Full-automatic punching machine mold

A fully automatic, stamping die technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of adjusting the height of the punch die body, no springs, no settings, etc., so as to avoid the decline of processing quality and reduce dangerous accidents. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

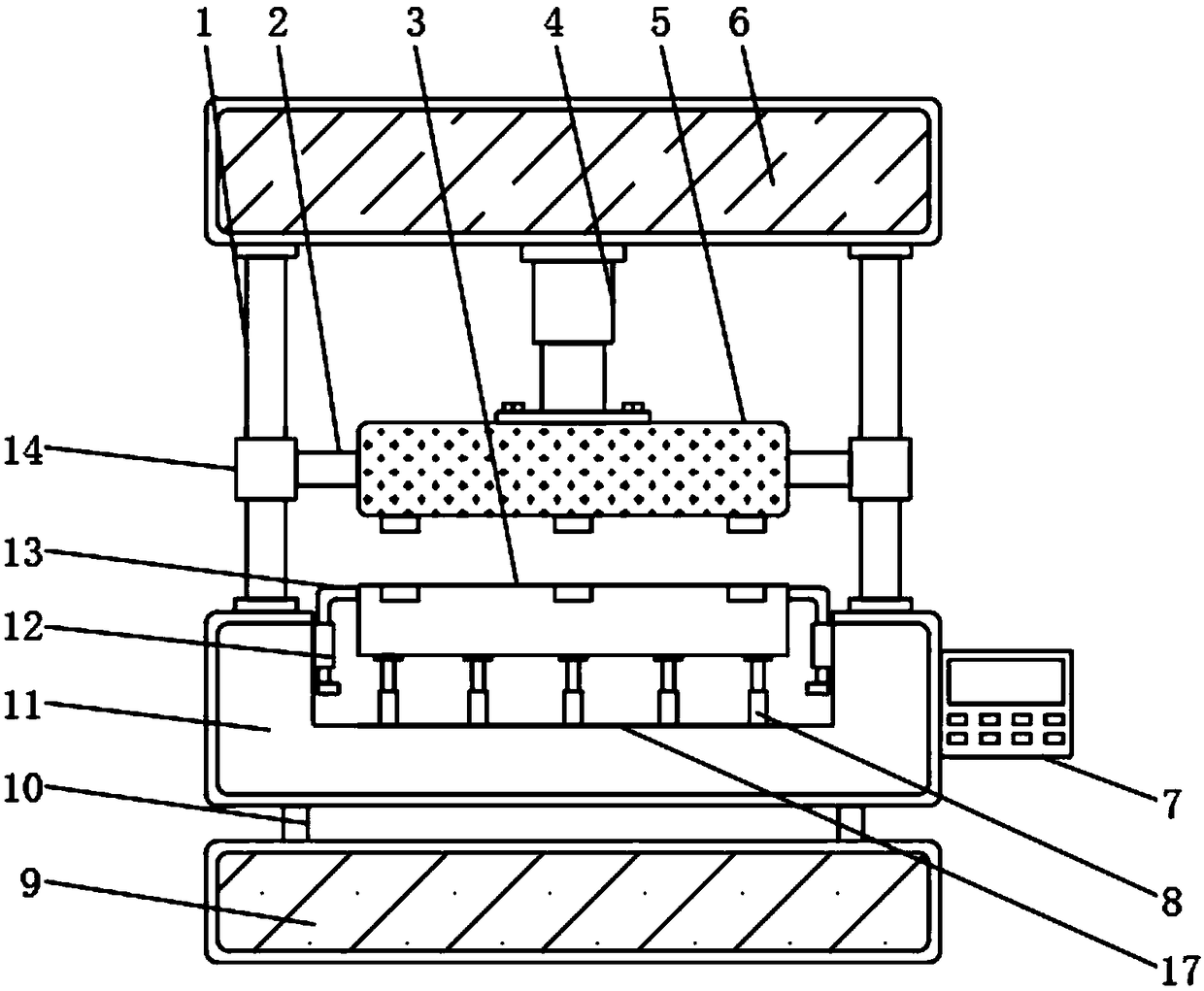

[0020] see Figure 1~3 , the present invention provides a technical solution:

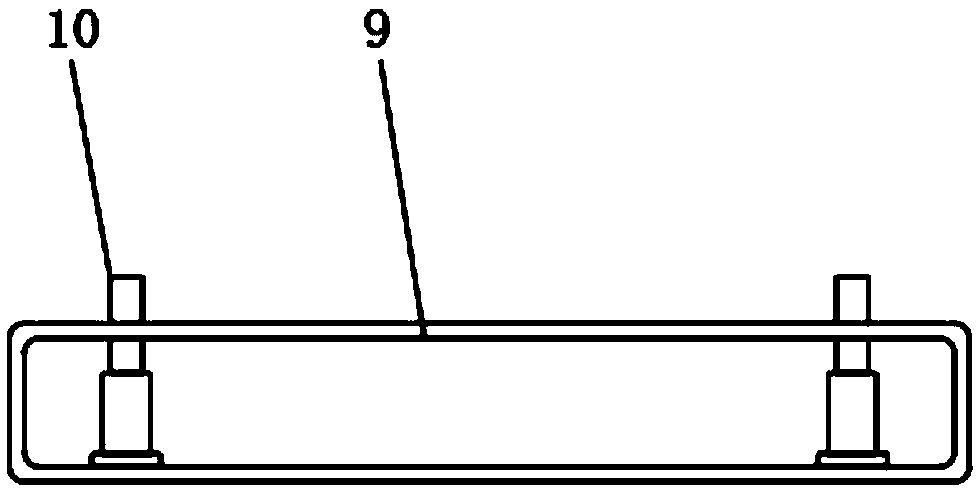

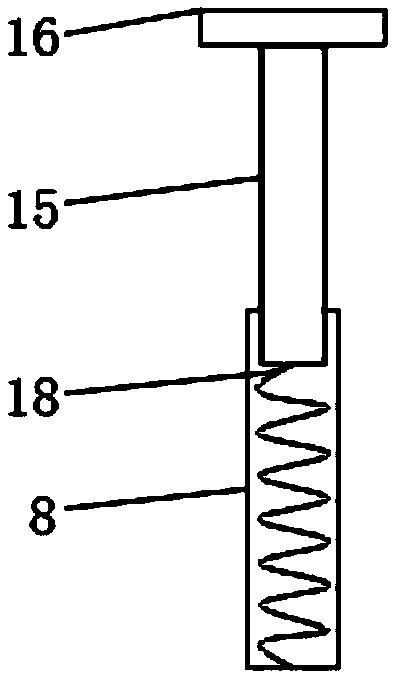

[0021] A fully automatic punching die, comprising a punching die body 11, a hydraulic cylinder 4 and a lower template 3, a control switch 7 is fixedly installed on one side of the punching die body 11, and a slide bar 1 is fixedly installed on the top of the punching die body 11, and the punching The inside of the die body 11 is provided with a groove 17, and the bottom end of the stamping die body 11 is fixedly equipped with an electro-hydraulic push rod 10, the outside of the slide bar 1 is sleeved with a second sleeve 14, and the top end of the slide bar 1 is fixedly installed There is a first support platform 6, a bracket 2 is fixedly installed on one end of the second sleeve 14, and the hydraulic cylinder 4 is fixedly installed on the bottom end of the first support platform 6 near the side of the slide bar 1, and the bottom end of the hydraulic cylinder 4 The upper template 5 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com