Filler strip for sectional material and production method thereof

A manufacturing method and a technology for a gasket, which are applied to the gasket for profiles and the production field thereof, can solve the problems of the felt gasket polluting the environment, increasing the production cost of the profile, and being easily worn by the felt gasket, achieving superior support and improving aesthetics. Good effect of sex and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention is capable of various changes in different embodiments without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

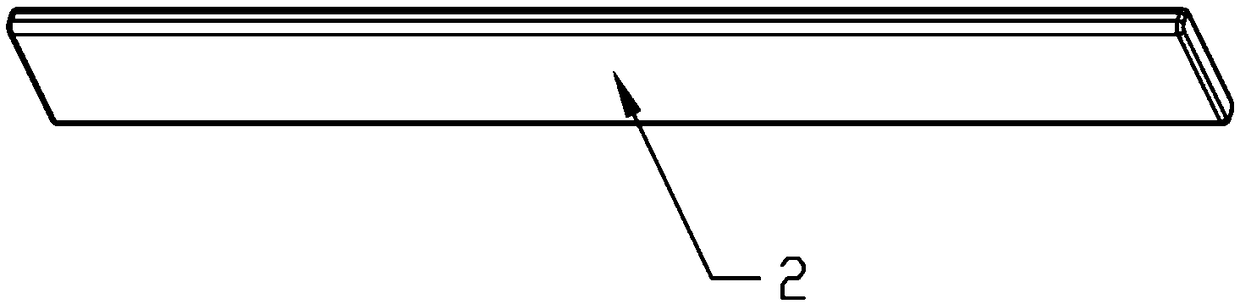

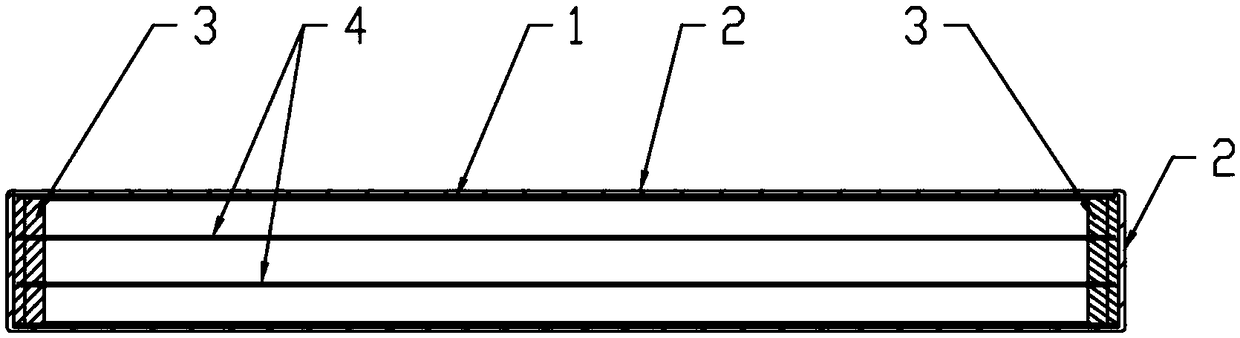

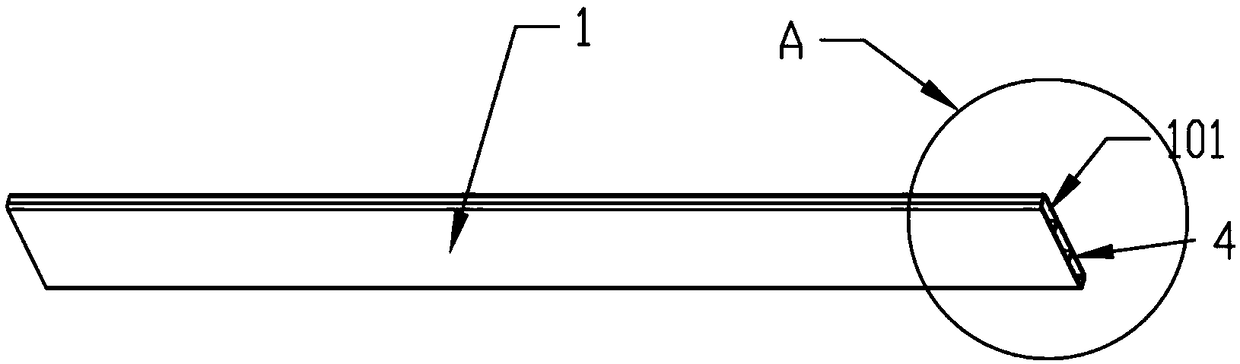

[0038] like figure 1 As shown, an embodiment of the present invention provides a pad for profile, including a skeleton 1 and a wrapping layer 2, the skeleton 1 is in the shape of a strip, and the skeleton 1 is provided with a vertically penetrating hollow structure inside, The hollow structure reduces the weight of the skeleton 1, ensuring that the overall weight of the pad is moderate; the wrapping layer 2 wraps the skeleton 1 as a whole, and the outer surface of the wrapping layer 2 is smooth, and the setting of the wrapping layer 2 ensures that the gap between the pad a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com