Edge grinding machine of precise workpiece

An edging machine and workpiece technology, which is applied in the field of workpiece processing, can solve the problems of inability to grind workpieces with multiple angles, high labor intensity of operators, and low grinding quality, so as to improve the quality of edging, improve work efficiency, and enhance quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

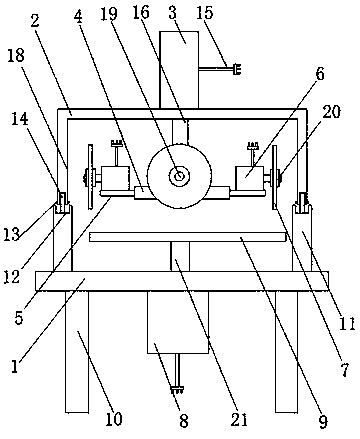

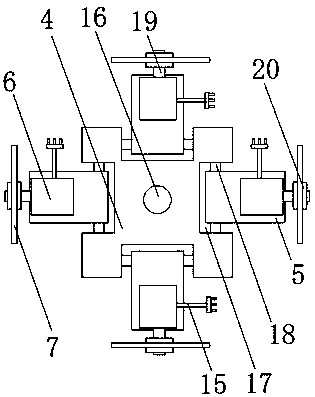

[0016] as attached figure 1 and 2 Shown, a kind of edging machine of precision workpiece, comprises console 1, carrier frame 2, cylinder 3, fixed plate 4, adjusting plate 5, grinding motor 6, edging wheel 7, motor 2 8 and bearing plate 9, its The feature is that the console 1 is set on the bracket 10, a vertical plate 11 is provided on the console 1, and a limiting groove 12 is provided on the vertical plate 11, and the carrier frame 2 is provided with a connecting shaft 13 There are road wheels 14, and the road wheels 14 are arranged in the limit groove 12, the cylinder 3 is arranged on the carrier frame 2, and the cylinder 3 is provided with a power cord 15, a piston rod 16, and the fixed plate 4 is arranged on the piston rod 16, and a connection groove 17 is arranged on the fixed plate 4, the described adjusting plate 5 is arranged in the connecting groove 17 through the connecting rod 18, and the described grinding motor 6 is arranged on the adjusting plate 5, And be pro...

Embodiment 2

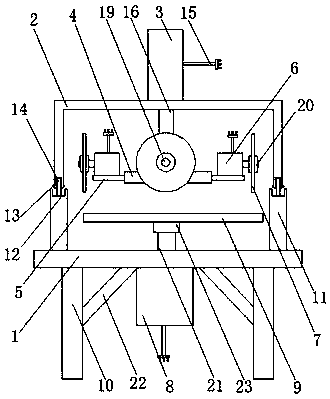

[0021] as attached image 3 Shown, a kind of edging machine of precision workpiece, comprises console 1, carrier frame 2, cylinder 3, fixed plate 4, adjusting plate 5, grinding motor 6, edging wheel 7, motor 2 8 and bearing plate 9, its The feature is that the console 1 is set on the bracket 10, a vertical plate 11 is provided on the console 1, and a limiting groove 12 is provided on the vertical plate 11, and the carrier frame 2 is provided with a connecting shaft 13 There are road wheels 14, and the road wheels 14 are arranged in the limit groove 12, the cylinder 3 is arranged on the carrier frame 2, and the cylinder 3 is provided with a power cord 15, a piston rod 16, and the fixed plate 4 is arranged on the piston rod 16, and a connection groove 17 is arranged on the fixed plate 4, the described adjusting plate 5 is arranged in the connecting groove 17 through the connecting rod 18, and the described grinding motor 6 is arranged on the adjusting plate 5, And be provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com