Spot welding machine with six-axis robot

A six-axis robot and spot welding machine technology, applied in welding equipment, resistance welding equipment, metal processing equipment and other directions, can solve the problems of high work intensity and low production efficiency, and achieve improved product quality, easy welding, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

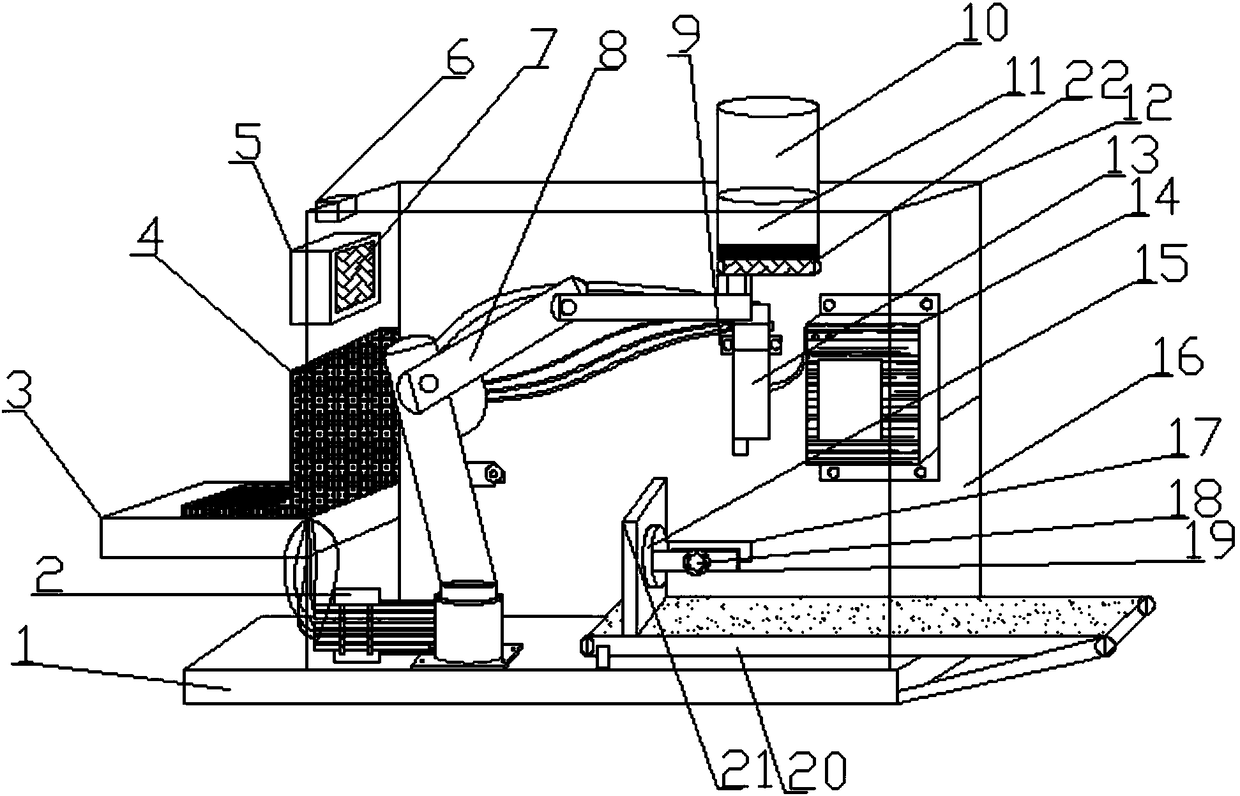

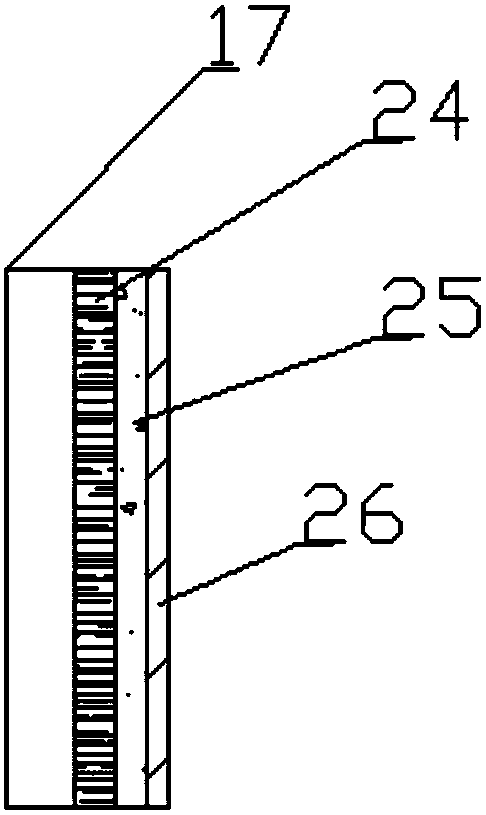

[0022] Such as Figure 1-2 As shown, a spot welding machine with a six-axis robot includes a base 1, a conveyor belt body 20, a six-axis robot body 8 and an automatic electric welding machine main body 14, and the top of the base 1 is equipped with a protective cover 12 by bolts, so One side of the protective cover 12 is provided with a placement platform 3 through a mounting piece, and the upper end of the placement platform 3 is provided with an air inlet 5, and a small cooling fan 7 is installed through a mounting seat in the air inlet 5, and the protective cover 12 The other side is provided with a feed port 16, the conveyor belt body 20 runs through the feed port 16, and one end of the top of the conveyor belt body 20 is equipped with a mounting plate 21 through a bolt, and one side of the mounting plate 21 is provided with an electric motor through a screw. Turntable 15, one side of the electric turntable 15 is provided with a limit clamp 17 through a fixing member, a fi...

Embodiment 2

[0038] Such as Figure 1-2 As shown, a spot welding machine with a six-axis robot includes a base 1, a conveyor belt body 20, a six-axis robot body 8 and an automatic electric welding machine main body 14, and the top of the base 1 is equipped with a protective cover 12 by bolts, so One side of the protective cover 12 is provided with a placement platform 3 through a mounting piece, and the upper end of the placement platform 3 is provided with an air inlet 5, and a small cooling fan 7 is installed through a mounting seat in the air inlet 5, and the protective cover 12 The other side is provided with a feed port 16, the conveyor belt body 20 runs through the feed port 16, and one end of the top of the conveyor belt body 20 is equipped with a mounting plate 21 through a bolt, and one side of the mounting plate 21 is provided with an electric motor through a screw. Turntable 15, one side of the electric turntable 15 is provided with a limit clamp 17 through a fixing member, a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com