A multi-row chain chain hoist

A chain hoist and wall panel technology, which is applied in hoisting devices and clockwork mechanisms, etc., can solve the problems of large overall volume, increased material cost, and large hook spacing, and achieve the effect of saving space and reducing the hook spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

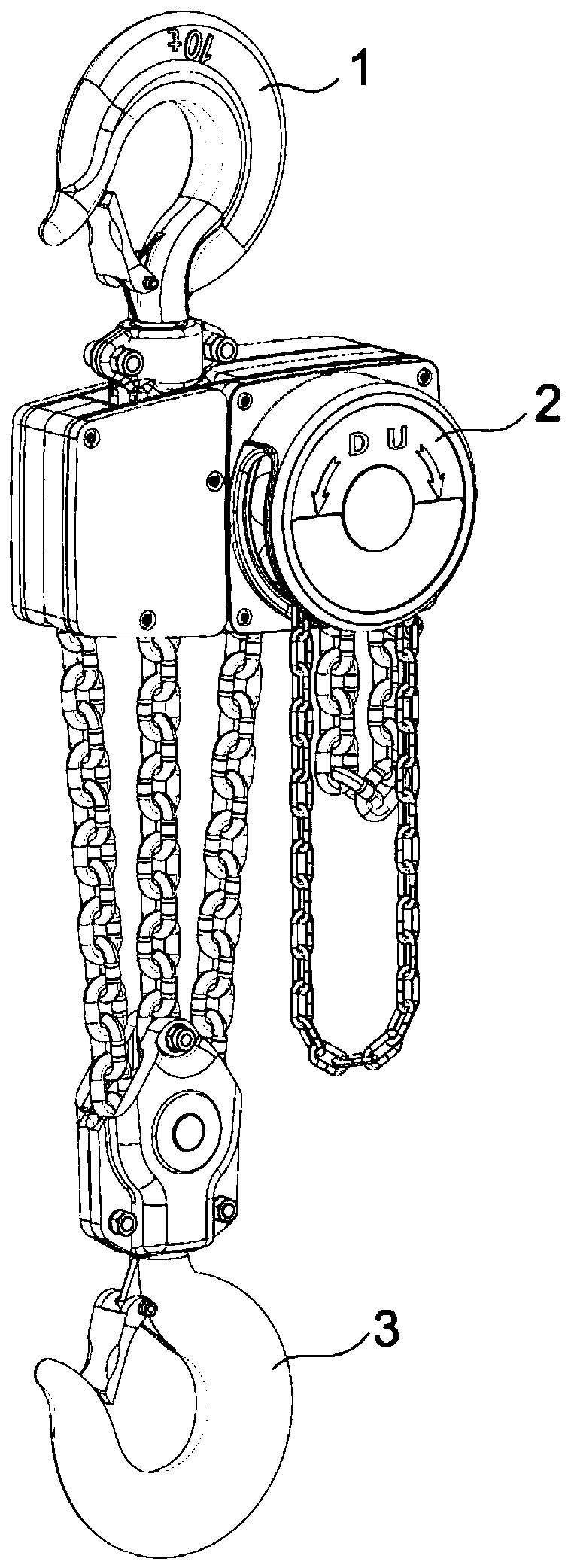

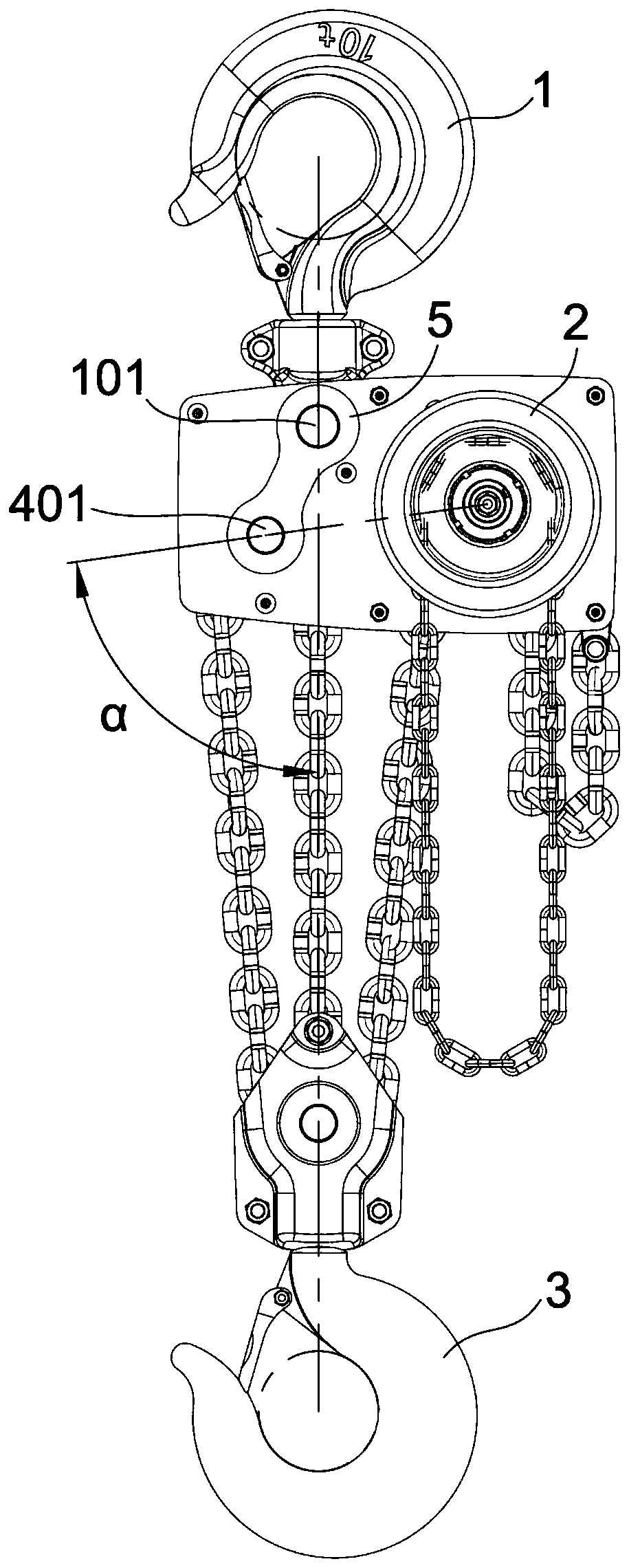

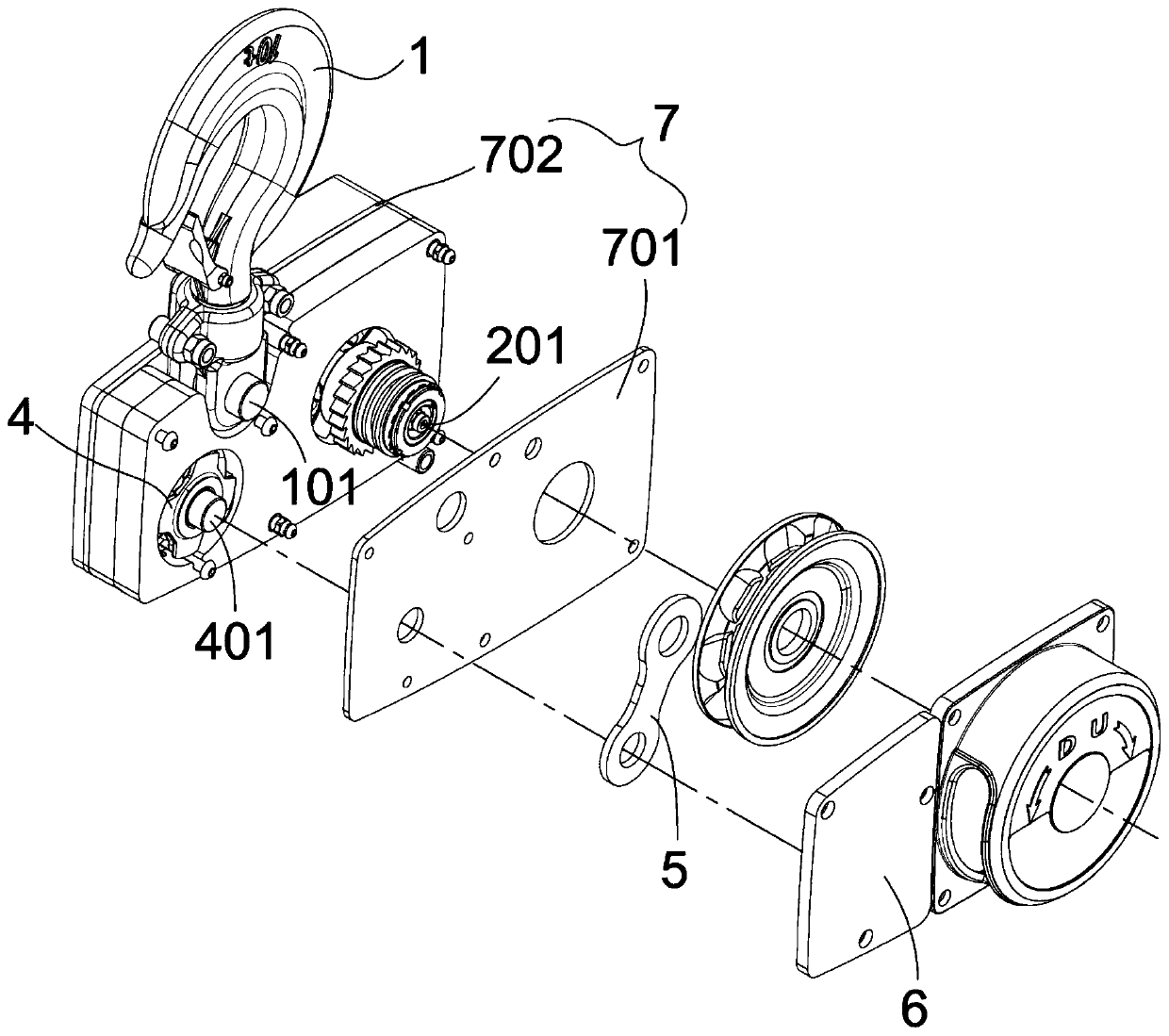

[0021] refer to Figure 1-3 , the three-chain chain hoist of the present invention includes an upper hook 1, a lower hook 3, a wall panel assembly 7, a main body mechanism 2 and a driven wheel mechanism 4, the upper hook 1 includes an upper hook shaft 101, and the main body mechanism 2 includes a hand chain wheel, Assemblies such as hand chain, ratchet, gear