Simple recovery device of plastic bottle

A recycling device and a technology for plastic bottles, applied in the field of simple recycling devices for plastic bottles, can solve the problems of being unsuitable for small business production, occupying space for mineral water bottles, and slow in compression, and achieve the effects of low production cost, novel design and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

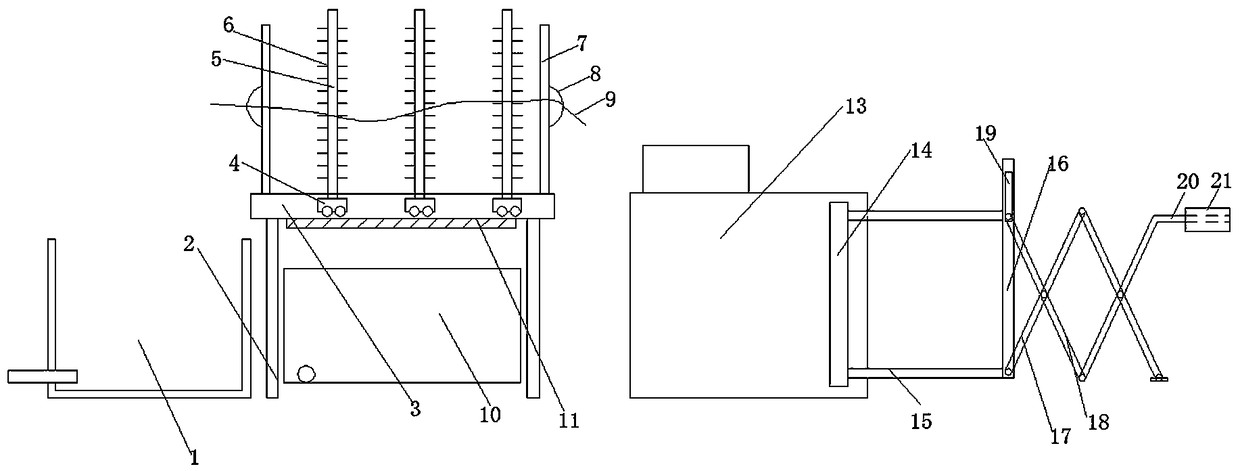

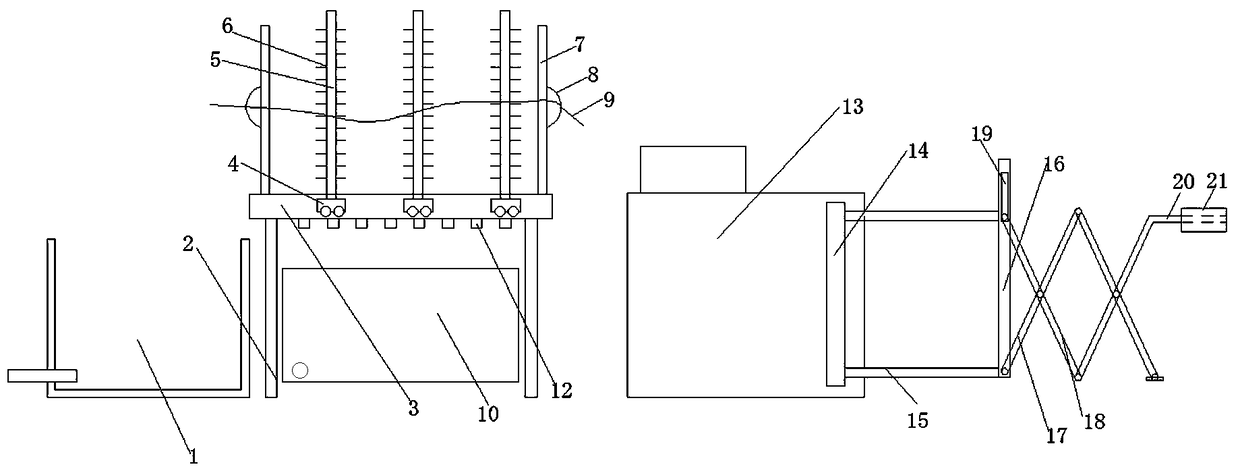

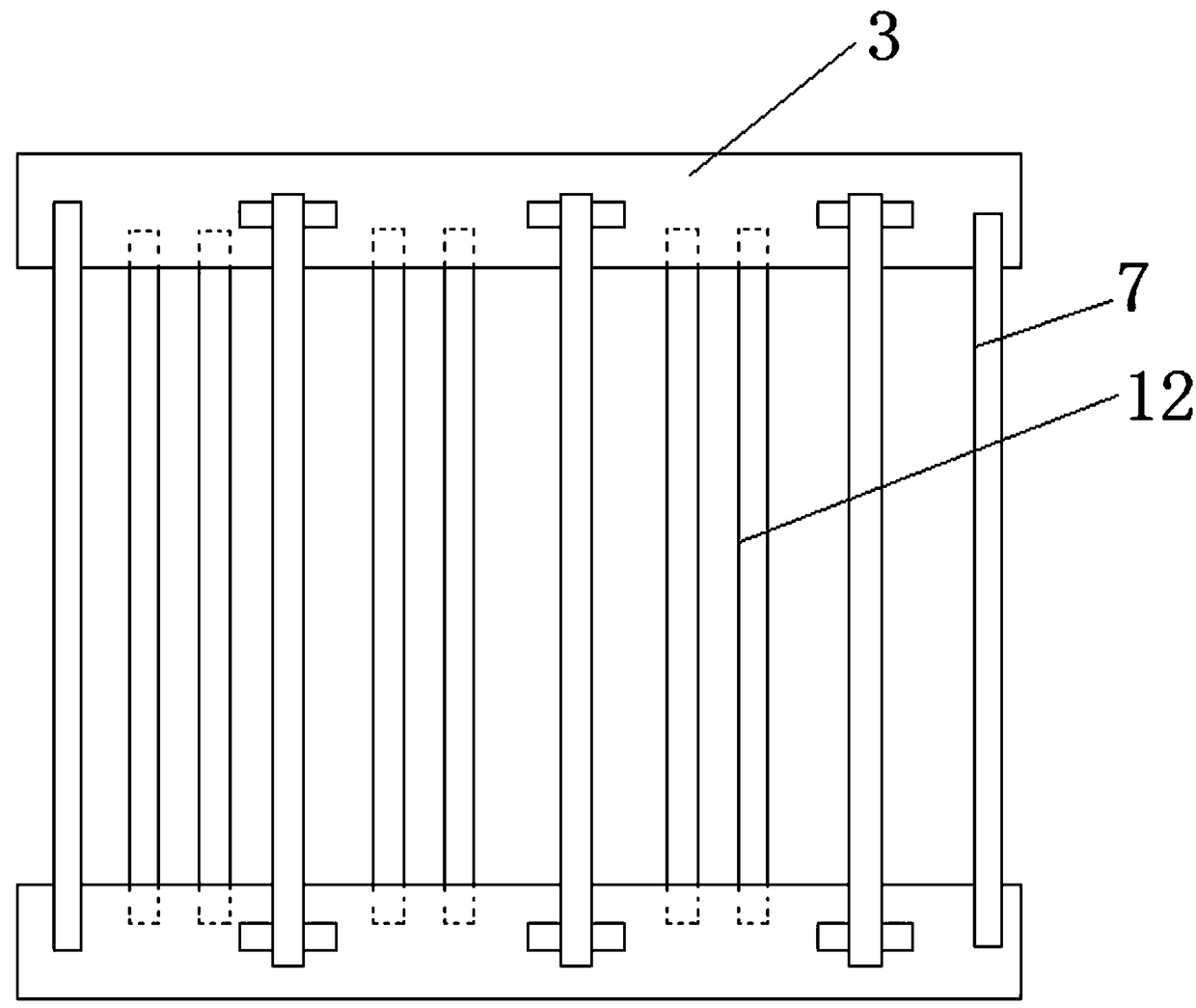

[0016] Such as figure 1 As shown, the present invention is a simple recovery device for plastic bottles, comprising a immersion pool 1 and a squeeze box 13, the lower end of the immersion pool has a water discharge hole, which is beneficial to the outflow of water, and a draining device is also arranged on one side of the immersion pool 1 , the draining device includes a bracket 2, two sliding grooves 3 are arranged in parallel on the bracket 2, and a partition plate 5 driven by a pulley 4 is set between the two sliding grooves 3. The pulley is Shenzhen Baoan The pulleys produced by Yanfeng Architectural Door and Window Fittings Firm in Xin'an District, there are two pulleys under each partition to facilitate the movement of the partition. Baffle plate 7 is also respectively set at the end, that is to say, there are respectively baffle plates on the left and right sides of the draining device, and hanging rings 8 are respectively arranged on the outside of said baffle plate 7,...

Embodiment 2

[0019] Such as Figure 2-3 As shown, the present invention is a simple recovery device for plastic bottles, comprising a immersion pool 1 and a squeeze box 13, the lower end of the immersion pool has a water discharge hole, which is beneficial to the outflow of water, and a draining device is also arranged on one side of the immersion pool 1 , the draining device includes a support 2, two sliding grooves 3 are arranged in parallel on the support 2, and a partition plate 5 driven by a pulley 4 is set between the two sliding grooves 3. The pulley is Shenzhen Baoan The pulleys produced by Yanfeng Architectural Door and Window Fittings Firm in Xin'an District, there are two pulleys under each partition to facilitate the movement of the partition. Baffle plate 7 is also respectively set at the end, that is to say, there are respectively baffle plates on the left and right sides of the draining device, and hanging rings 8 are respectively arranged on the outside of said baffle plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com