Fruit picking robot for fruit trees

A technology for picking robots and fruits, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of high labor intensity, falling, increasing labor costs, etc., to reduce labor volume and labor intensity, and reduce storage height. , the effect of smooth picking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

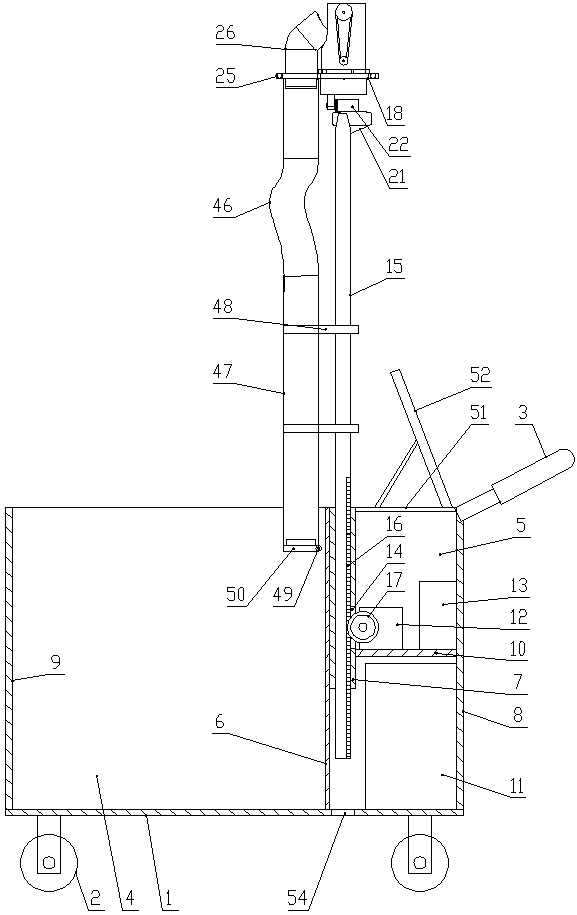

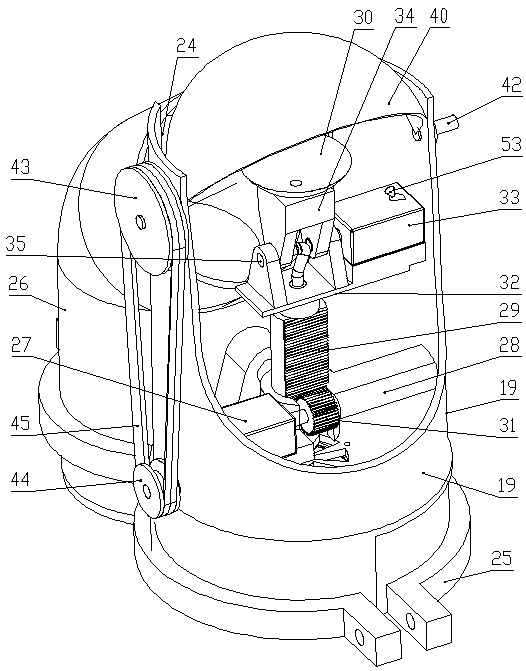

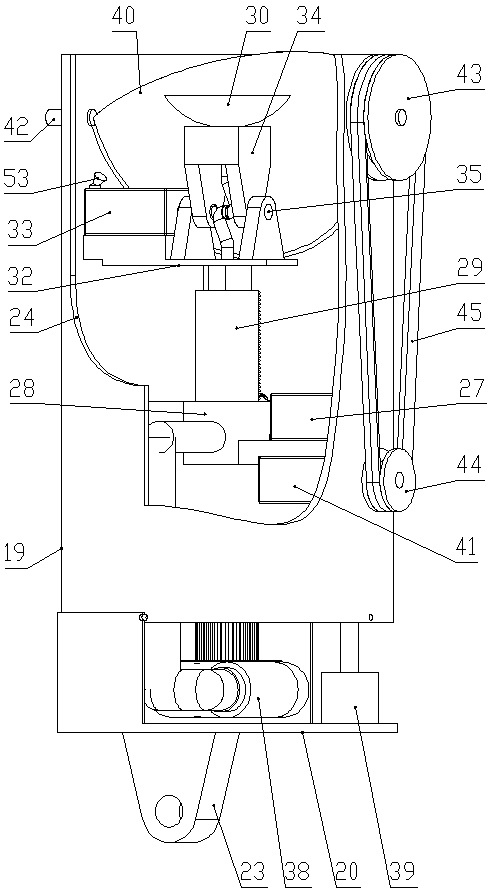

[0025] Such as Figure 1-Figure 4Shown, fruit tree fruit picking robot of the present invention comprises compartment 1, and compartment 1 bottom is provided with wheel 2, and compartment 1 rear side upper part is provided with hand-held push-pull frame 3, and compartment 1 is provided with along vertical direction to divide compartment 1 interior into The vertical dividing plate 6 of front fruit storage chamber 4 and rear driving cavity 5, vertical dividing plate 6 rear sidewalls are fixedly provided with the guiding square pipe 7 that is positioned at rear driving cavity 5 along vertical direction, compartment 1 rear sidewall is provided with The rear door body 8, the front side wall of the compartment 1 is provided with a front door body 9, a horizontal partition 10 is horizontally arranged in the rear drive chamber 5, and a rechargeable battery located under the horizontal partition 10 and on the rear side of the square tube is arranged in the rear drive chamber 5. The bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com