Steel pipeline online ultrasonic detection device and method

A detection device, ultrasonic technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems of unguaranteed measurement accuracy, waste of materials, heavy workload, etc., to save labor, improve evaluation ability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

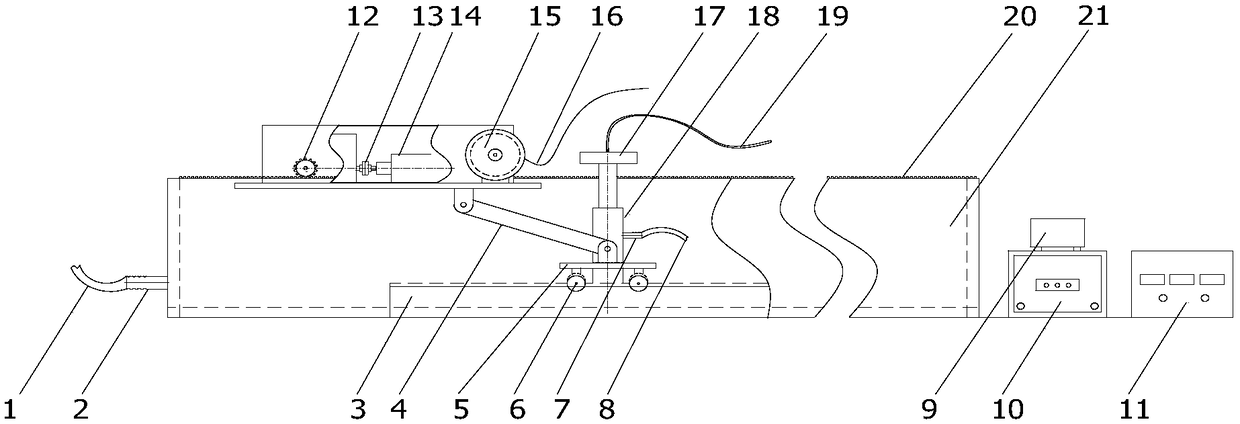

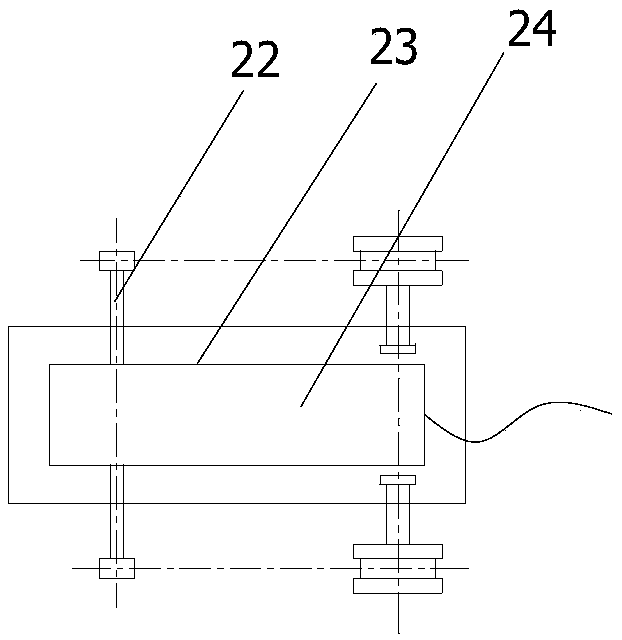

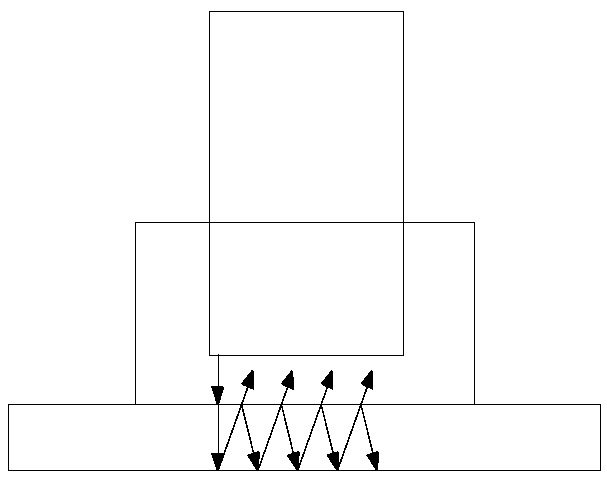

[0020] Such as figure 1 As shown, an online ultrasonic detection device and method for steel pipelines mainly includes a water collection tank 21, a driving device 24, a supporting rolling platform 5, a coupling device 18, an ultrasonic probe 17, a control system 10, an ultrasonic detector and a data acquisition system 11 , the measured steel pipeline 3 is placed in the middle of the water collection tank 21, the supporting rolling platform 5 is placed on the surface of the tested steel pipeline 3, and the rolling wheel 6 under the supporting rolling platform 5 can move axially along the measured steel pipeline 3; The top of the supporting rolling platform 5 is connected with the coupling device 18 and the ultrasonic probe 17 in turn; the driving device 24 is located above the sump 21 and can move along the track through the rack rail frame 20 installed above the sump 21; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com