Raking type low-loss pickup

A technology of pickers and elastic teeth, which is applied to harvesting platforms, loaders, and the chassis of agricultural machinery, etc., can solve the problems of picking up shattering loss, loss, and large impact of grain spreading, so as to reduce shattering loss and ground profiling Good ability, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner will be further described below.

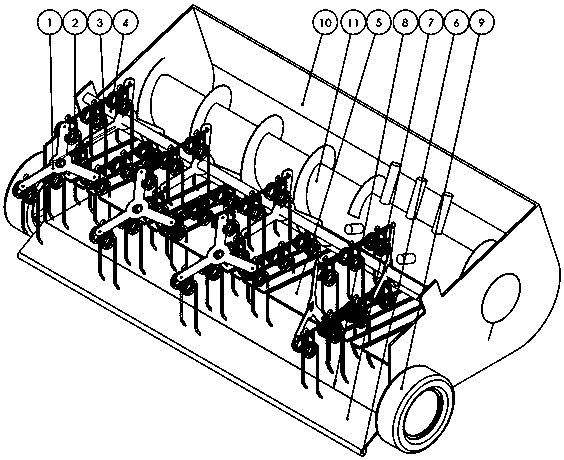

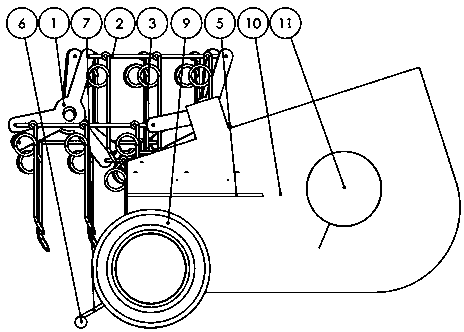

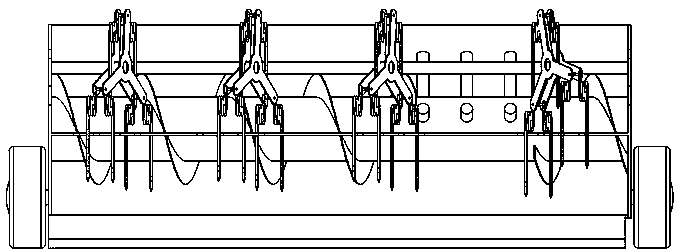

[0019] The pick-up device ( Figure 5 ): The elastic teeth (3) are arranged in parallel rows on both sides of the elastic tooth fixing frame (2), installed between the two discs (1), realize the rotary motion through the transmission shaft (4) and fix it on the header; The pressure plate (5) is fixed on the extension plate of the header, and is located at the highest position of the spring tooth (3) when inserting the grain shop. When the spring tooth rotates and rises, it can prevent the entrainment and winding of the grain shop under the action of the pressure plate; the transmission mechanism (4) uses Universal joint or bevel gear for angular transmission; in the traveling device, profiling wheels (9) are arranged on both sides of the front end of the header to profile the ground, and the front profiling plate (7) is connected to the front end of the header by a torsion spring (8) , to realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com