Cell production and staining machine

A technology of cell production and all-in-one machine, which is applied in the preparation, sampling, and instrumentation of test samples, and can solve the problems of residual waste liquid and affecting the observation and use of slide 542.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

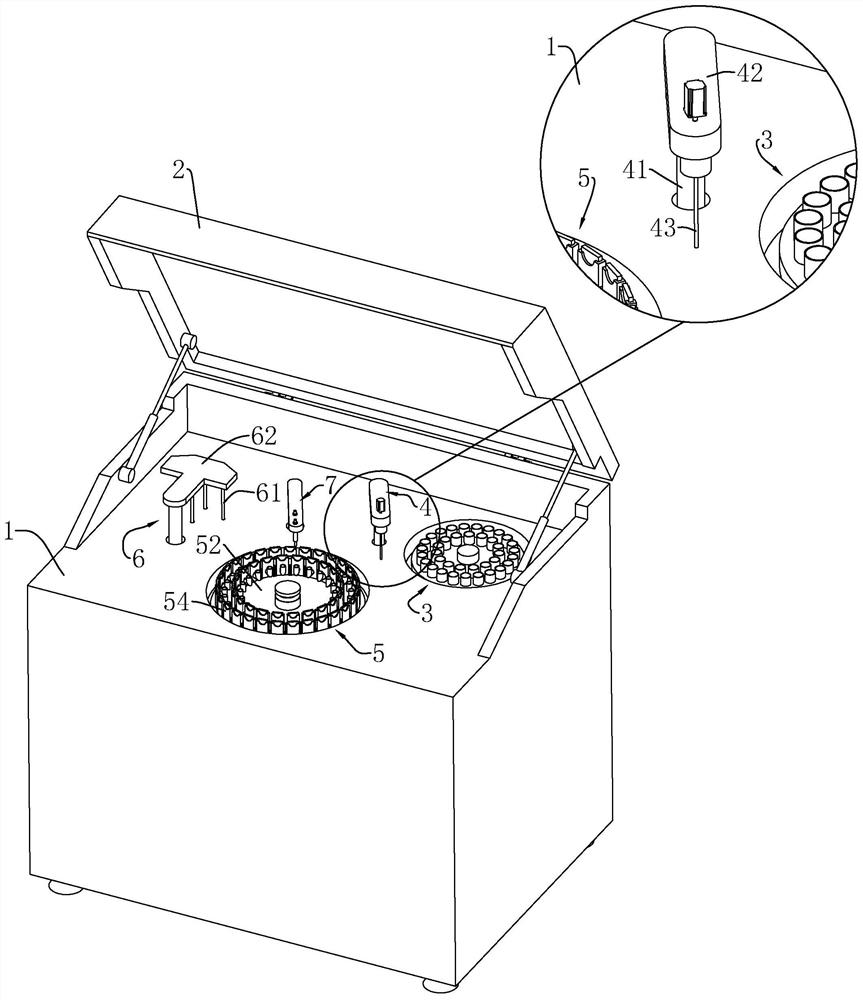

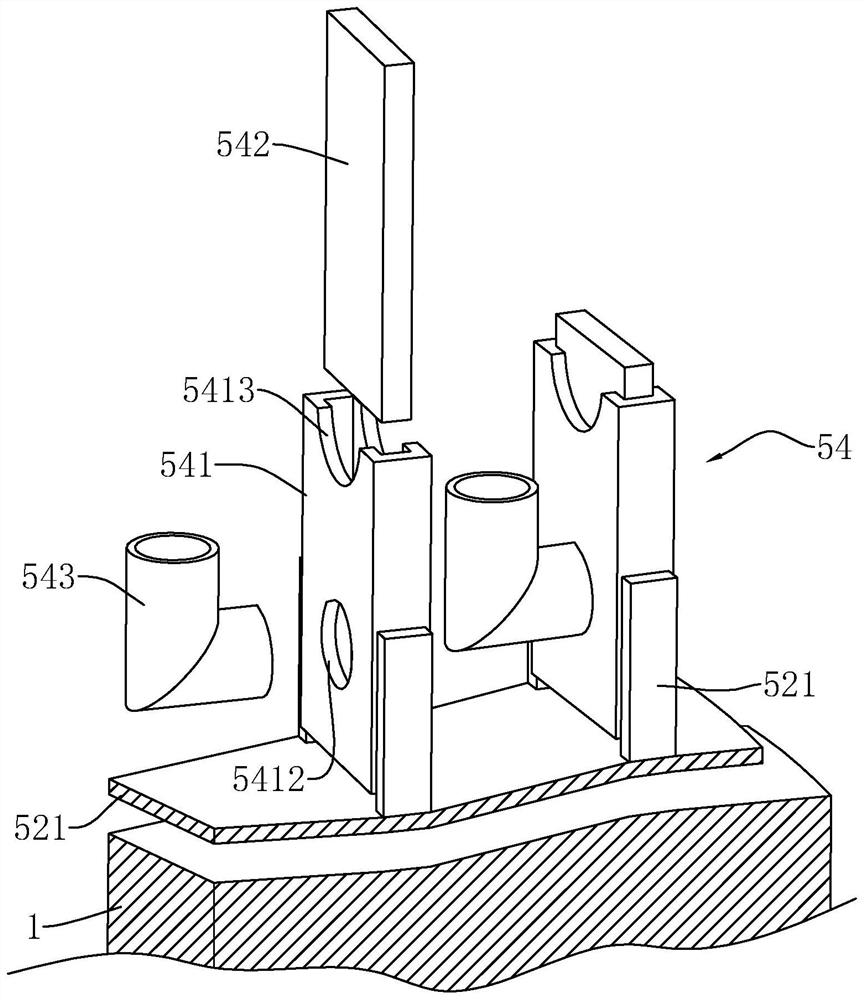

[0064] Such as image 3 As shown, an all-in-one cell production and staining machine includes a workbench 1 and a safety cover 2 hinged on the workbench 1 at one end. When the safety cover 2 is closed, it is fastened with the workbench 1 to form a space. A sample storage mechanism 3 , a pipetting mechanism 4 , a centrifugal mechanism 5 , and a dyeing mechanism 7 are distributed on the surface of the workbench 1 in this space.

[0065] Firstly, the prepared cell suspensions of various samples are placed in the sample storage mechanism 3 . The sample storage mechanism 3 includes a turntable controlled by a motor, and the motor is arranged in the space inside the workbench 1 . The motor is selected as a servo motor, and a number of holding dishes are detachably fixed on the turntable along its circumferential direction, and the holding dishes are used to place the prepared sample cell suspension.

