Flotation machine transmission device

A transmission device and flotation machine technology, applied in flotation, solid separation, etc., can solve problems such as grease failure, high-power input structure actual operation difficulties, affecting the service life of the transmission structure and maintenance costs, etc., to reduce maintenance, The effect of large power input and reduced downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

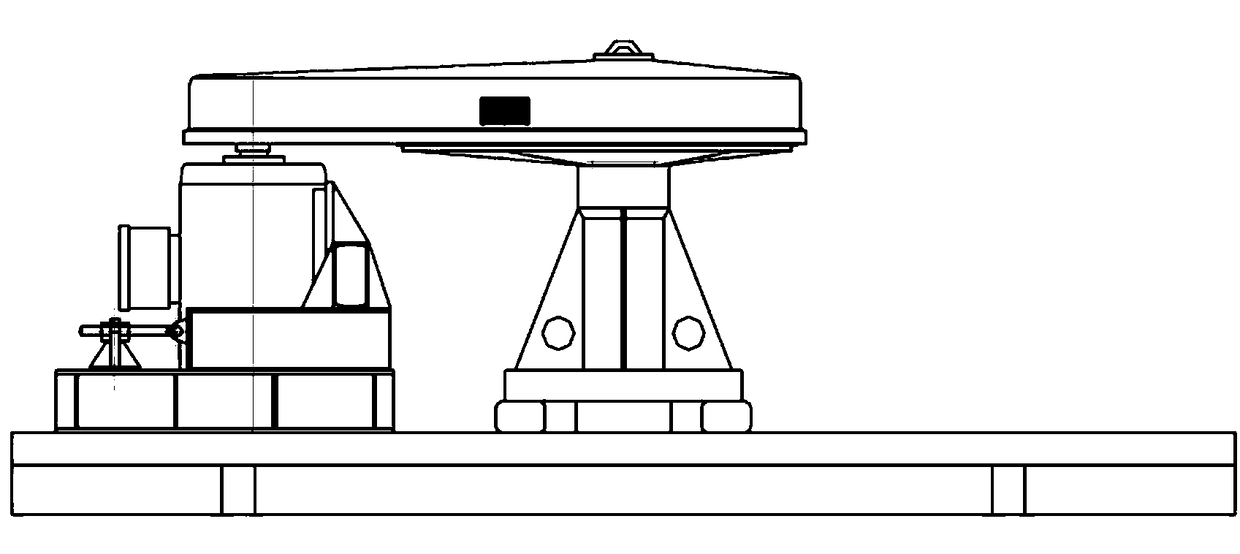

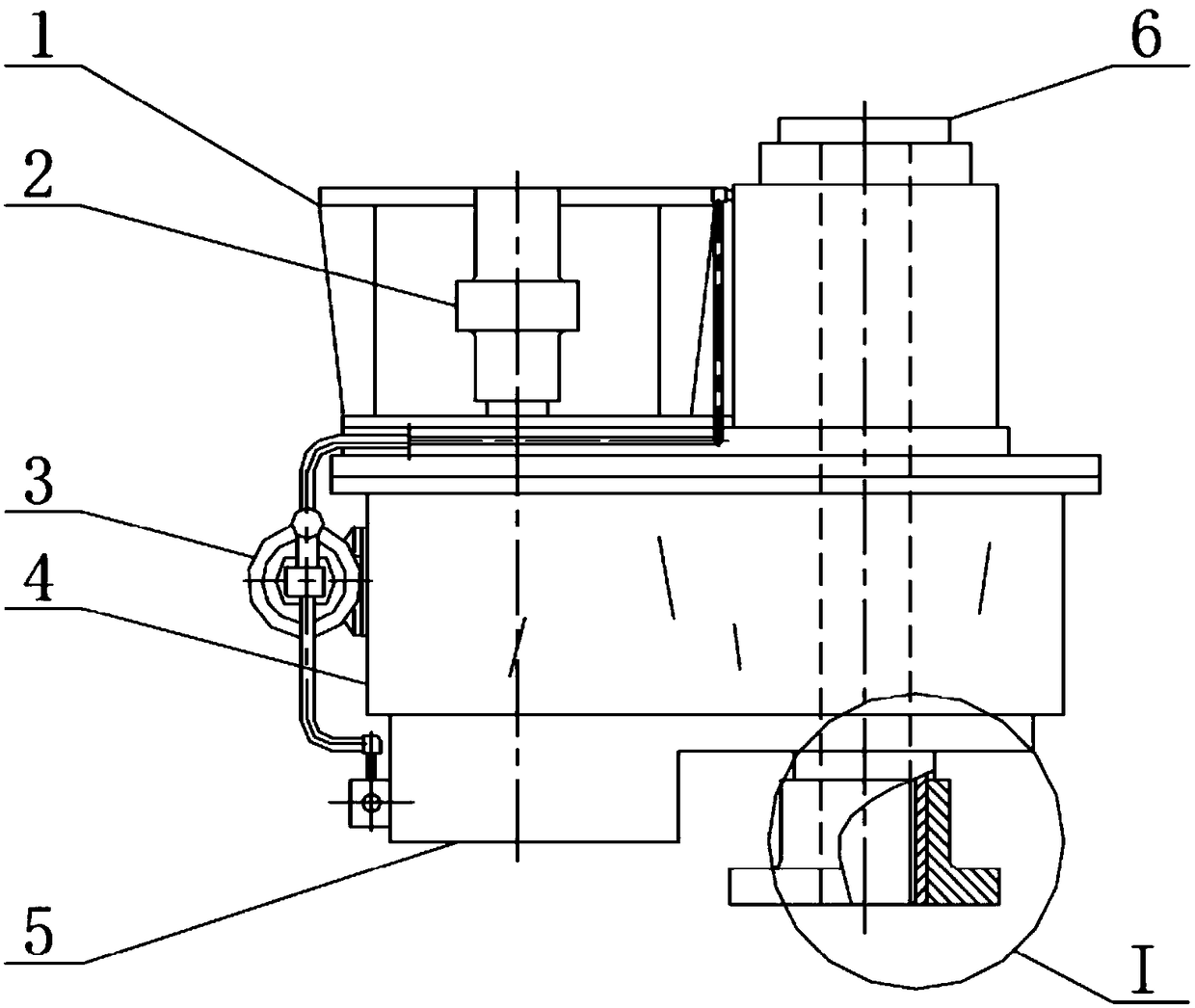

[0023] Flotation machine transmission device of the present invention, its preferred embodiment is:

[0024] Including reduction box, upper hollow shaft, motor support frame, auxiliary oil tank and lubricating oil circulation pump;

[0025] The upper hollow shaft is installed in the reduction box body and serves as the output shaft of the reduction box body, the motor bracket is arranged on the upper part of the reduction box body, and the input shaft of the reduction box body is connected with the high speed end coupling The motor shaft is connected and parallel to the upper hollow shaft.

[0026] The upper hollow shaft passes through the reduction box body longitudinally, the upper end of the upper hollow shaft is provided with a compressed air pipe joint, and the lower end is provided with a lower shaft connection flange.

