Robot for spraying production

A technology of robot and robot body, applied in the direction of injection device, etc., can solve the problems of winding, cable clutter, affecting production and operation, etc., to achieve the effect of clean and tidy structure and avoid clutter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

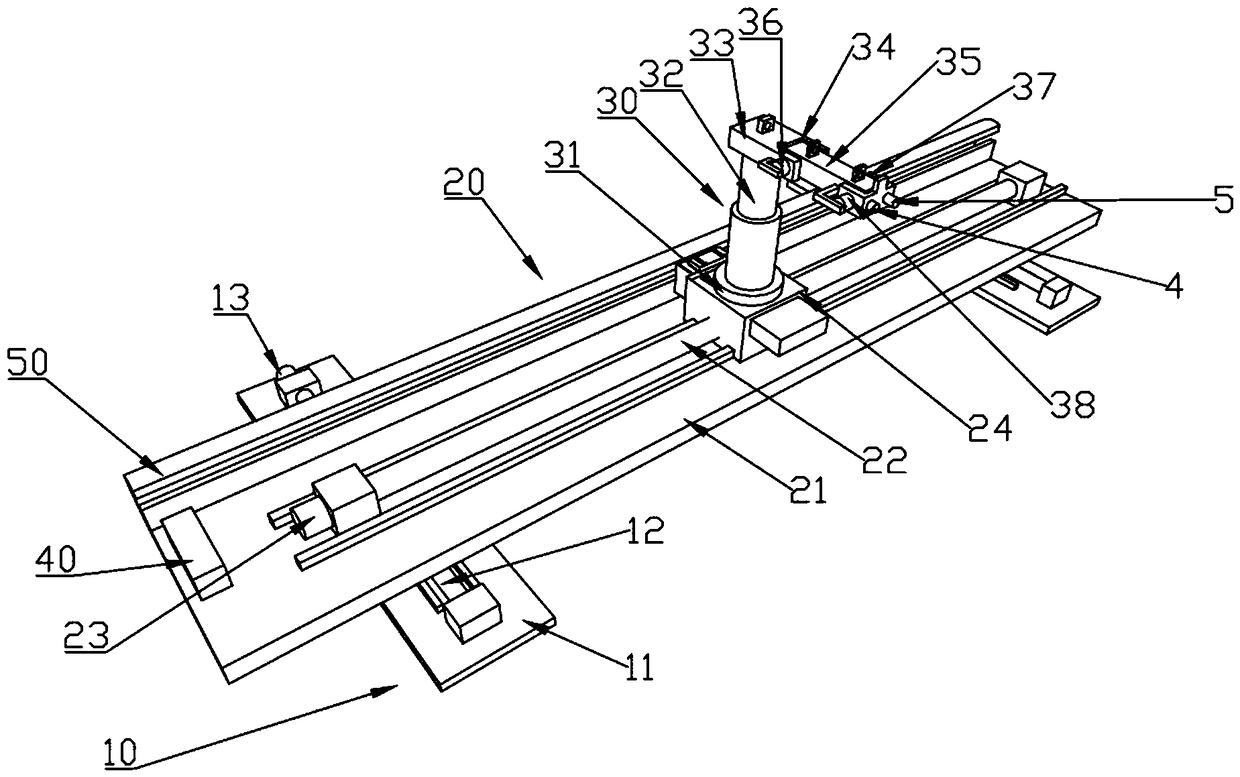

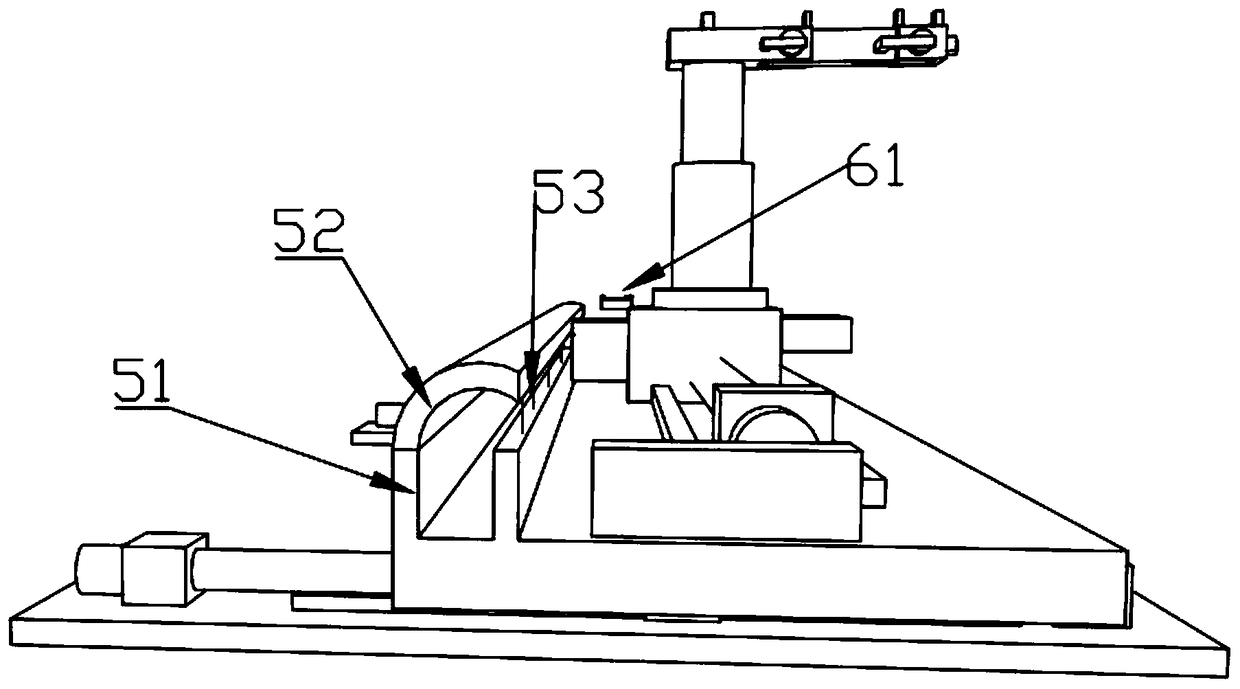

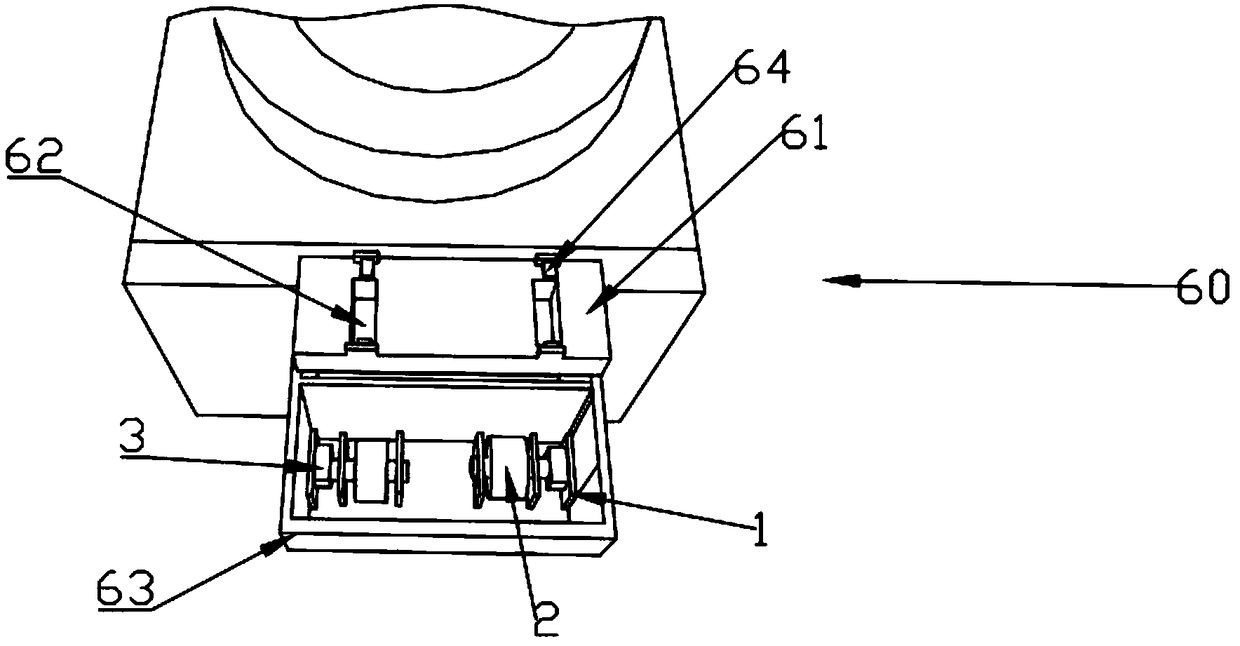

[0019] to combine Figure 1 to Figure 3 A robot for spraying production shown in this embodiment includes two lateral movement assemblies 10, a vertical movement assembly 20, a robot body 30, a PLC controller 40, and a cable finishing groove 50, and the lateral movement assembly 10 includes Two transverse plates 11, the transverse lead screw 12 respectively arranged on the two transverse plates 11, the transverse motor 13 connected to one end of the transverse lead screw 12, the transverse lead screw nut matched with the transverse lead screw 12 and sleeved and fixed on the transverse The horizontal base on the lead screw nut, the vertical movement assembly 20 includes the vertical plate 21 fixed on the two horizontal bases, the vertical screw 22 fixed on the vertical plate 21, the vertical screw connected to one end of the vertical screw 22. Motor 23, the vertical lead screw nut that cooperates with vertical lead screw 22 and the vertical base 24 that is sleeved and fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com