Liquid-washing all-dimensional homogenous agitating kettle

A homogeneous stirring, all-round technology, applied in mixer accessories, mixers with rotary stirring devices, chemical instruments and methods, etc., can solve the problems of uneven mixing, uneven product quality, uneven mixing of raw materials at the edge, etc. To achieve the effect of full stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the embodiments and the accompanying drawings.

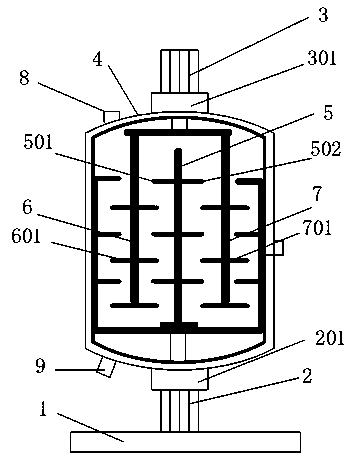

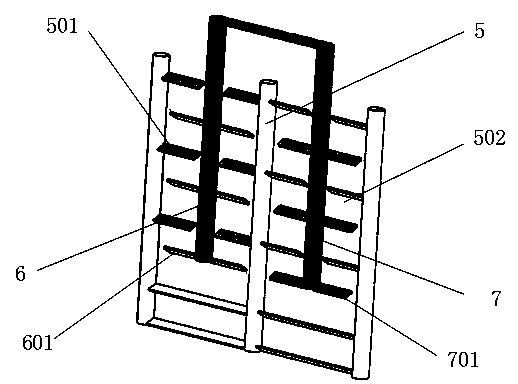

[0017] Such as figure 1 As shown, a liquid washing all-round homogeneous stirring pot includes: a base 1, a first motor 2, a first motor base 201, a second motor 3, a second motor base 301, a stirring pot 4, a main shaft 5, a main Shaft stirring blade 501 , first auxiliary rotating shaft 6 , first auxiliary stirring blade 601 , second auxiliary rotating shaft 7 , second auxiliary stirring blade 701 , feed inlet 8 , and discharge outlet 9 .

[0018] The base 1 is provided with a first motor 2 and a first motor base 201 , the stirring pot 4 is fixed by a fixed bracket, and the top of the stirring pot 4 is provided with a second motor 3 and a second motor base 301 .

[0019] The output shaft of the first motor 2 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com