Method for non-destructively detecting segmented suction resistance of cigarettes

A non-destructive testing, cigarette technology, applied in measurement devices, analytical materials, permeability/surface area analysis, etc., can solve problems such as negative resistance of suction, and achieve the effect of detection methods and measurement data science

Active Publication Date: 2018-11-30

ZHENGZHOU TOBACCO RES INST OF CNTC

View PDF6 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the implementation, since it is assumed that the cigarette paper and the shredded tobacco section are connected in parallel (this relationship is only applicable to a certain range of use), it is easy to appear that a section of draw resistance shows a negative value during detection.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment example

[0029] The present invention is further described in conjunction with the following examples:

[0030] Implementation case

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

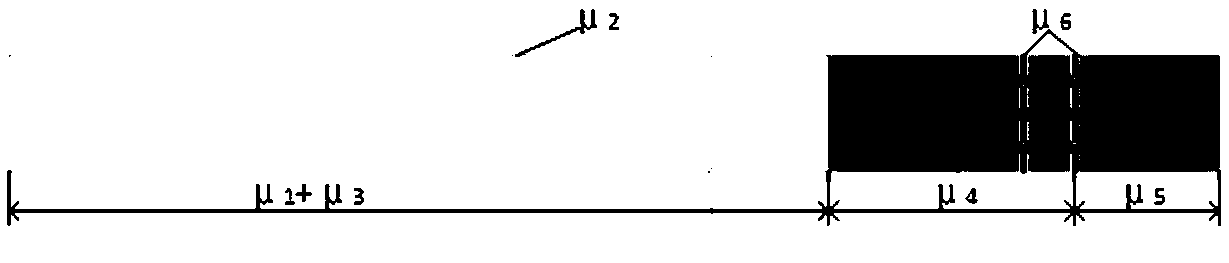

The invention relates to a method for non-destructively detecting segmented suction resistance of cigarettes and belongs to the technical field of cigarette quality detection. The method utilizes thebasic feature of flow conservation and quasi-series of air flows passing through a cigarette, realizes measurement of the suction resistance of each part of the cigarette based on a cigarette suctionresistance measurement method, independently acquires closed suction resistance data of a filter tip section and a cigarette section without mechanically separating the filter tip section and the cigarette section, determines that the permeation resistance of the whole filter tip laser-punched cigarette is composed of five permeation resistance values according to the cigarette suction resistanceformation theoretical basis that the pressure of flows passing through the cigarette is in direct proportion to the amount of flows passing through the cigarette and the ratio is cigarette permeationresistance (unit: Pa. s / ml) which is a physical property parameter, and calculates segmented suction resistance values of all parts of the cigarette. The method can satisfy the actual engineering demands of providing the basic support for cigarette product quality traceability, product design and process optimization.

Description

Technical field: [0001] The invention relates to the technical field of cigarette quality detection, in particular to a method for non-destructive detection of segmental draw resistance of cigarettes. Background technique: [0002] Cigarette draw resistance is one of the important indicators of the physical quality of cigarette products, and its size has an important impact on the sensory quality and smoking difficulty of cigarette products. The measurement of the draw resistance of cigarettes usually adopts GB / T 22838.5-2009 "Determination of Physical Properties of Cigarettes and Filter Rods_Part 5: Cigarette Draw Resistance and Pressure Drop of Filter Rods", which can realize the fully automatic operation of cigarette draw resistance measurement With control, the above method realizes the measurement of cigarette open draw resistance and closed draw resistance. Through the measurement of cigarette draw resistance, we can know the quality of cigarettes and the level of cig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N15/08

CPCG01N15/0826

Inventor 李斌游敏张明建王乐邓楠张柯鲁端峰朱文魁堵劲松王兵

Owner ZHENGZHOU TOBACCO RES INST OF CNTC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com