Current sampling circuit of frequency conversion motor and frequency conversion device

A current sampling, variable frequency motor technology, applied in the direction of AC motor control, estimation/correction of motor parameters, electrical components, etc., can solve the problems of high cost and complex design of variable frequency drive boards, saving design costs and solving complex designs. , the effect of simplifying circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

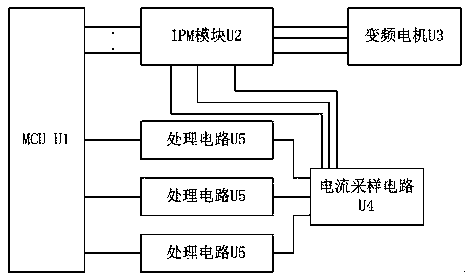

[0018] Such as figure 1 As shown, the variable frequency motor circuit sampling circuit proposed by the present application includes MCU U1, IPM module U2, variable frequency motor U3 and current sampling circuit U4; MCU U1 is connected to IPM module U2 for outputting control signals to IPM module U2; IPM module U2 Connect the variable frequency motor U3 to provide the variable frequency motor U3 with three-phase power to drive its work; the current sampling circuit U4 is connected to the three-phase power output of the IPM module U2 to collect the working current of the three-phase power, that is, the frequency of the variable frequency motor U3 Operating current; also includes processing circuit U5.

[0019] Usually, the MCU U1 controls 6 control signals to the IPM module U2, and the 6 switching devices inside the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com