Jasmine-flower milk tea and preparation method thereof

A technology of jasmine tea and milk tea, which is applied to milk preparations, dairy products, tea treatment before extraction, etc. It can solve the problems of less milk tea flavor choices, thin product taste, and uncoordinated aroma, and achieve a clear tea feeling and prominent characteristic aroma , full-bodied and coordinated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

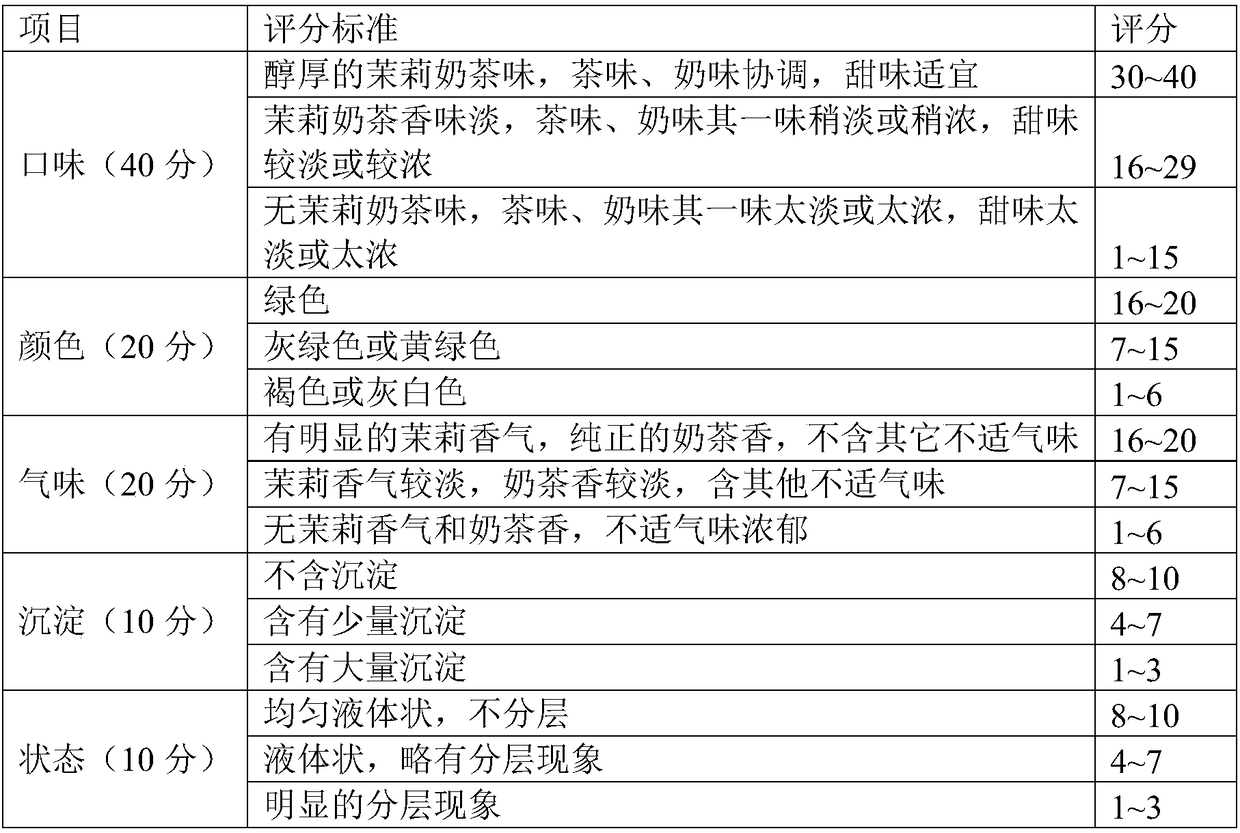

Examples

Embodiment 1

[0049] (1) Take jasmine tea and add it to an airtight extractor for extraction, the water temperature in the airtight extractor is 70°C, the extraction time is 25 minutes, the weight ratio of the tea and water is 1:35, and the jasmine tea extract is filtered, cooled, centrifuge, reserve;

[0050] (2) Add sugars and 50% acidity regulator to 4Kg water at 50°C to obtain preparation A; filter and sterilize;

[0051] (3) Add matcha, color-protecting agent (zinc gluconate) and the remaining acidity regulator into 2Kg of 15°C water to obtain preparation solution B;

[0052] (4) Add a stabilizer to the water at a temperature of 79°C, stir and shear, when the water temperature reaches 70°C, add milk, emulsifier and antioxidant in proportion, stir, add the preparation solution B prepared in step (3), stir, Get the milk tea base liquid; put it into the homogenizer, wherein the low pressure is 40Bar, the high pressure is 200Bar, and the temperature is 75°C

[0053] (5) Mix the jasmine t...

Embodiment 2

[0056] (1) Take jasmine tea and add it to an airtight extractor for extraction. The water temperature in the airtight extractor is 75° C., and the extraction time is 15 minutes. The weight ratio of the tea and water is 1:50, and the jasmine tea extract is filtered, cooled, and centrifuge, reserve;

[0057] (2) Add sugars and 40% acidity regulator to 5Kg water at 52°C to obtain preparation A; filter and sterilize;

[0058] (3) Add matcha, color-protecting agent (zinc gluconate) and the remaining acidity regulator into 2Kg of 20°C water to obtain preparation B;

[0059] (4) Add a stabilizer to water at a temperature of 80°C, stir and shear, when the water temperature reaches 68°C, add milk, emulsifier and antioxidant in proportion, stir, add the preparation solution B prepared in step (3), stir, Get the milk tea base liquid; put it into the homogenizer, wherein the low pressure is 30Bar, the high pressure is 180Bar, and the temperature is 65°C

[0060] (5) Mix the jasmine tea ...

Embodiment 3

[0063] (1) Take jasmine tea and add it to an airtight extractor for extraction. The water temperature in the airtight extractor is 72° C., and the extraction time is 20 minutes. The weight ratio of the tea to water is 1:40, and the jasmine tea extract is filtered, cooled, and centrifuge, reserve;

[0064] (2) Add sugars and 20% acidity regulator to 5kg of 60°C water to obtain preparation A; filter and sterilize;

[0065] (3) Add matcha, color-protecting agent (zinc gluconate) and the remaining acidity regulator into 6kg of water at 25°C to obtain preparation solution B;

[0066] (4) Add a stabilizer to the water at a temperature of 85°C, stir and shear, when the water temperature reaches 75°C, add milk, emulsifier and antioxidant in proportion, stir, add the preparation solution B prepared in step (3), stir, Get the milk tea base liquid; put it into the homogenizer, wherein the low pressure is 30Bar, the high pressure is 190Bar, and the temperature is 72°C

[0067] (5) Mix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com