part drilling machine

A technology for drilling machines and parts, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., which can solve the problems of excessive debris and labor, and achieve enlarged flushing area and good flushing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

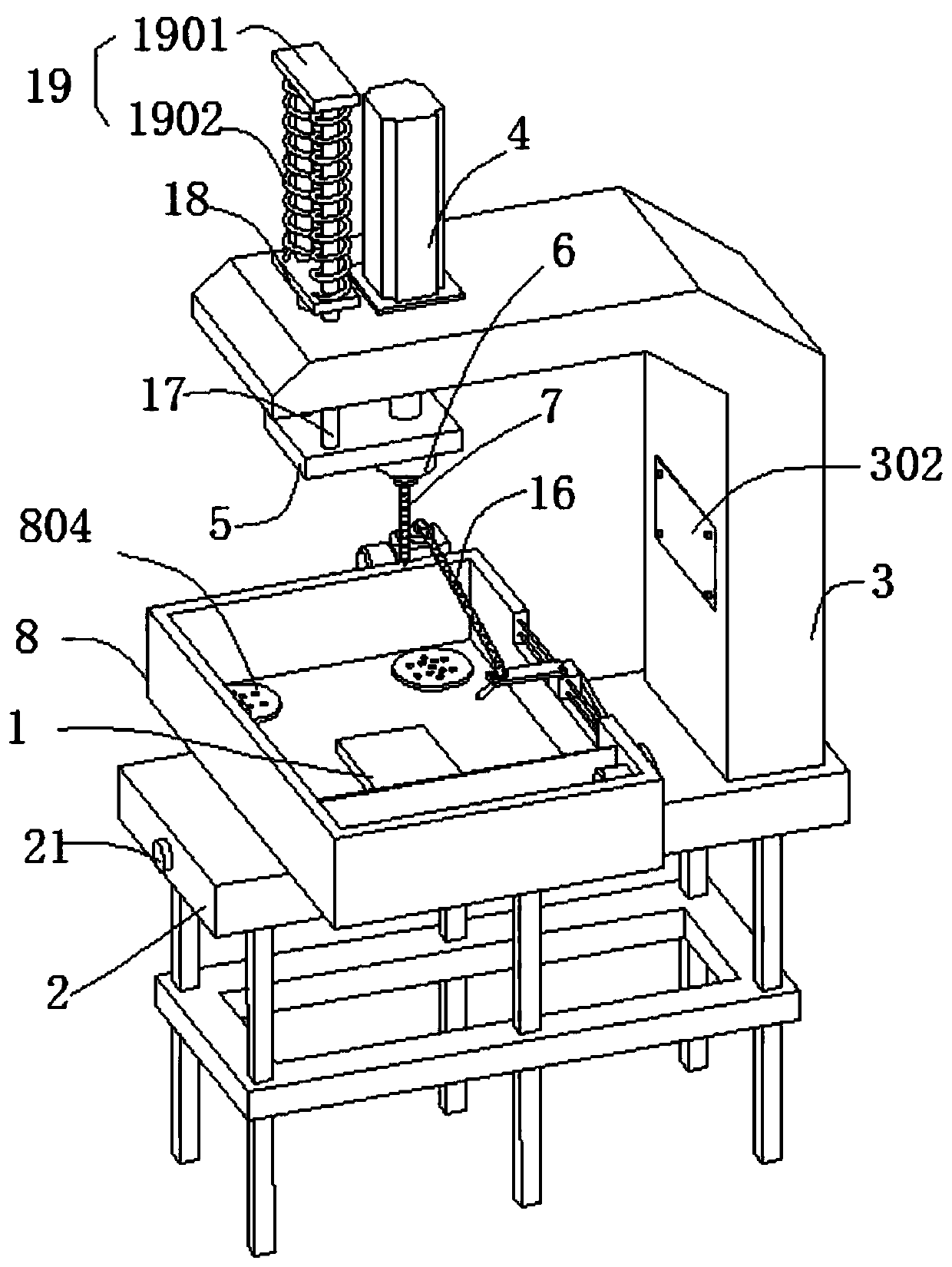

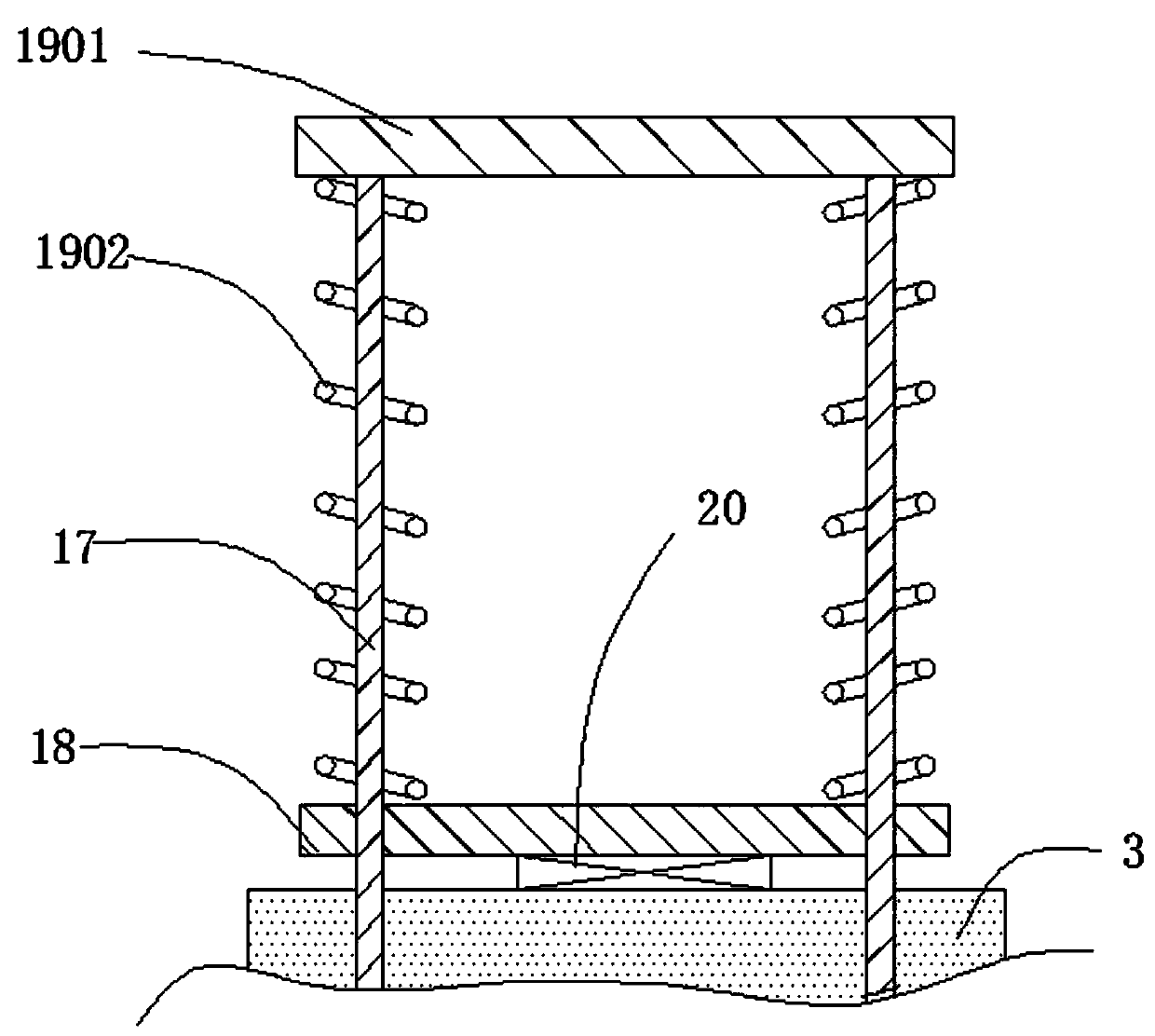

[0030] refer to figure 1 As shown, the present embodiment provides a part drilling machine, including a workpiece table 1, an underframe 2, a support arm 3 arranged on the underframe 2, a hydraulic cylinder 4 vertically arranged on the upper part of the support arm 3, and a mounting plate 5 vertically fixedly install the power head 6 on the output shaft of the hydraulic cylinder 4, and the drill bit 7 installed on the power head 6. Among them, the rotary head is mainly driven by the power head 6 to rotate, and the hydraulic cylinder 4 drives the power head 6 to move up and down to complete the drilling work.

