An all-organic engine coolant

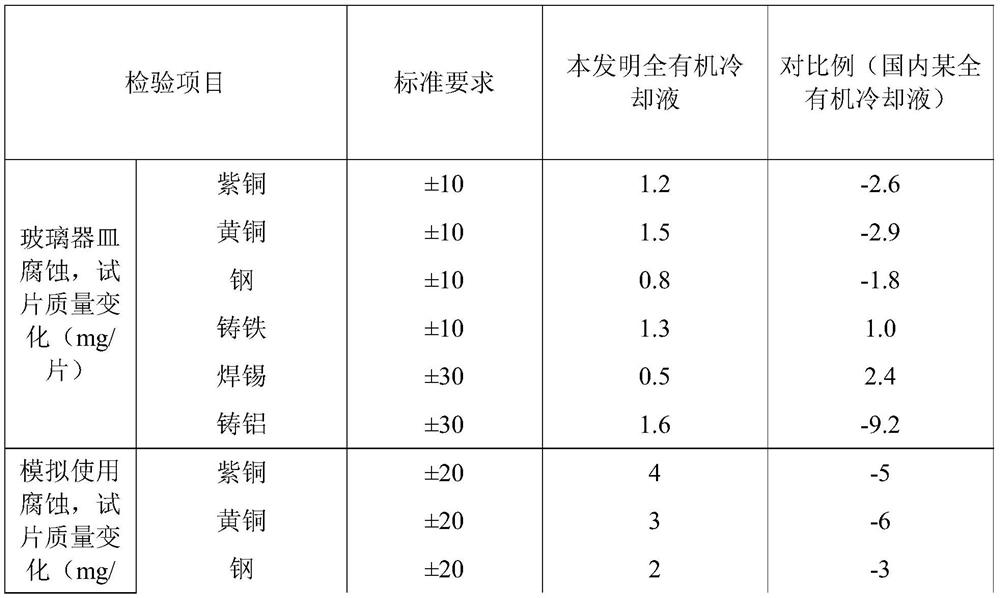

An engine coolant and organic technology, applied in the field of engine coolant, can solve the problems of cavitation corrosion, blackening of cast aluminum, etc., and achieve the effects of less environmental pollution, low foam and good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

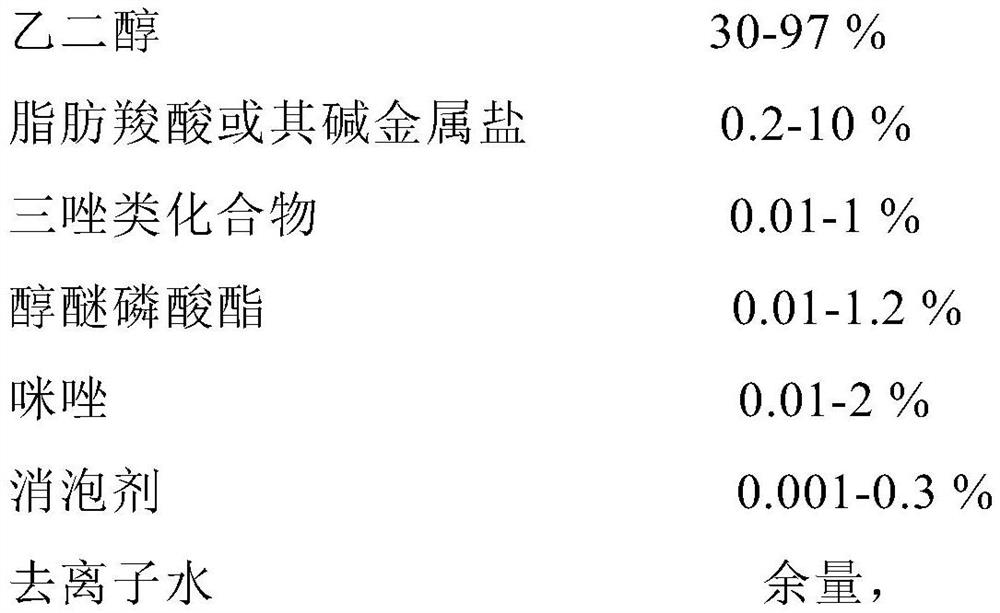

[0038]The raw material components and their mass fractions are: ethylene glycol 86%, neodecanoic acid 1.2%, sebacic acid 1.5%, tolyltriazole 0.5%, triethylene glycol monobutyl ether phosphate 0.6%, Triethylene glycol monomethyl ether phosphate 0.2%, imidazole 0.8%, polyether defoamer 0.05%, potassium hydroxide to adjust the pH value to 8, the balance is deionized water, heat and stir until uniform and transparent, and then filter to obtain Coolant of the present invention.

Embodiment 2

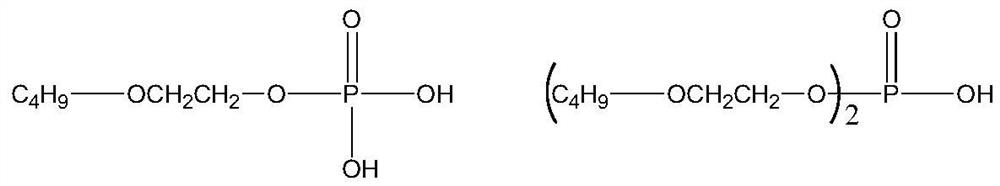

[0040] The raw material components and their mass fractions are: ethylene glycol 78%, octanoic acid 1.8%, isononanoic acid 0.5%, suberic acid 0.5%, dodecanedioic acid 1.5%, benzotriazole 0.8%, diethyl 0.9% glycol monobutyl ether phosphate, 1.4% imidazole, 0.1% polyether defoamer, potassium hydroxide to adjust the pH value to 8, and the balance is deionized water, heat and stir until uniform and transparent, and then filter to obtain the present invention of coolant.

Embodiment 3

[0042] The raw material components and their mass fractions are: ethylene glycol 93%, nonanoic acid 0.5%, capric acid 1.3%, suberic acid 0.4%, benzotriazole 0.1%, tolyltriazole 0.2%, Triethylene glycol monobutyl ether phosphate 0.05%, diethylene glycol monomethyl ether phosphate 0.02%, imidazole 0.3%, polyether defoamer 0.2%, potassium hydroxide to adjust the pH value to 8, and the balance is deionized water, heated and stirred until uniform and transparent, and then filtered to obtain the cooling liquid of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com