Multi-point wall temperature measuring device for rod bundle fuel assembly under motion condition

A fuel assembly and measuring device technology, which is applied to measuring devices, measuring heat, thermometers using electrical/magnetic elements directly sensitive to heat, etc., can solve the difficulty in obtaining thermal parameters of fuel assemblies and cannot ensure accurate thermocouple measurement. It can reduce the heat conduction path, realize disassembly and installation, and facilitate disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

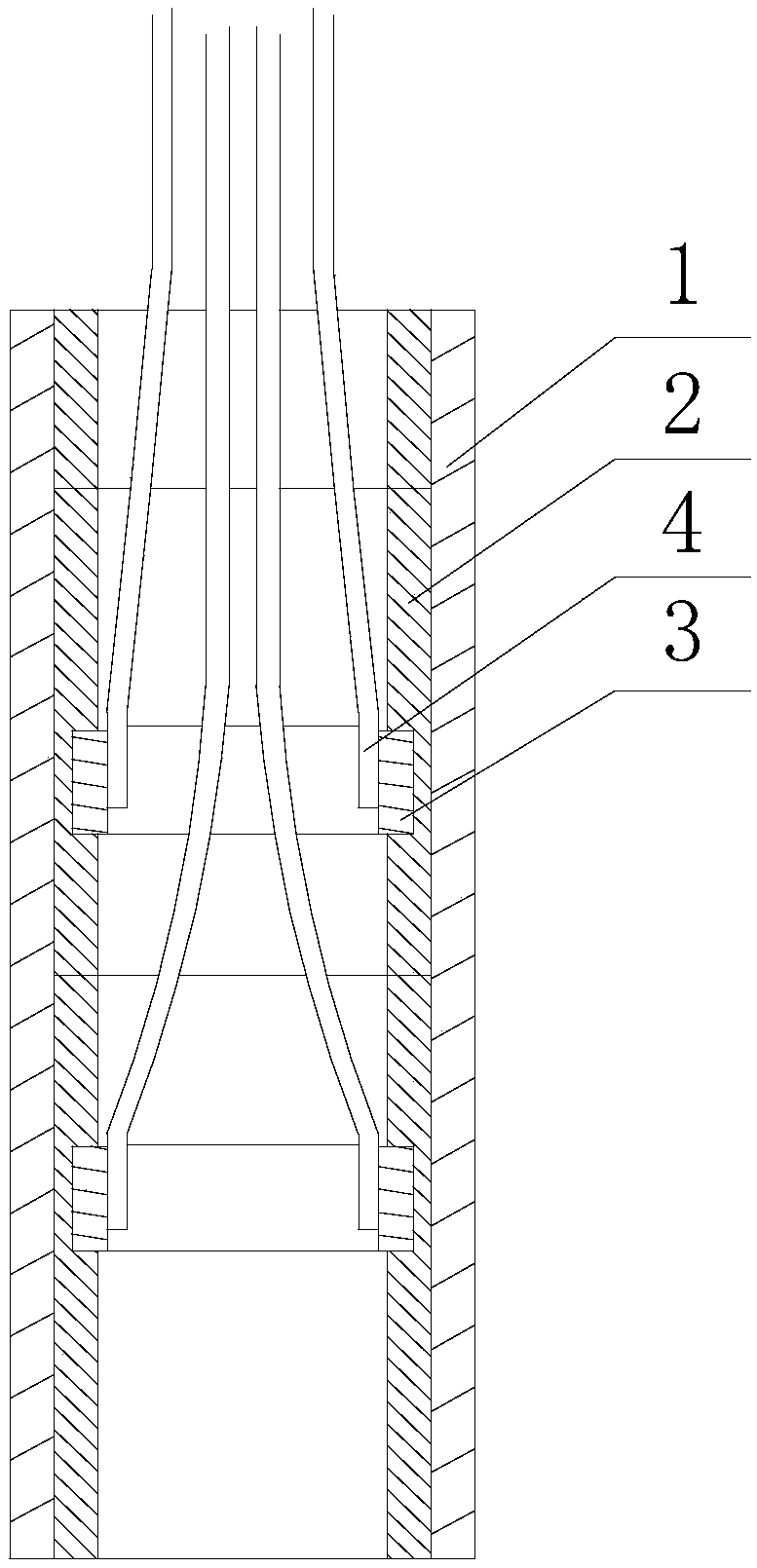

[0019] Such as figure 1 As shown in Fig. 2, the present embodiment includes at least one insulating ceramic tube 2, and an annular groove is formed on its inner peripheral wall along the circumferential direction of the insulating ceramic tube 2, and the temperature measuring ring 3 is arranged in the annular groove, and in the At least one armored thermocouple 4 is provided on the inner wall of the temperature measuring ring 3 . In view of the particularity of the structure of the existing rod bundle fuel assemblies and the complexity of the component flow field and temperature field under motion conditions, which leads to the difficulty in obtaining thermal parameters such as the wall temperature of the fuel assembly, the applicant simulated the rod bundle fuel assembly When carrying out the experimental research on heat transfer characteristics, the metal round tube is used for heating with electricity as the heating element tube 1, and at least one insulating ceramic tube ...

Embodiment 2

[0022] Such as figure 1As shown in FIG. 2 , in this embodiment, the armored thermocouple 4 is welded in the annular groove by silver-based solder. The annular groove is used as the installation carrier of the armored thermocouple, and the armored thermocouple 4 is welded in the annular groove. The welding method is silver brazing. After being solidified and connected, the brazing filler metal can flow evenly to fill the gap between the annular groove and the armored thermocouple 4. On the other hand, the filling material used for silver brazing is silver-based brazing filler metal, and its main components are silver-copper and silver-copper The zinc alloy maintains good thermal conductivity between the armored thermocouple 4 and the temperature measuring ring 3 to improve the accuracy of the final temperature value measured by the armored thermocouple 4 .

[0023] Preferably, the number of armored thermocouples 4 is 1 to 4, so that after the temperature measurement points on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com