Novel self-lubricating washing machine high-speed motor bearing

一种高速电机、自润滑的技术,应用在轴承元件、轴和轴承、机械设备等方向,能够解决不利于轴承长时间使用、增加轴承安全问题等问题,达到提高寿命、增加轴承载荷、提高最大转速的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

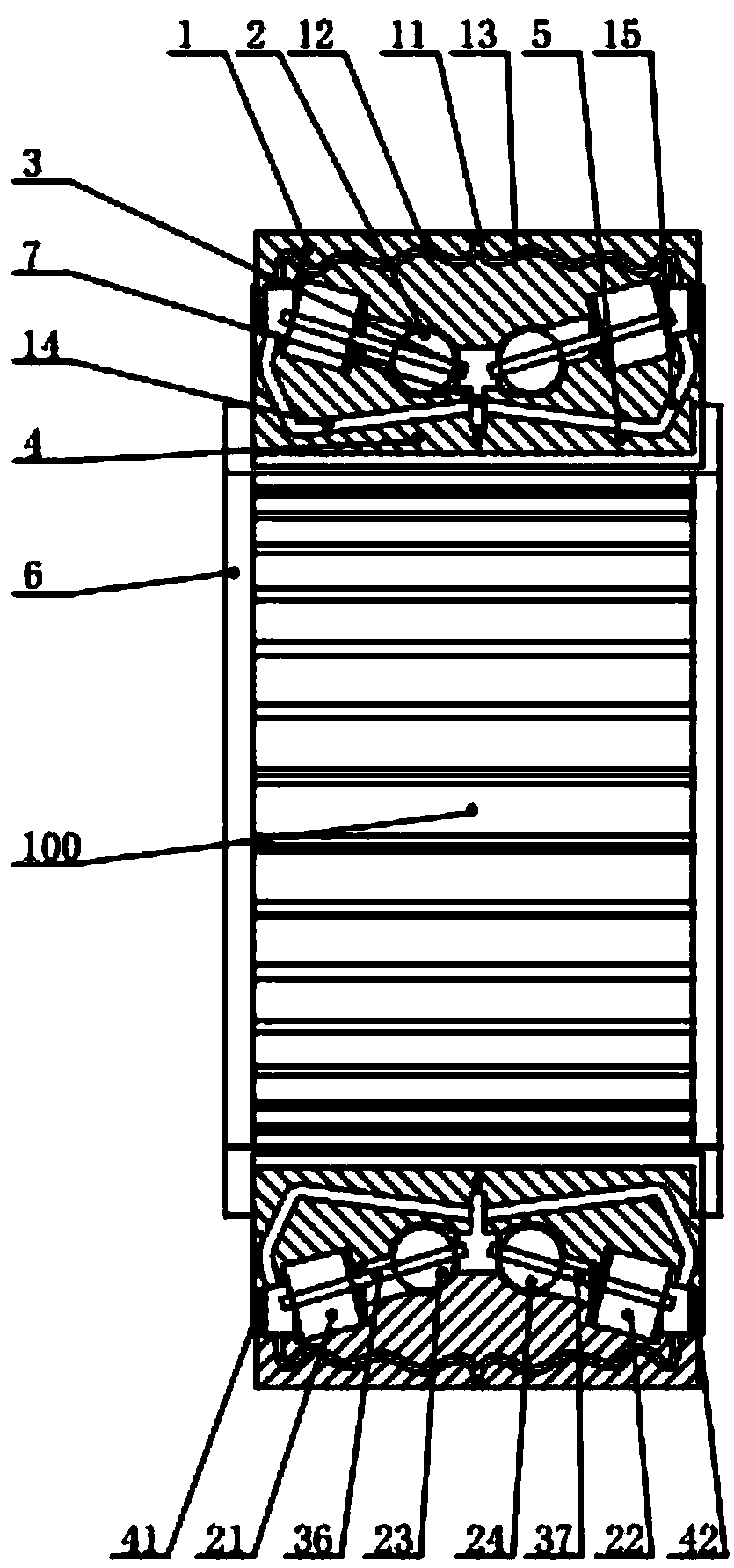

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

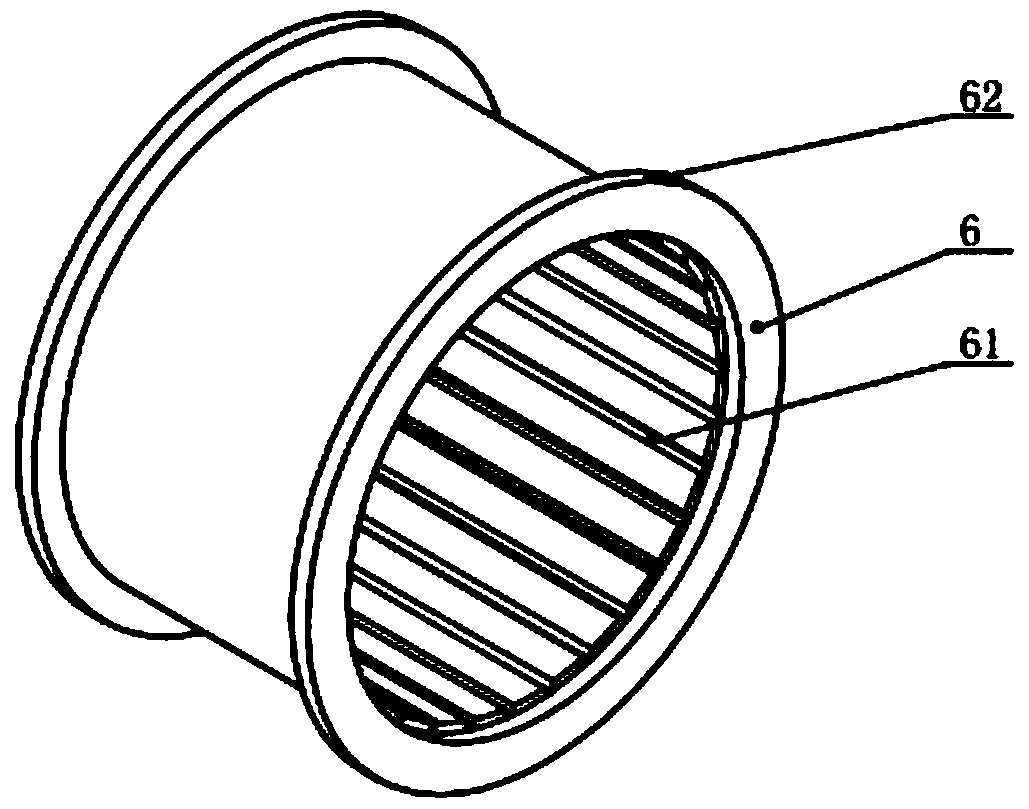

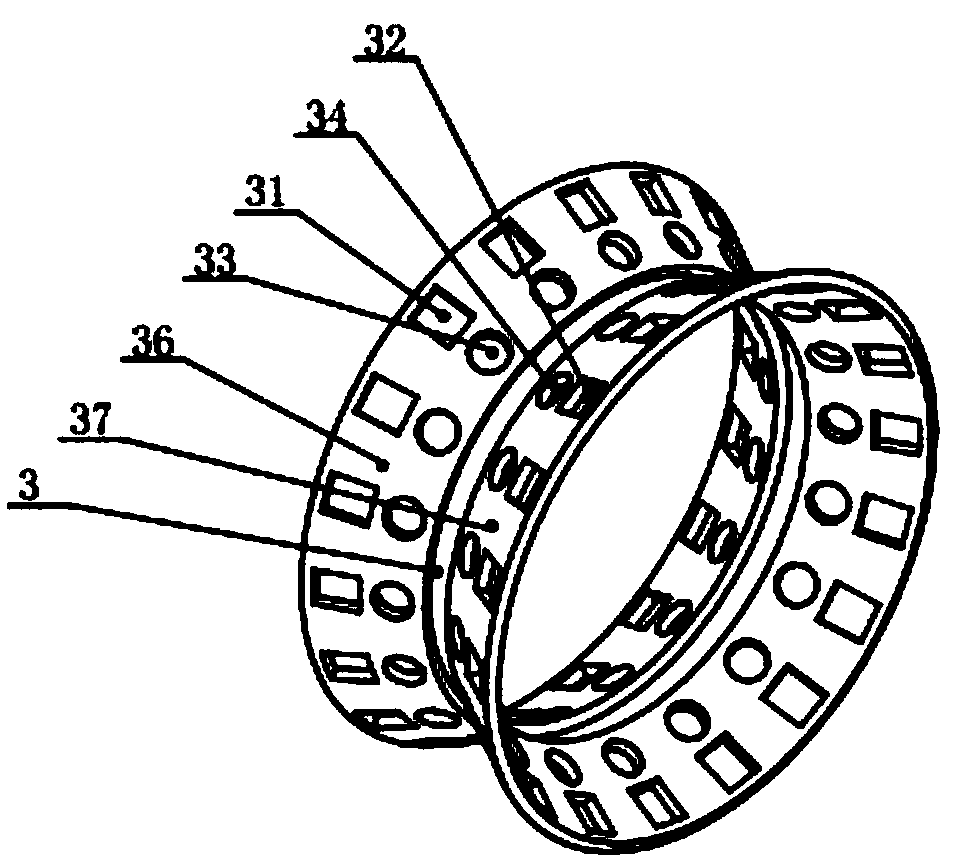

[0023] A kind of novel self-lubricating washing machine high-speed motor bearing of the embodiment of the present invention, as figure 1 As shown, including the bearing body 100, the bearing body 100 is provided with an outer ring 1, a rolling body 2, a cage 3, an inner ring 1, an inner ring 2 5 and an inner shaft sleeve 6 in sequence from outside to inside, and the inner ring 1 4 and the inner Ring two 5 are arranged side by side; rolling elements 2 include cylindrical roller one 21 and cylindrical roller two 22 arranged outside inner ring one 4 and inner ring two 5 respectively, and inner ring one 4 and inner ring two 5 respectively The first ball 23 and the second ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com