[0066] The centrifugal mechanism 5 includes a centrifugal turntable 52, the cen...

Embodiment 2

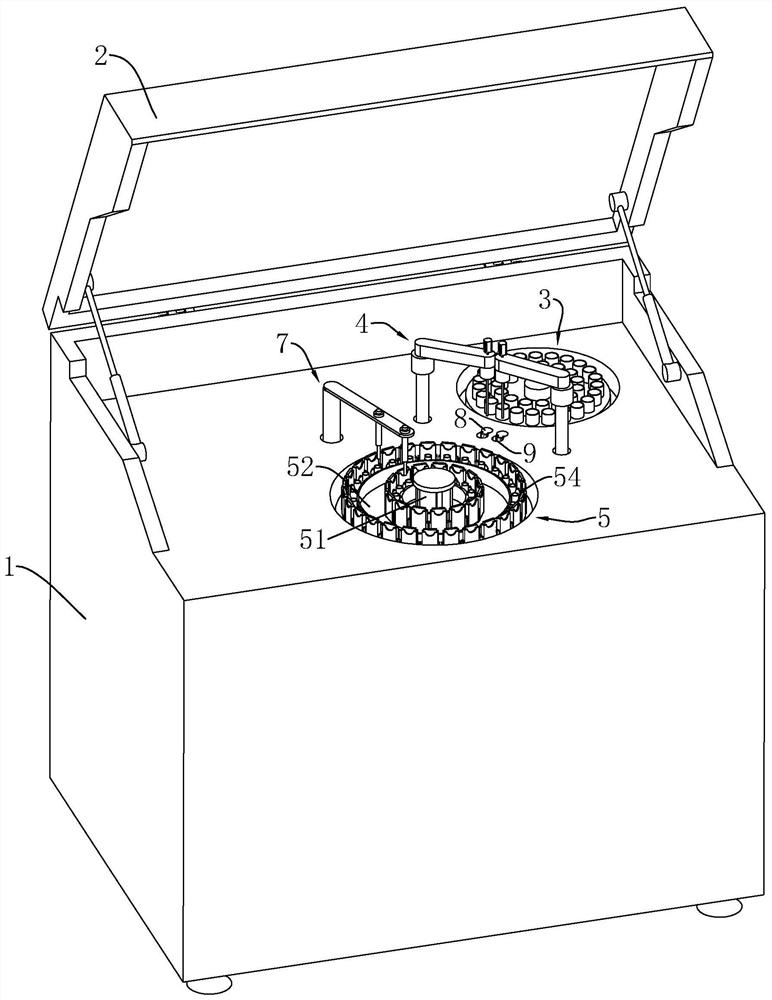

[0095] An all-in-one cell production and staining machine, such as Figure 9 As shown, the pipetting mechanism 4 includes a pipetting needle 43 , and a rotating arm 42 that fixes the pipetting needle 43 and drives the pipetting needle 43 to approach or move away from the workbench 1 . The rotating arm 42 is controlled by the elevating rod 41 stretching out from the workbench 1, and the elevating rod 41 can drive the rotating arm 42 to rotate or lift.

[0096] A cleaning tank 8 and a drying tank 9 are provided on the workbench 1 between the centrifugal mechanism 5 and the waste liquid treatment mechanism 6 .

[0097] combine Figure 11 , There are two pipetting mechanisms 4, and one end of the two pipetting mechanisms 4 fixing the pipetting needle 43 is arranged oppositely. The cleaning tank 8 and the drying tank 9 are arranged on the rotation path of the pipetting needle 43 . After one pipetting is completed, the lifting rod 41 controls the rotating arm 42 to rotate to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com