Identification Method of Stator Resistance Parameters of Induction Motor Based on emd-elm

A technology for stator resistance and induction motors, which is applied to the control of generators, motor generators, and electronically commutated motors. The effect of strong generalization ability, recognition speed and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

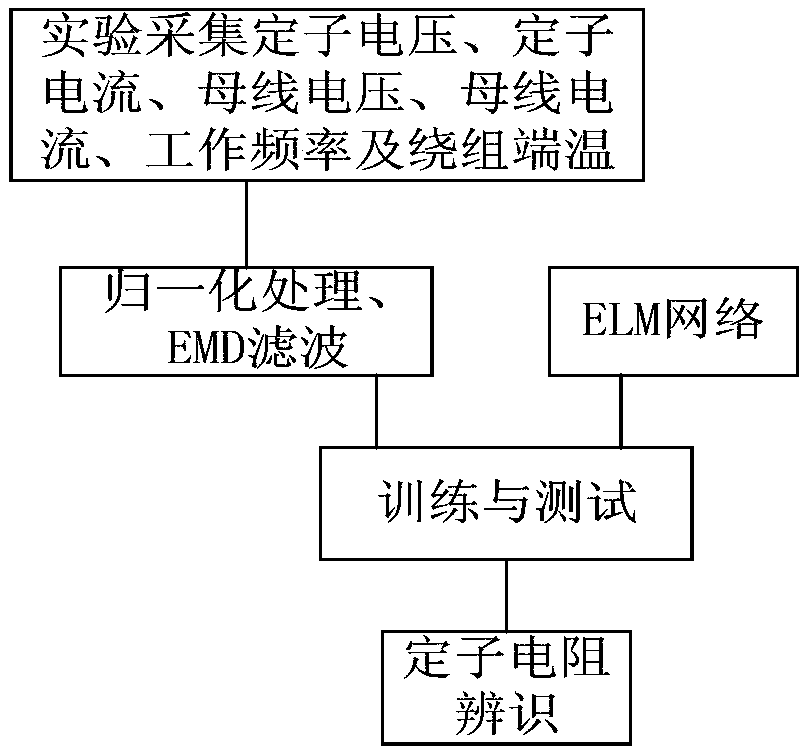

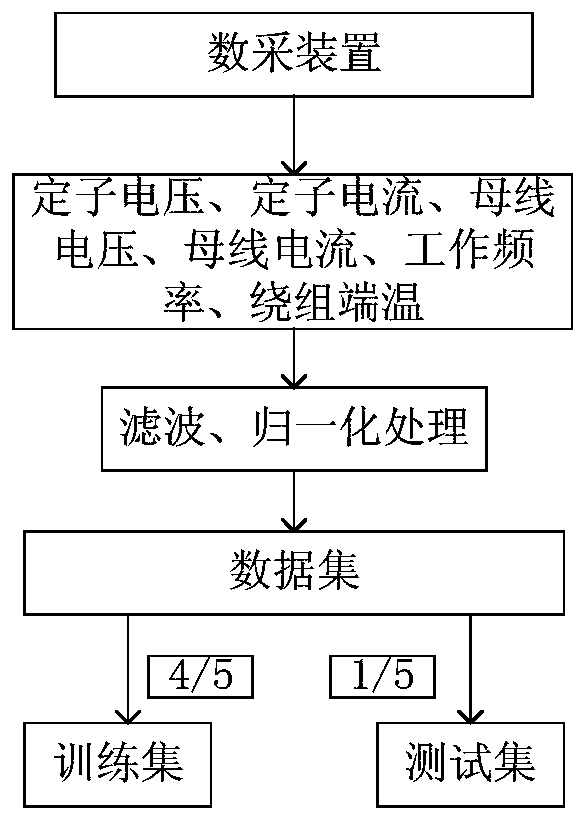

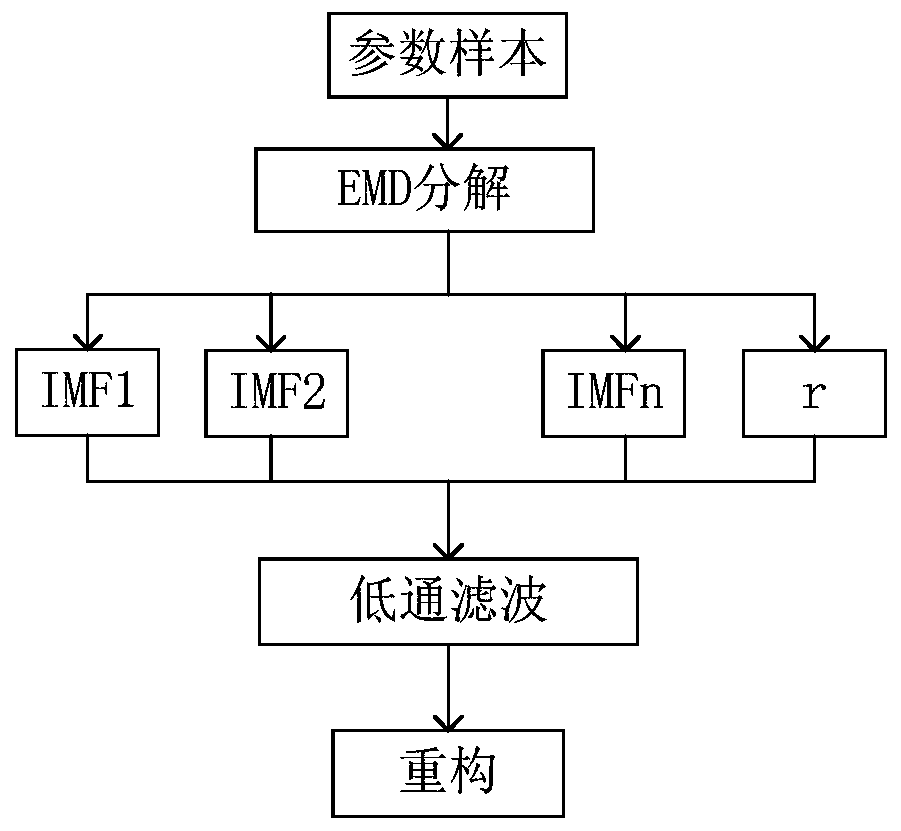

[0078] In this embodiment, the method for identifying the stator resistance parameters of an induction motor based on ELM, the process is as follows figure 1 shown, including the following steps:

[0079] (1) Data collection

[0080] To build a data acquisition platform, the model of the selected induction motor is Y355M2-6. The magnetic powder dynamometer of the model ZF50WKB is used to provide a stable load for the induction motor, and the temperature sensor with a range of 0°C-120°C is used to collect the temperature in real time. Among them, a total of three temperature sensors are evenly embedded in the stator winding. The working frequency is given by the control program and read by the dynamometer; the winding terminal temperature is read by the temperature sensor, the stator voltage and stator current are respectively measured by the voltage and current transformers, the bus voltage and the bus current are measured by the differential in the control circuit The circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com