Rotary fluid machinery

A technology of fluid machinery and rotation phase difference, which is applied in the direction of rotary piston machines, mechanical equipment, rotary piston pumps, etc., can solve the problems of restricting the design freedom of the high pressure port 58, the influence of high efficiency maintenance, and the reduction of compression efficiency, etc., to achieve Securing the degree of freedom in design, suppressing the increase of useless space, and avoiding the effect of increasing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

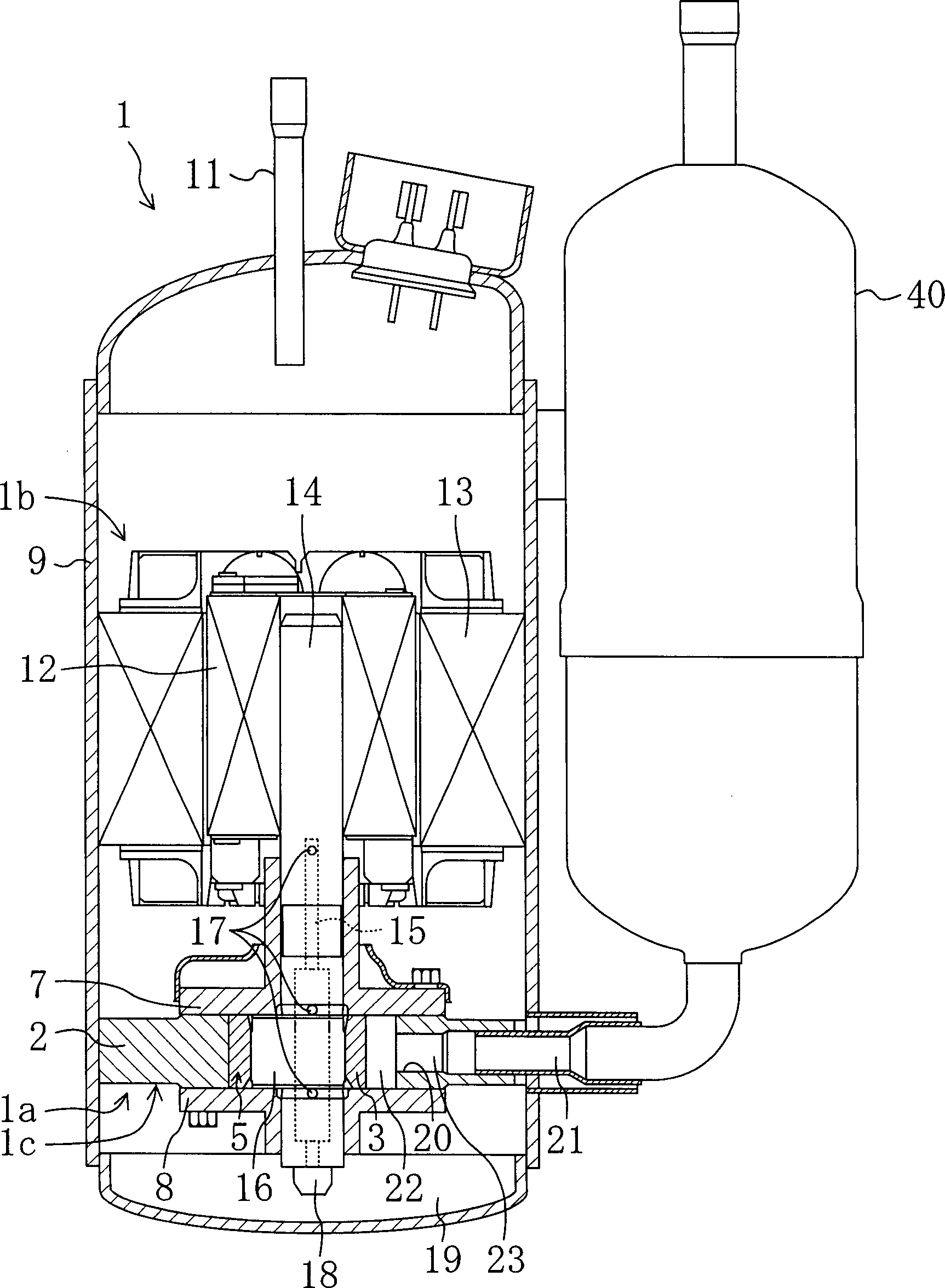

[0045] Such as figure 1 As shown, the rotary fluid machine according to the first embodiment of the present invention is composed of, for example, a rotary compressor 1 installed in a refrigeration device (not shown), and a compression mechanism 1a is accommodated in a hermetic container 9 and a compressor for driving the rotary compressor 1 is provided. Drive mechanism 1b for compression mechanism 1a.

