a polishing device

A polishing device and fixing device technology, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of low polishing efficiency and inability to apply, and achieve good polishing effect, good protection, The effect of pressure averaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with embodiment.

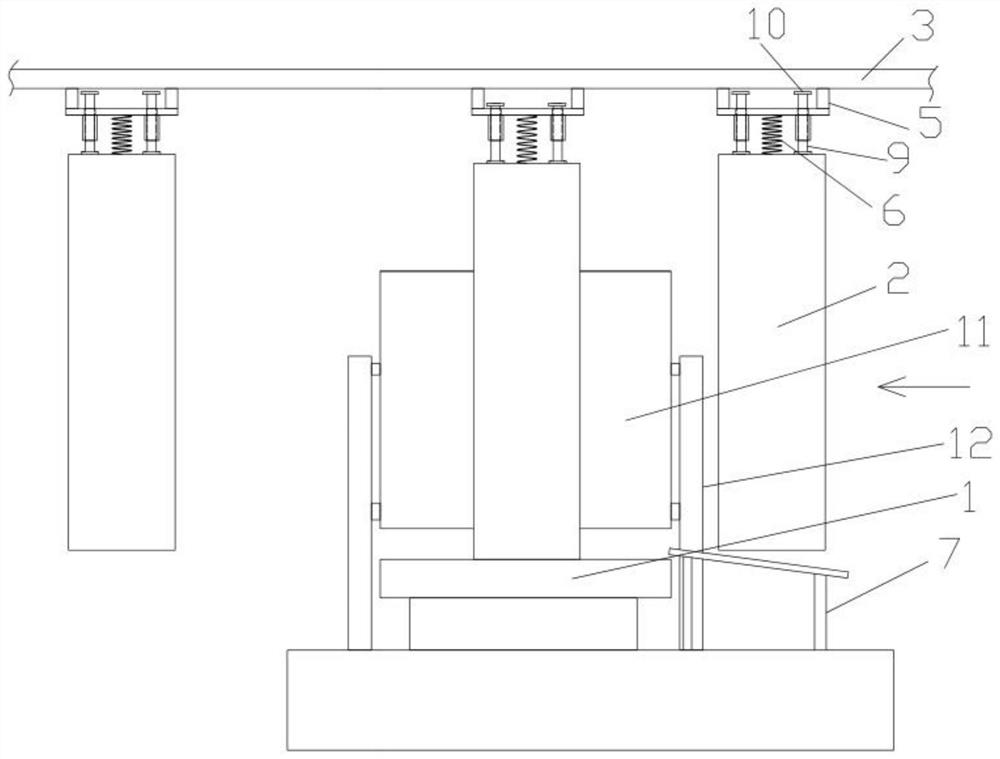

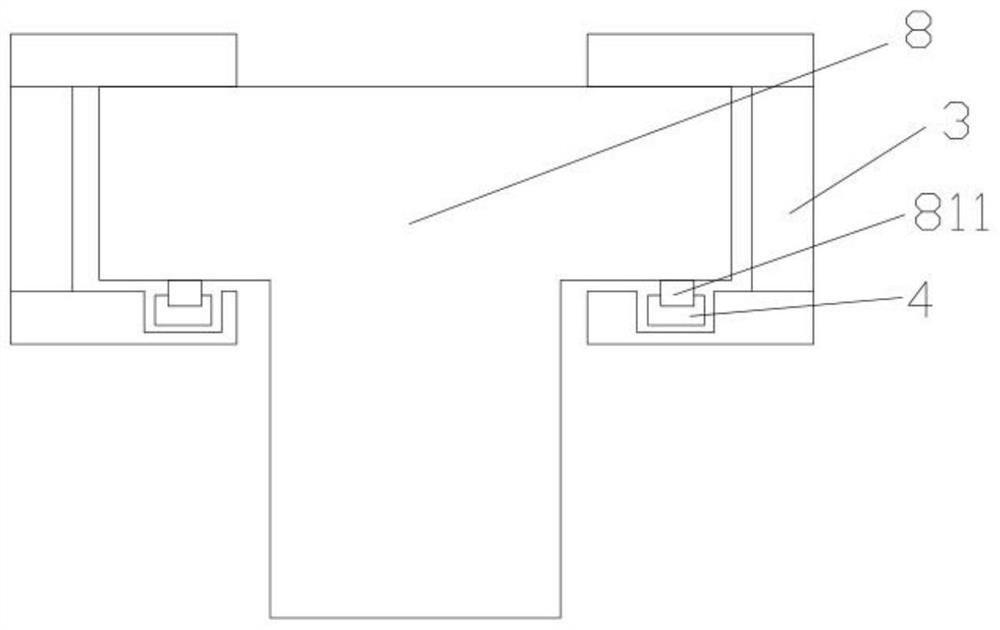

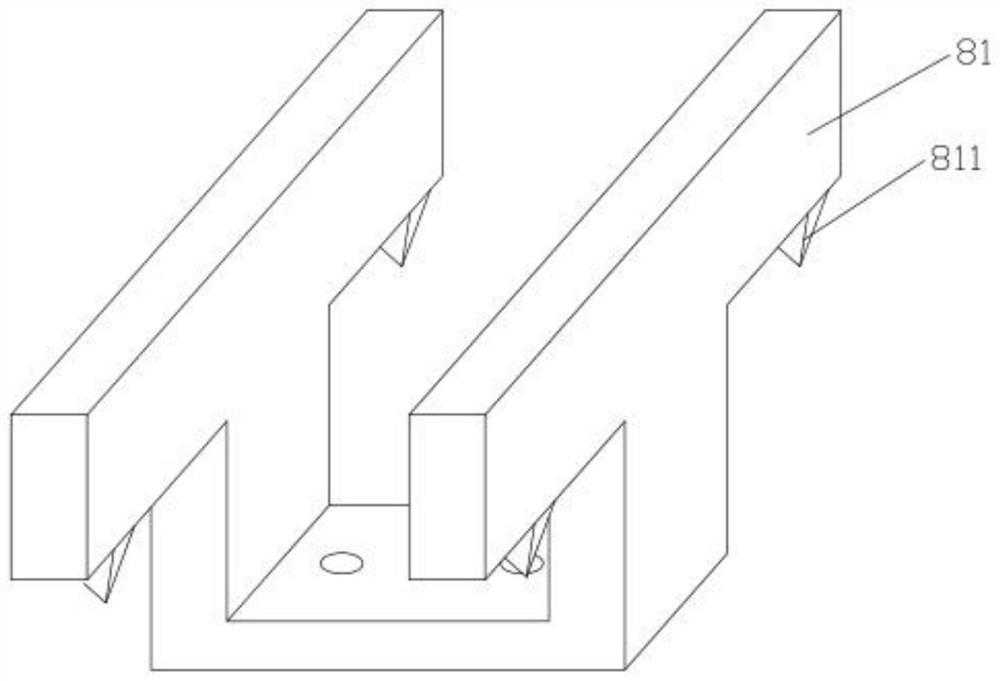

[0015] Such as Figure 1-Figure 3 A kind of polishing device shown, comprises polishing workbench 1, and polishing workbench 1 is the common polishing machine on the market, is provided with the assembly line that conveys workpiece 2 above the polishing workbench 1, channel steel guide rail 3 is set on the assembly line, and The bottom of the channel steel guide rail 3 is preset with a chain 4, the chain 4 is driven by a motor (not shown in the figure), and a workpiece fixing device 5 is arranged on the assembly line, and the upper end of the workpiece 2 is fixed on the workpiece fixing device 5 and moves together with the assembly line , the workpiece fixing device 5 is provided with a pressure device 6 that applies elastic pressure downward to the workpiece, and a bridge device 7 is provided on the feeding side of the polishing workbench 1, and the bridge device is an obliquely arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com