Cross-linked film blow molding device

A technology of blow molding device and mounting frame, which is applied in the direction of transportation and packaging, other household utensils, winding strips, etc., which can solve the problems of inconvenient film inflation operation and inconvenient film automatic traction, so as to improve the uniformity of blowing degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

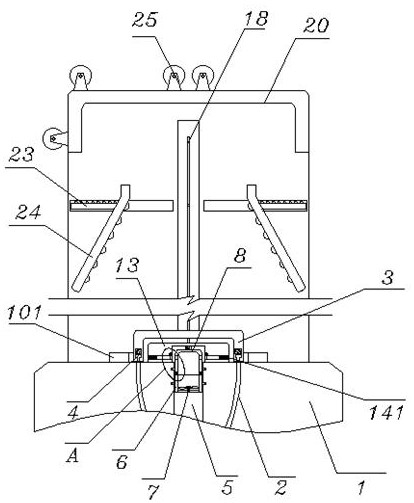

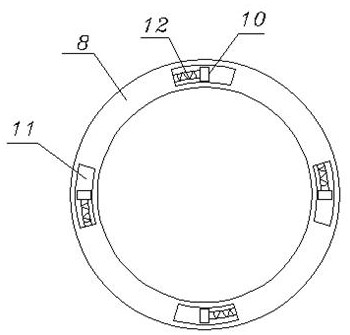

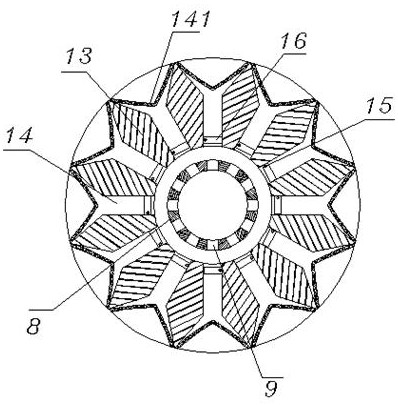

[0035] see Figure 1-5 , including the head 1, the head 1 is connected with the extruder at the bottom, and there is a blow molding channel 2 in the head 1, and a setting frame 3 is placed above the head 1, and a fan is installed on the head 1. Ring 101, the bottom of the shaping frame 3 is provided with a shaping channel 4, and the shaping channel 4 is located above the blowing channel 2, and the shaping frame 3 is filled with cooling water; The center position, and the bearing on the inner wall of the middle part of the gas transmission channel 5 is provided with a guide cylinder 6, and the bottom of the guide cylinder 6 is fixed with an impeller 7, a blowing cylinder 8 is installed above the guide cylinder 6, and the top edge of the blowing cylinder 8 is opened. There is a blowing hole 9, and the top of the blowing cylinder 8 is located above the handpiece 1, the top of the handpiece 1 is fixed with an air-guiding ring seat 13, and the air-guiding ring seat 13 is located be...

Embodiment 2

[0037] see figure 1 and Figure 6-8 , the screw 18, the screw 18 is installed on the top of the blowing cylinder 8, and the screw 18 is threadedly sleeved with a setting frame 3, the front and rear sides of the setting frame 3 are fixed with a limit rack 19, and one end of the limit rack 19 is The side wall of the mounting frame 20 is embedded and slidably installed, and the mounting frame 20 is fixed on the top of the machine head 1. The main gear 21 and the auxiliary gear 22 are mounted on the embedded bearing inside the mounting frame 20, and the main gear 21 and the auxiliary gear 22 are installed. They are connected by a synchronous belt, a movable rack 23 is meshed below the auxiliary gear 22, and the movable rack 23 is embedded in the mounting frame 20 and slides laterally, and one end of the movable rack 23 is fixed with a splint 24. The splint 24 is located at the inner position of the mounting frame 20, and the chevron splint 24 is located at the two sides of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com