Self-sealing double-layer horizontal rotary disk cinder valve

A technology of horizontal rotation and rotating disc, applied in the direction of sliding valve, valve device, engine components, etc., can solve the problem of lack of self-sealing function, and achieve the effect of smooth and fast cutting, small space structure, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

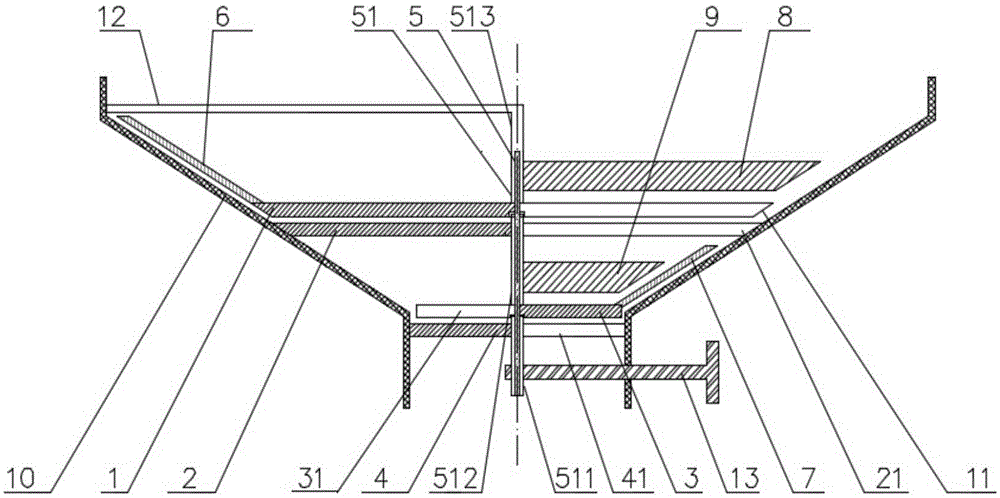

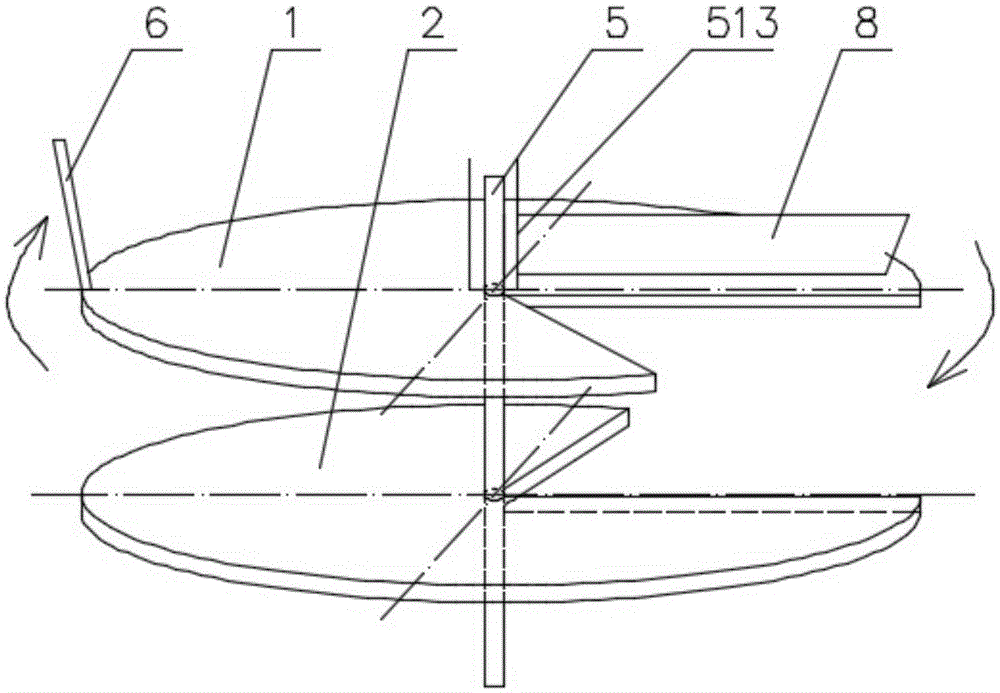

[0032] Such as figure 1 and figure 2 The shown self-sealing double-layer horizontal rotary disc dust discharge valve includes an inverted conical shell 10, the lower end of which is sealed and fixed to the lower sealing disc 4, and the lower sealing disc 4 has a lower sealing disc feeding port 41, a rotating shaft 5 penetrates into the casing 10 from the center of the lower sealing disc 4, and a transmission rod 13 cooperates with the rotating shaft 5, so that the rotating shaft 5 can rotate around its own center line. There is a shaft sleeve 51 on the outer ring of the rotating shaft 5, and the The centerline coincides with the centerline of the rotating shaft 5;

[0033] There is a lower rotary disk 3 on the upper side of the lower sealing disk 4, the center of the lower rotary disk 3 is sealed and fixedly connected with the rotating shaft 5, and the lower rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com