CMA biomass ash-doped phosphate cement for rescue and disaster relief

A technology of phosphate cement and biomass ash, applied in the direction of cement production, etc., can solve the problems such as cost reduction of modification of phosphate cement-based materials without CMA biomass ash, and achieve the effects of simple construction, cost reduction and obvious economic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

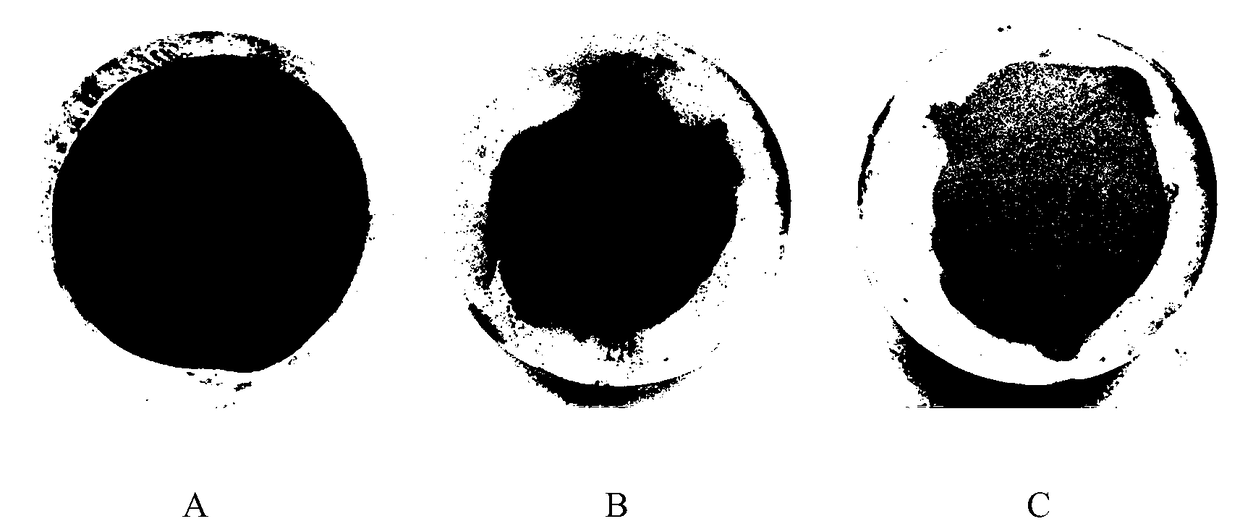

Image

Examples

Embodiment 1

[0022] Phosphate cement for rescue and disaster relief mixed with CMA biomass ash, dead-burned magnesia, borax, NH in a weight ratio of 1:0.05:0.2:0.15:0.01 4 h 2 PO 4 、KH 2 PO 4 and CMA500 composition.

[0023] The test results and benchmark cement results are shown in Table 1. The benchmark cement is phosphate cement without CMA.

[0024] Table 1 Performance comparison between phosphate cement mixed with CMA500 and phosphate cement without CMA (reference cement)

[0025]

Embodiment 2

[0027] Phosphate cement for rescue and disaster relief mixed with CMA biomass ash, dead-burned magnesia, borax, NH in a weight ratio of 1:0.04:0.2:0.15:0.05 4 h 2 PO 4 、KH 2 PO 4 And CMA650 composition. The test results and benchmark phosphate cement results are shown in Table 2.

[0028] Table 2 The performance comparison between the phosphate cement mixed with CMA650 and the phosphate cement without CMA (reference cement)

[0029]

Embodiment 3

[0031] Phosphate cement for rescue and disaster relief mixed with CMA biomass ash, dead-burned magnesia, borax, NH in a weight ratio of 1:0.02:0.2:0.15:0.05:0.1 4 h 2 PO 4 、KH 2 PO 4 and CMA800 composition. The test results and benchmark phosphate cement results are shown in Table 3.

[0032] Table 2 Performance comparison between phosphate cement mixed with CMA800 and phosphate cement without CMA (reference cement)

[0033]

[0034] (1) Compared with phosphate cement without CMA (base phosphate cement), the protected phosphate cement has fast setting and rapid hardening performance, and the setting time can be controlled within ten minutes, which can fully meet the requirements of rapid repair projects Need; the strength can reach more than 35.8MPa in 3 hours; it is used in cracks and holes in airport runways, concrete roads with heavy traffic, etc. It has simple construction, excellent performance, cheap price and obvious advantages.

[0035] (2) Studies have shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com