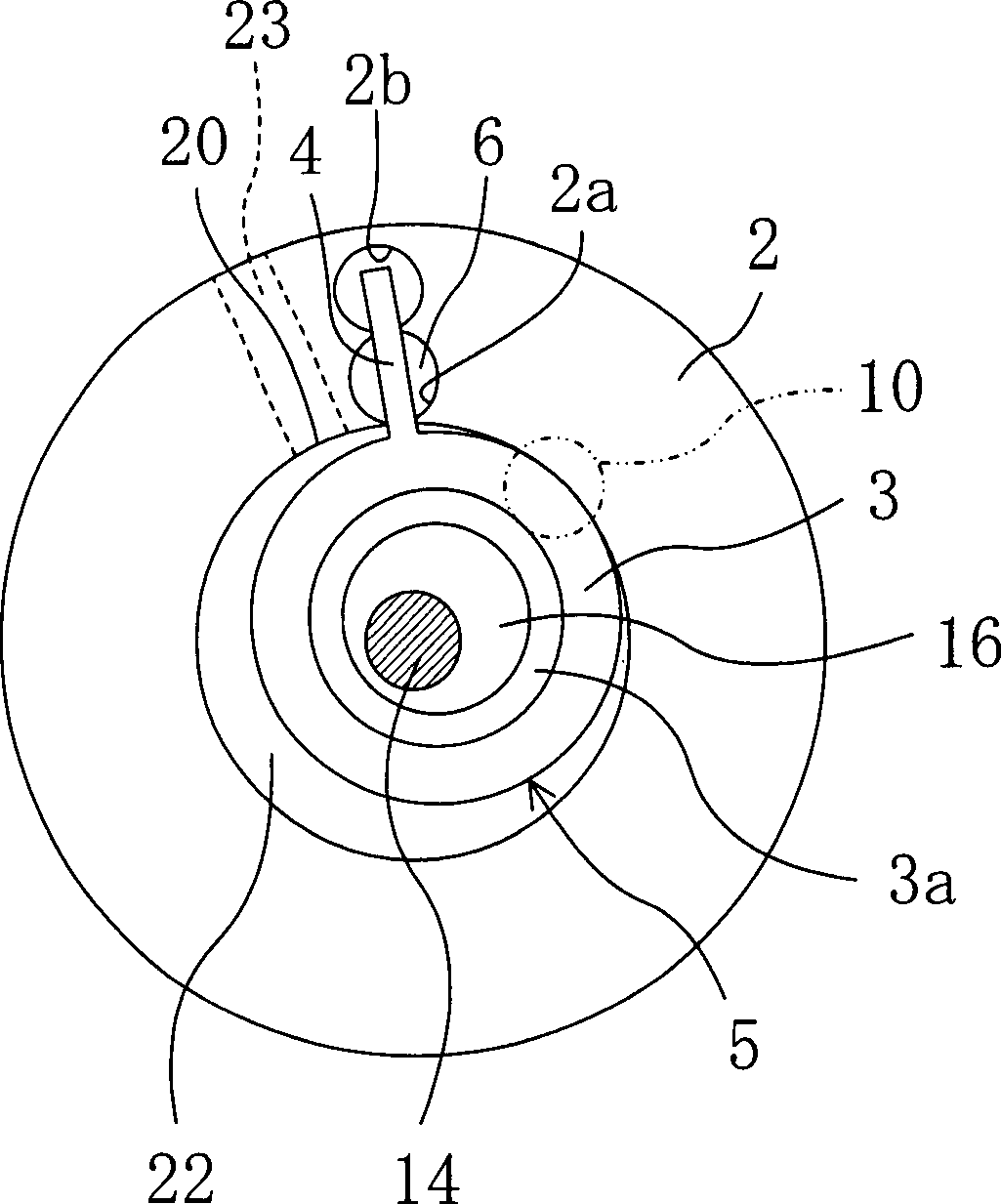

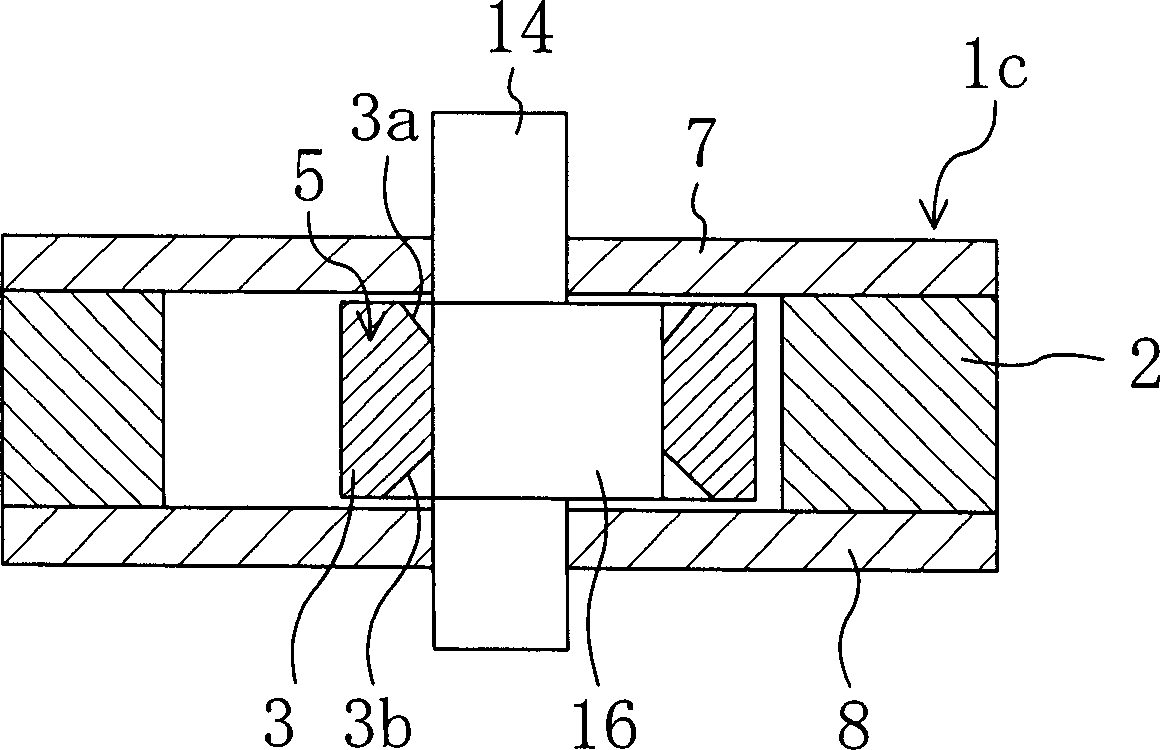

[0046] Such as figure 2 and image 3 As shown, the compression mechanism 1a includes a cylinder 1c and a piston 5 accommodated in the cylinder 1c. The cylinder 1 c includes a cylindrical cylinder body 2 , and a front head 7 and a rear head 8 as plates provided at both upper and lower ends of the cylinder body 2 .

[0047] The piston 5 is provided in the cylinder body 2 and is formed by integrally forming a cylindrical roller 3 and a flat blade 4 extending radially outward from the roller 3 . The piston 5 is made of sintered alloy. That is, in the first embodiment, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com