[0027] A vacuum insulation layer is provided on the inner wall of the upper hollow shaft.

[0028] The lower part of the reduction box body is provide...

specific Embodiment

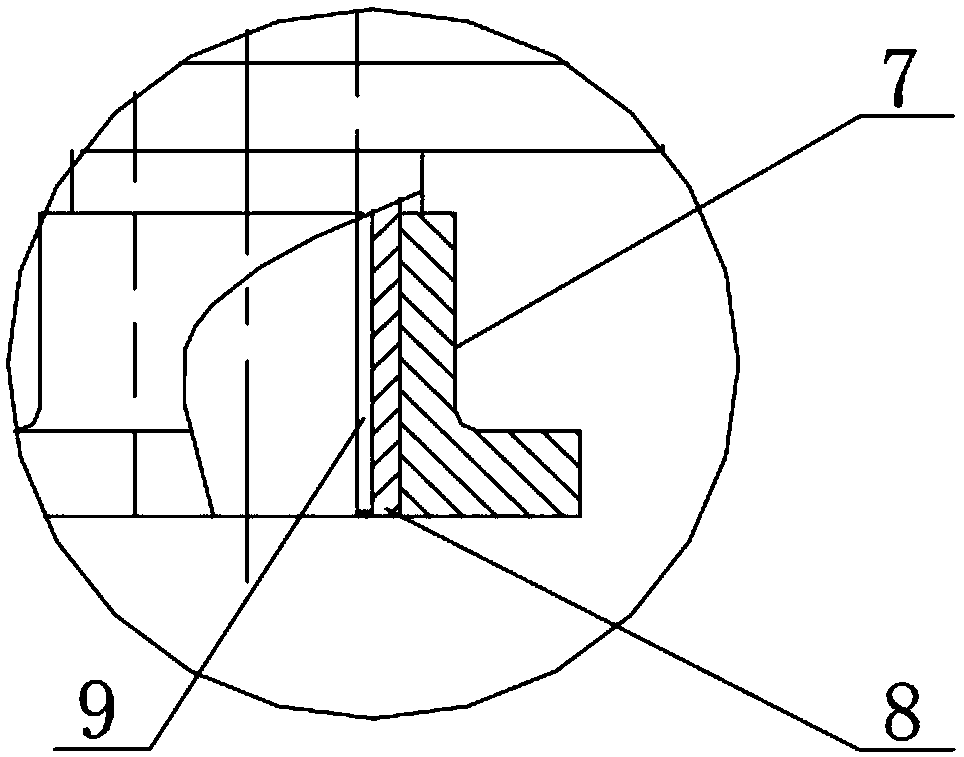

[0031] Such as Figure 2 to Figure 4 As shown, the driving motor is installed vertically downward on the motor bracket 1 through the flange, and the output shaft of the motor is connected to the input end of the high-speed shaft of the transmission device through the coupling 2; the reduction box body 4 is equipped with multi-stage reduction gears and the upper hollow shaft 8. A compressed air pipe joint 6 is provided at the upper end of the upper hollow shaft, and a flange 7 connected to the lower shaft is provided at the lower end of the upper hollow shaft 8. For heat insulation, a vacuum insulation layer 9 is provided on the inner wall of the upper hollow shaft The entire transmission device is lubricated with thin oil, and the reduction box body 4 is filled with lubricating thin oil, and an auxiliary oil tank 5 is provided at the bottom of the reduction box body 4. At the upper bearing seat of the box body 4.

[0032] Effect of the present invention:

[0033] The upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com