shaft 201, and driven wheel mechanism 4 then comprises driven wheel and driven shaft 401, and in the present embodiment, wallboard assembly 7 comprises first wallboard 701 and second wallboard 702, uses It is used to support the gear shaft 201 of the main body mechanism 2 , the upper hook shaft 101 of the upper hook 1 and the driven shaft 401 of the driven wheel mechanism 4 .

[0022] Both the main body mechanism 2 and the driven wheel mechanism 4 are arranged on the wall panel assembly 7, and there is a first axis connecting line between the axis center of the main body mechanism 2 and the axis center of the driven wheel ...

Embodiment 2

[0027] refer to Figure 4 , The difference between the four-chain chain block and the three-chain chain block in this embodiment is that the lifting chain is a four-row chain. The four-chain chain block also has an upper hook 1, a lower hook 3, a wall panel assembly 7, a main body mechanism 2 and a driven wheel mechanism 4. The main body mechanism 2 is arranged on the wall panel assembly 7, and the driven wheel mechanism 4 is arranged on the wall panel assembly 7. On the derivative structure of the wall panel assembly 7 where the main body mechanism 2 is located, so that the main body mechanism 2 and the driven wheel mechanism 4 are fixed on the wall panel assembly 7 in a horizontally side-by-side manner, which can reduce the width dimension and the vertical dimension, Therefore, the volume of the entire chain hoist is reduced, and the space layout is more compact.

[0028] Referring to the three-chain chain hoist and the four-chain chain hoist, other multi-row chain chain ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com