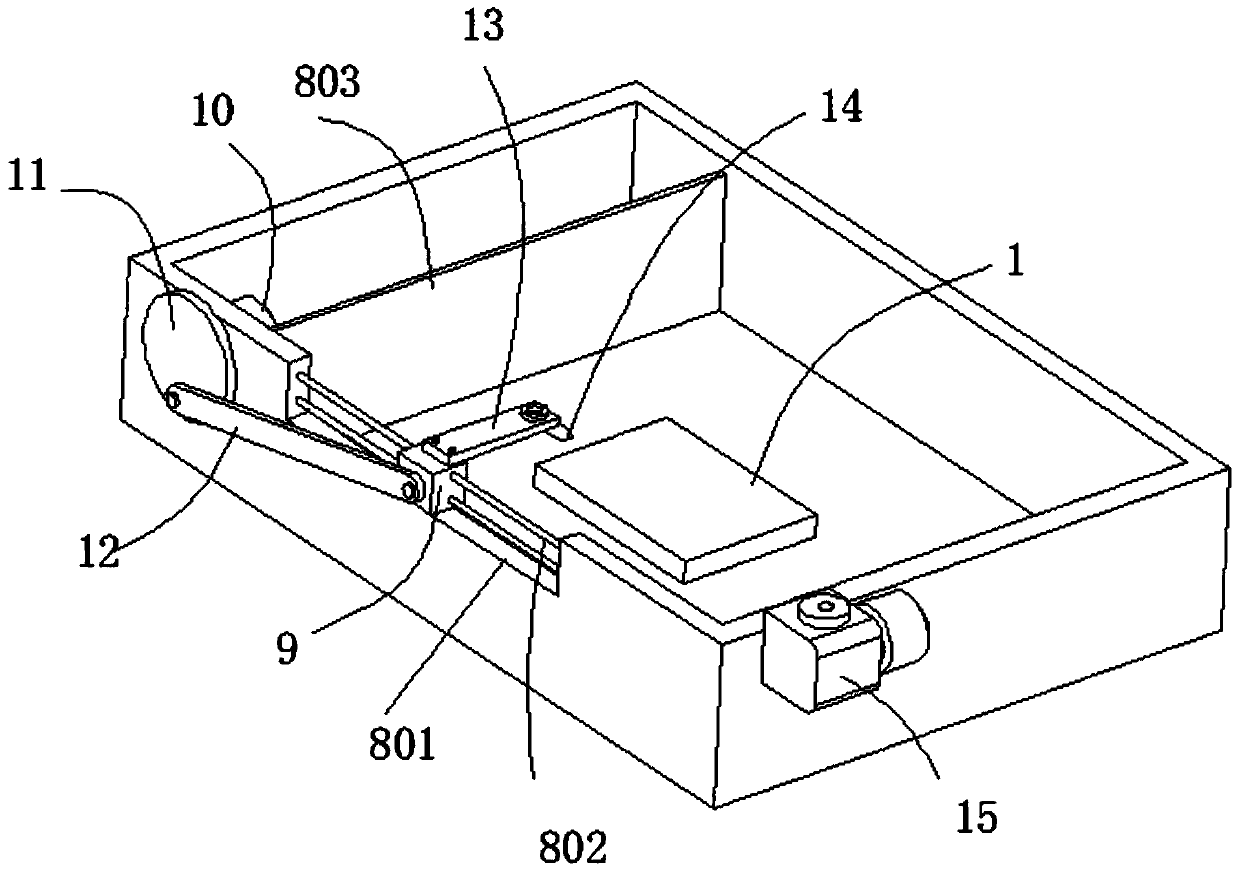

[0031] combine figure 2 As shown, it also includes a water tank 8 horizontally arranged on the chassis 2; the workpiece table 1 is arranged in the water tank 8; the side wall of the water tank 8 close to the support arm 3 is slidably connected with a slider 9; the water tank 8 passes through the partition 803 is divided into a working area and a water barrier area, wh...

Embodiment 2

[0046] On the basis of embodiment 1, in order to carry out drilling work more conveniently, embodiment 2 is provided here:

[0047] combine Figure 5 As shown, the side wall of the support arm 3 close to the side of the water tank 8 is provided with a light groove 301 with an LED lamp board 22 inside; wherein the notch of the light groove 301 is installed with a screw covering the notch of the light groove 301. A transparent cover plate 302 . The purpose of setting the LED lamp board 22 is to illuminate when drilling.

[0048] combine Figure 6 As shown, the LED light board 22 is electrically connected with an automatic control circuit; the automatic control circuit includes:

[0049] The light detection circuit 400 is used to detect the light intensity of the external environment, and output a corresponding light detection signal accordingly.

[0050] Specifically, the light detection circuit 400 includes a fifth resistor R5, a sixth resistor R6, a photosensitive resistor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com