Non-intrusive winding temperature measurement method for forced oil circulation air-cooling cake type winding transformer

A technology of forced oil circulation and pie-type winding, which is applied in the field of transformers, can solve problems such as complex structures, affecting transformer insulation, sealing performance, and large measurement errors, and achieve accurate measurement and timely and reliable trip signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

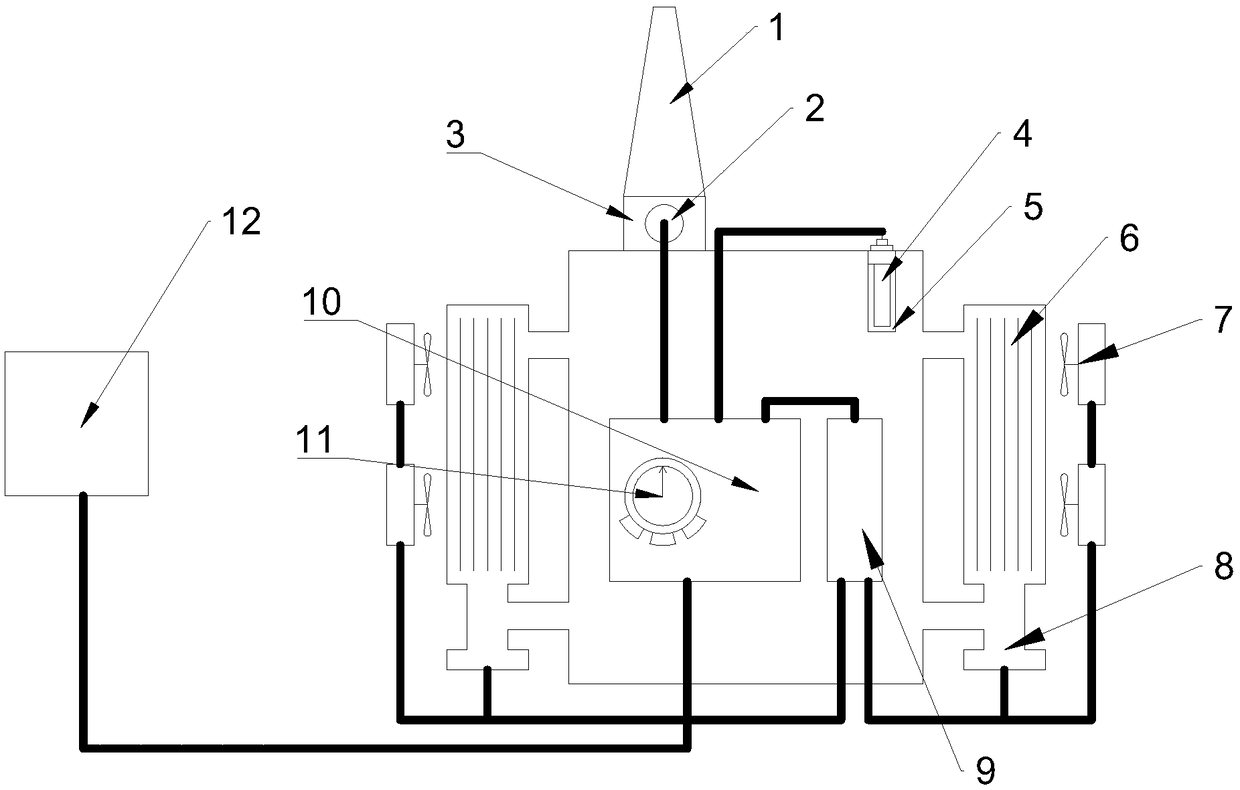

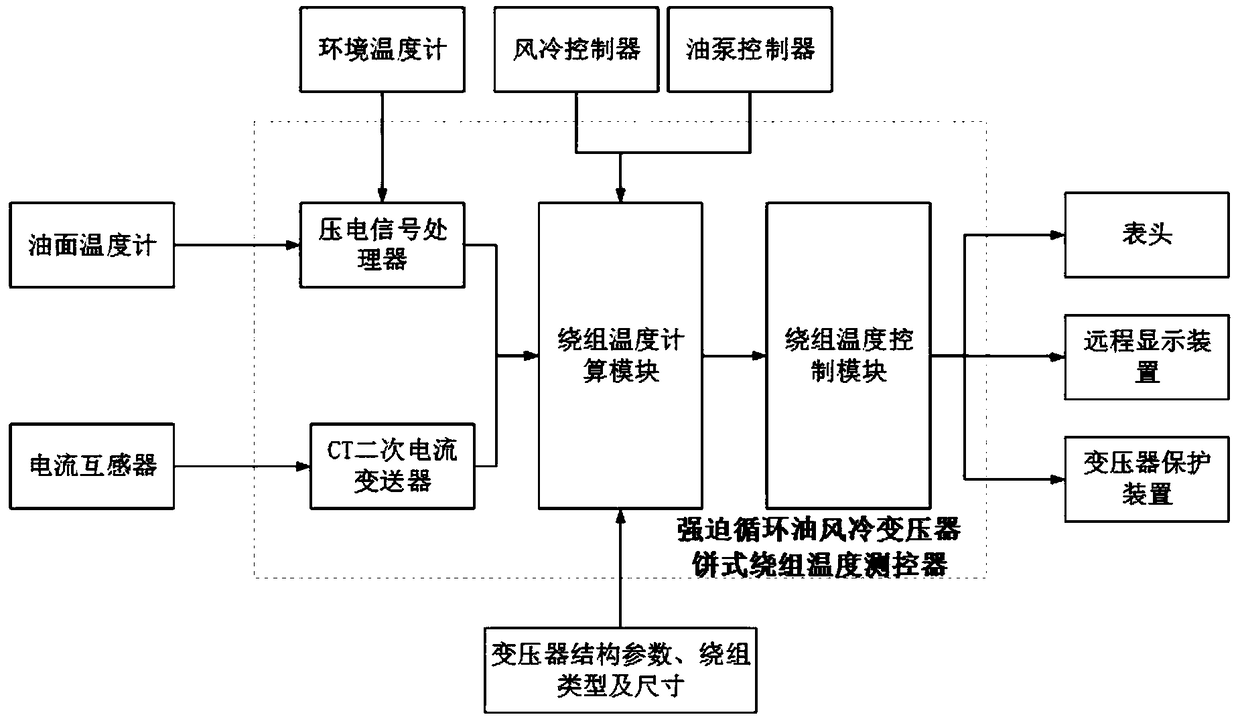

[0050] A non-intrusive winding temperature measurement method for forced oil circulation air-cooled cake winding transformers, which is figure 1Realized on the winding temperature measurement system shown, the transformer riser 3, transformer bushing 1, terminal box 10, cooler control box 9, cooler 6, and fan 7 are installed on the forced oil circulation air-cooled cake winding transformer , Submersible oil pump 8, thermometer oil cup 5. The terminal box and the cooler control box are installed on the side wall of the transformer, and a forced oil circulation air-cooled transformer cake winding temperature controller and an ambient thermometer are installed in the terminal box, and a meter 11 is installed on the surface of the terminal box. An air-cooling controller and an oil pump controller are installed in the cooler control box, and the air-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com