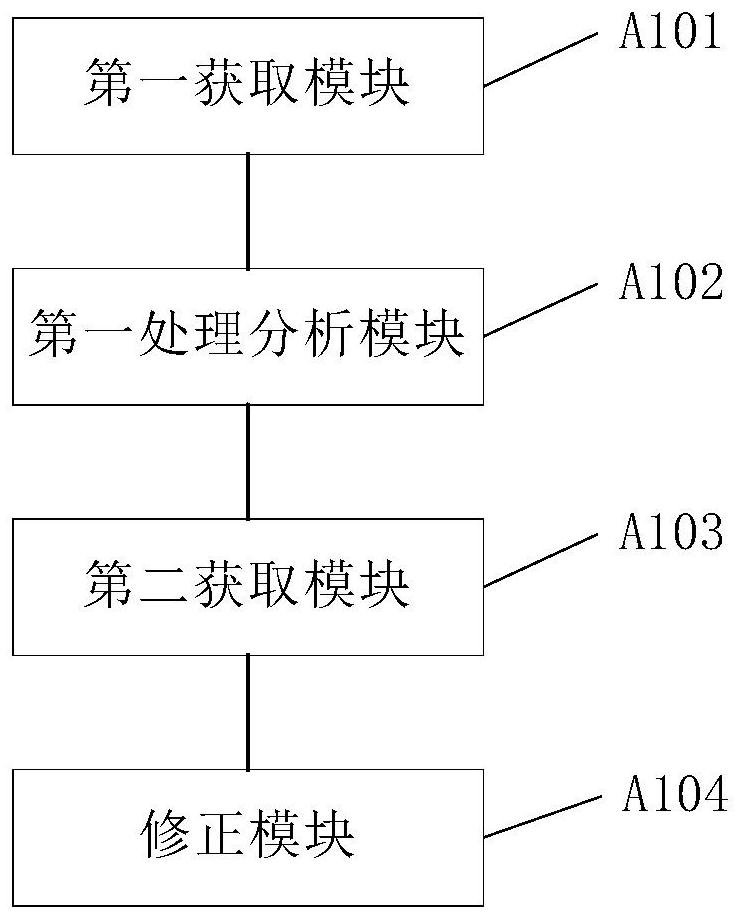

[0046] like figure 1 As shown, a kind of laser processing analysis device with self-learning function of an embodiment of the present invention is provided, including:

[0047] The first acquisition module A101 is used to acquire the processing information input by the user. The processing information includes the name of the target workpiece, the names of each part of the target workpiece, the thickness of each part of the target workpiece, the processing method of each part of the target workpiece, and the thickness of each part of the target workpiece. Processing speed, processing accuracy of the target workpiece and processing quality corresponding to each processing method of the target workpiece (such as heat-affected zone size, taper, etc.), the target workpiece is the workpiece to be processed, and the processing speed is the speed of laser processing the target workpiece;

[0048] The first acquisition module A101 also acquires processing data by recognizing voice or ...

Embodiment 2

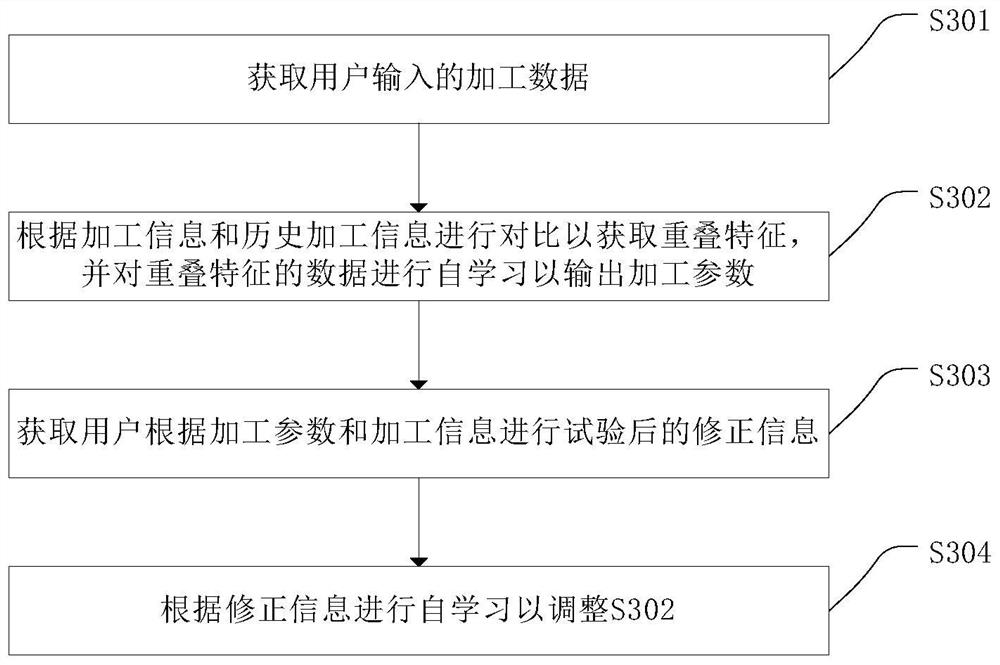

[0066] like image 3 As shown, a kind of laser processing analysis method with self-learning function of an embodiment of the present invention is provided, comprising the following steps:

[0067] S301 Obtain the processing information input by the user. The processing information includes the name of the target workpiece, the names of each part of the target workpiece, the thickness of each part of the target workpiece, the processing method of each part of the target workpiece, the processing speed of each part of the target workpiece, and the processing of the target workpiece. Accuracy and processing quality corresponding to each processing method of the target workpiece (such as heat-affected zone size, taper, etc.), the target workpiece is the workpiece to be processed, and the processing speed is the speed of laser processing the target workpiece.

[0068] The way of obtaining the processing information input by the user also includes obtaining the processing data by r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com