Stainless steel wine brewing device

A technology of stainless steel and equipment, applied in the field of brewing, can solve the problems of troublesome operation and easy sticking of waste materials on the inner wall of the steamer, and achieve the effect of avoiding trouble, improving efficiency, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

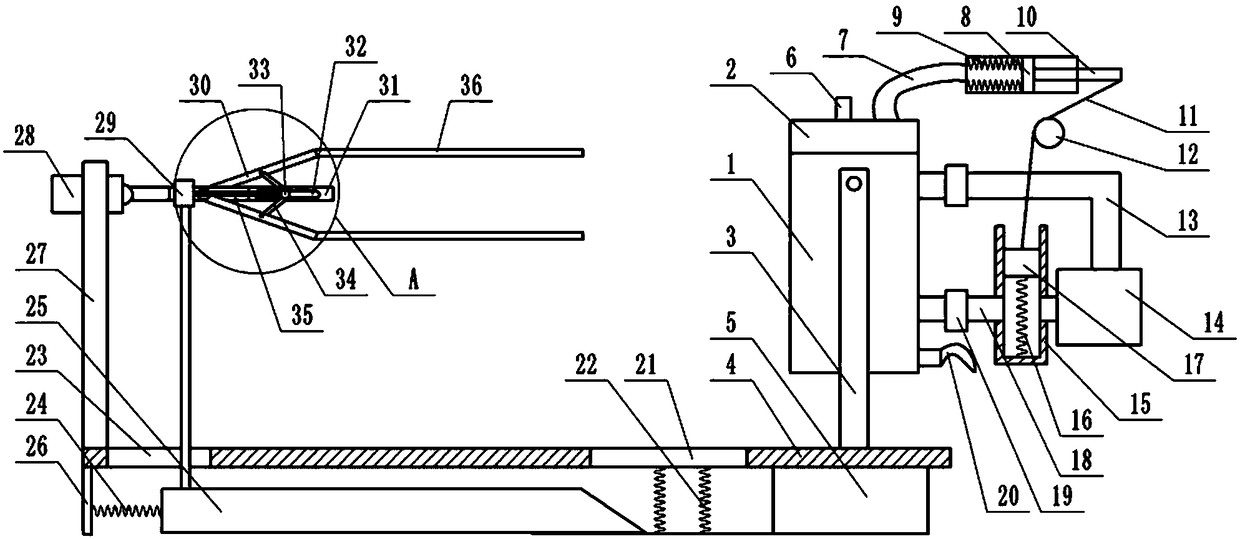

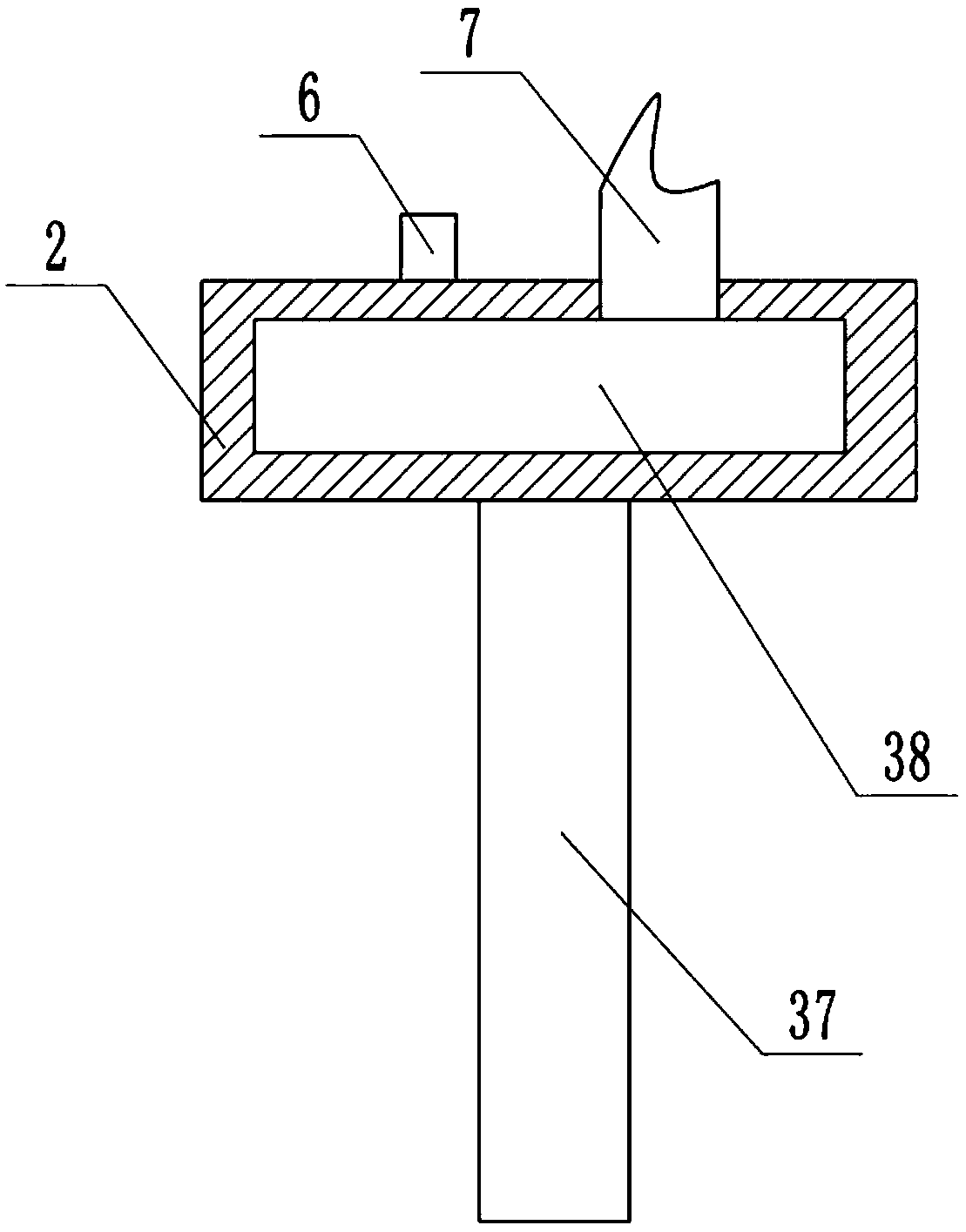

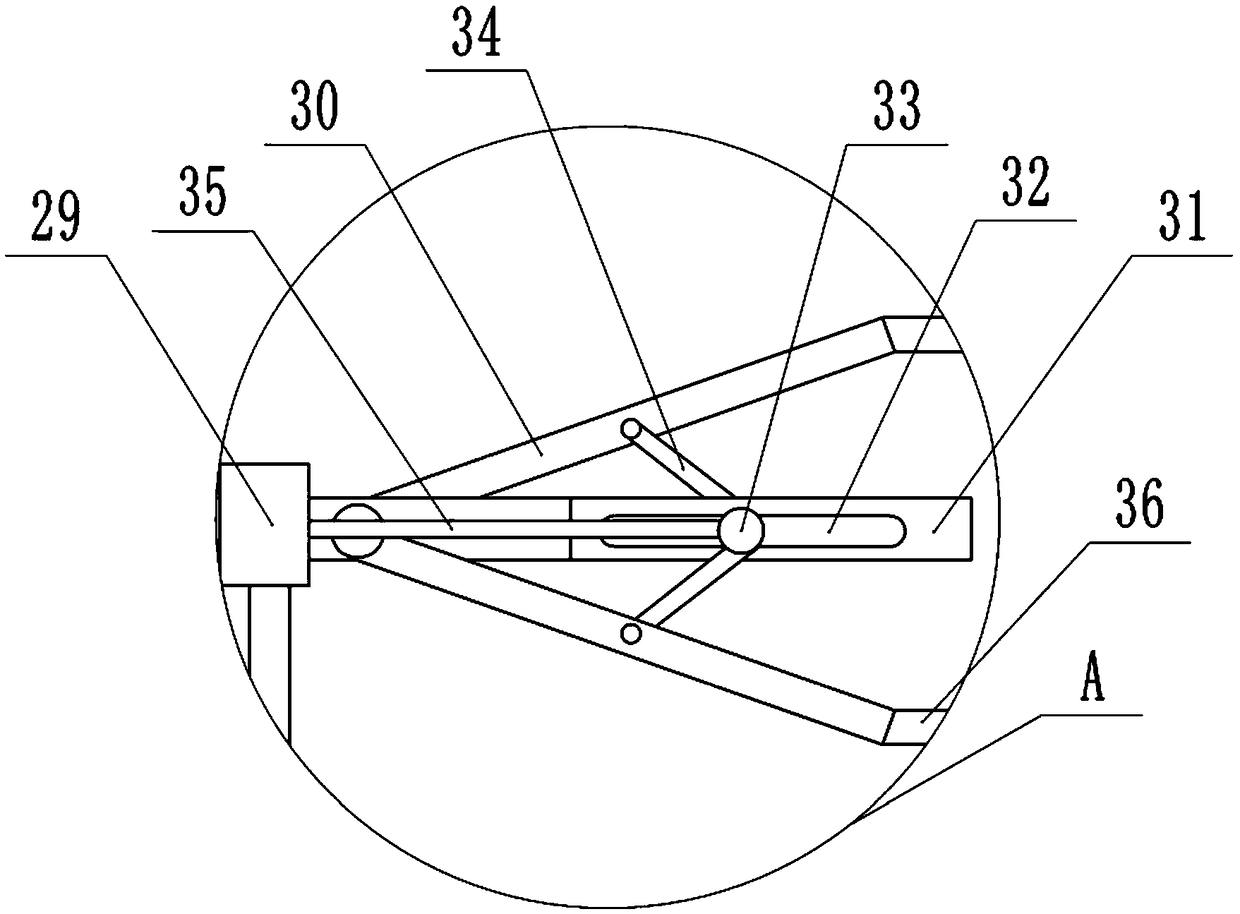

[0019] The reference signs in the accompanying drawings include: pot body 1, pot cover 2, column 3, base 4, heater 5, first hook 6, hose 7, piston 8, first extension spring 9, piston rod 10, Pull cord 11, rotating wheel 12, second through pipe 13, cold air generator 14, valve body 15, second tension spring 16, blocking block 17, first through pipe 18, connecting pipe 19, second hook 20, material plate 21. First compression spring 22, sliding hole 23, second compression spring 24, wedge 25, block 26, bracket 27, motor 28, bearing 29, adjustment rod 30, cross bar 31, bar hole 32, sliding post 33 , connecting rod 34, pull rod 35, scraper 36, heat conduction rod 37, air cavity 38.

[0020] The embodiment is basically as attached Figure 1-Figure 3 Shown: stainless steel brewing equipment, including a base 4, there is a certain gap between the base 4 and the ground. The base 4 is horiz...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap