Grinding head device capable of precisely controlling sensing quantity

A precise and controller technology, applied in grinding drives, grinding heads, manufacturing tools, etc., can solve the problems of electric spindle burnout, increased cutting force, and inability to meet the strict requirements of casting shape and size consistency. , to achieve the effect of accurately ensuring the positioning accuracy of the clamping, accurately ensuring the consistency of the size, and being conducive to product quality control management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

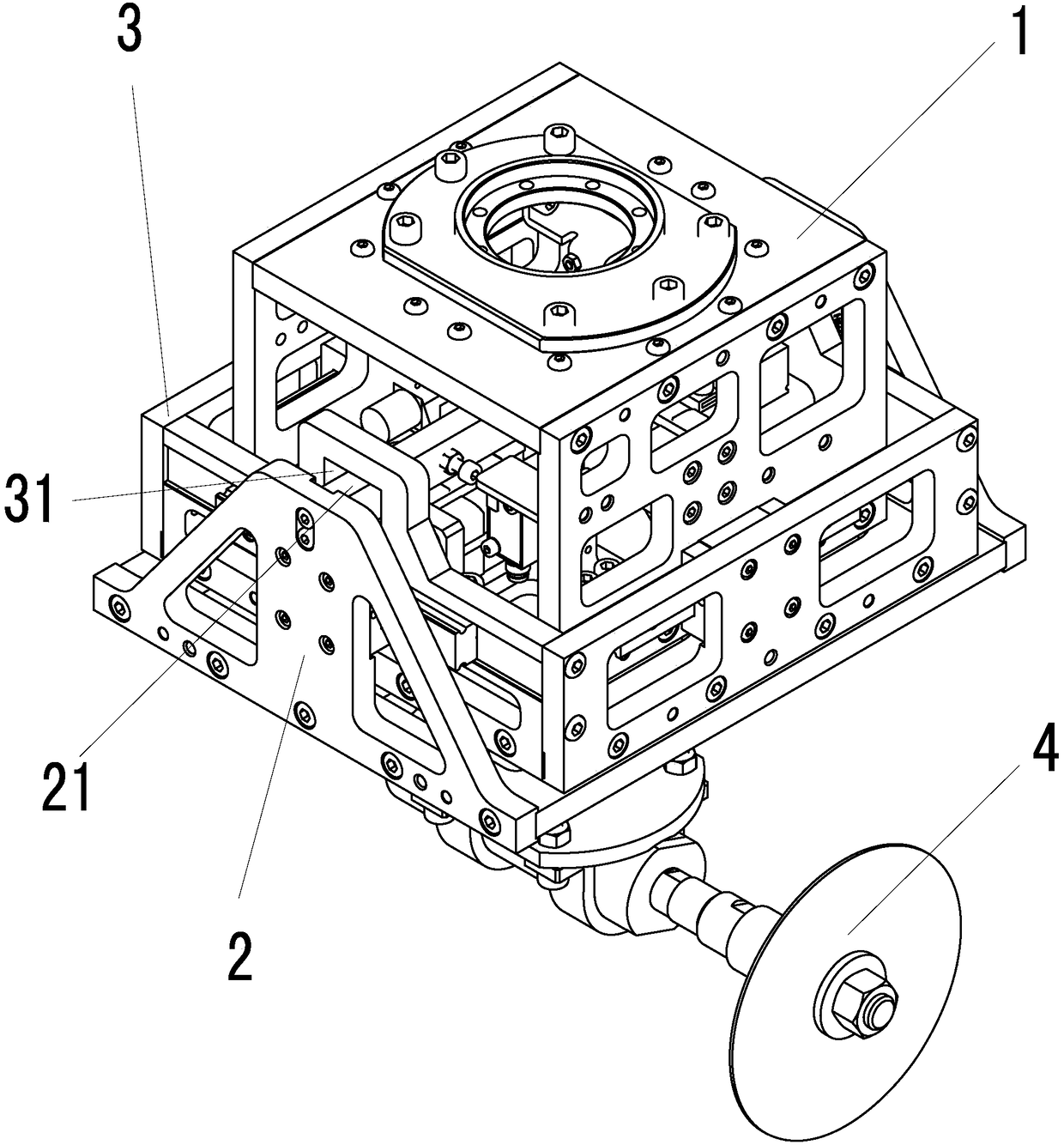

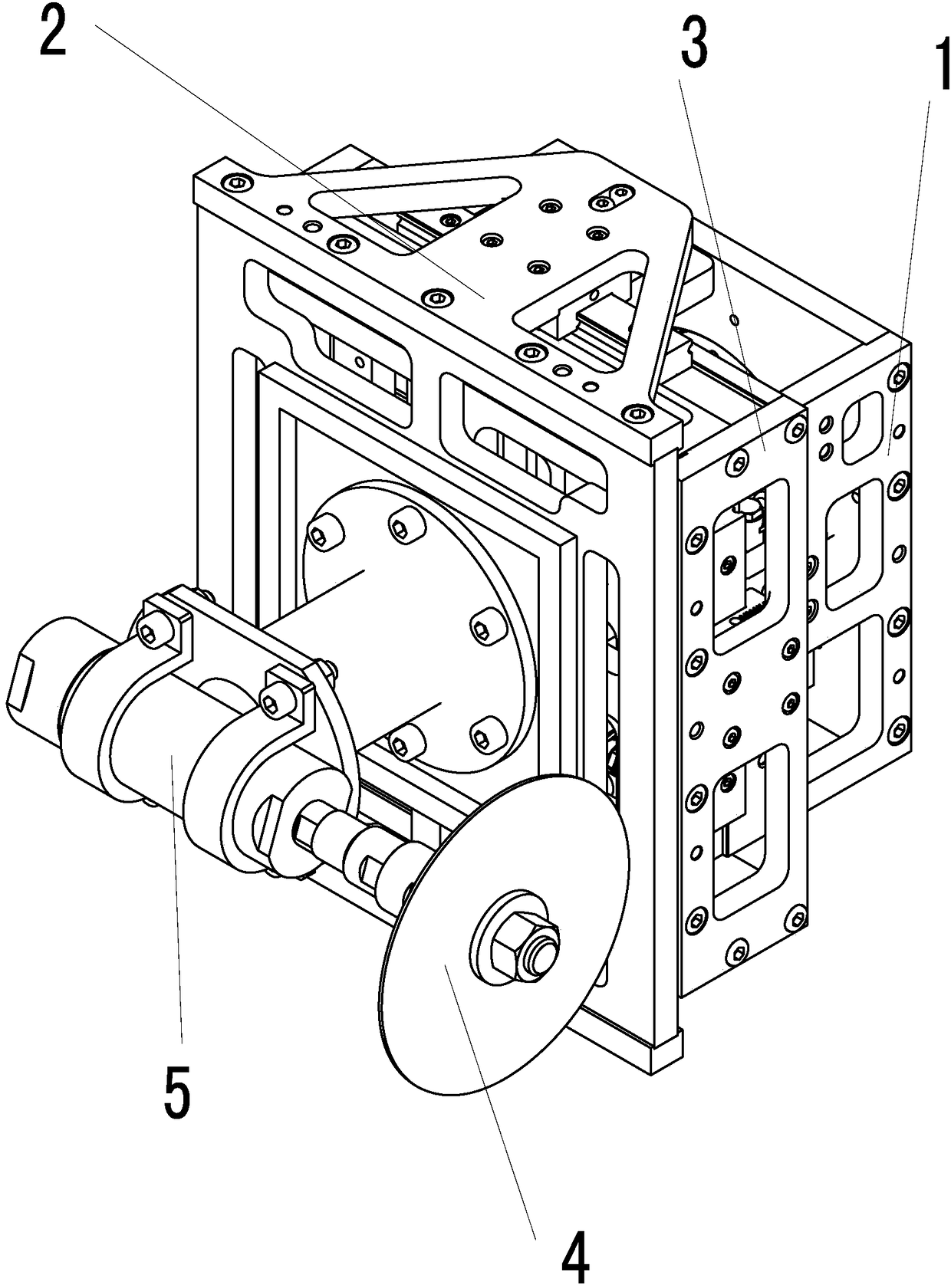

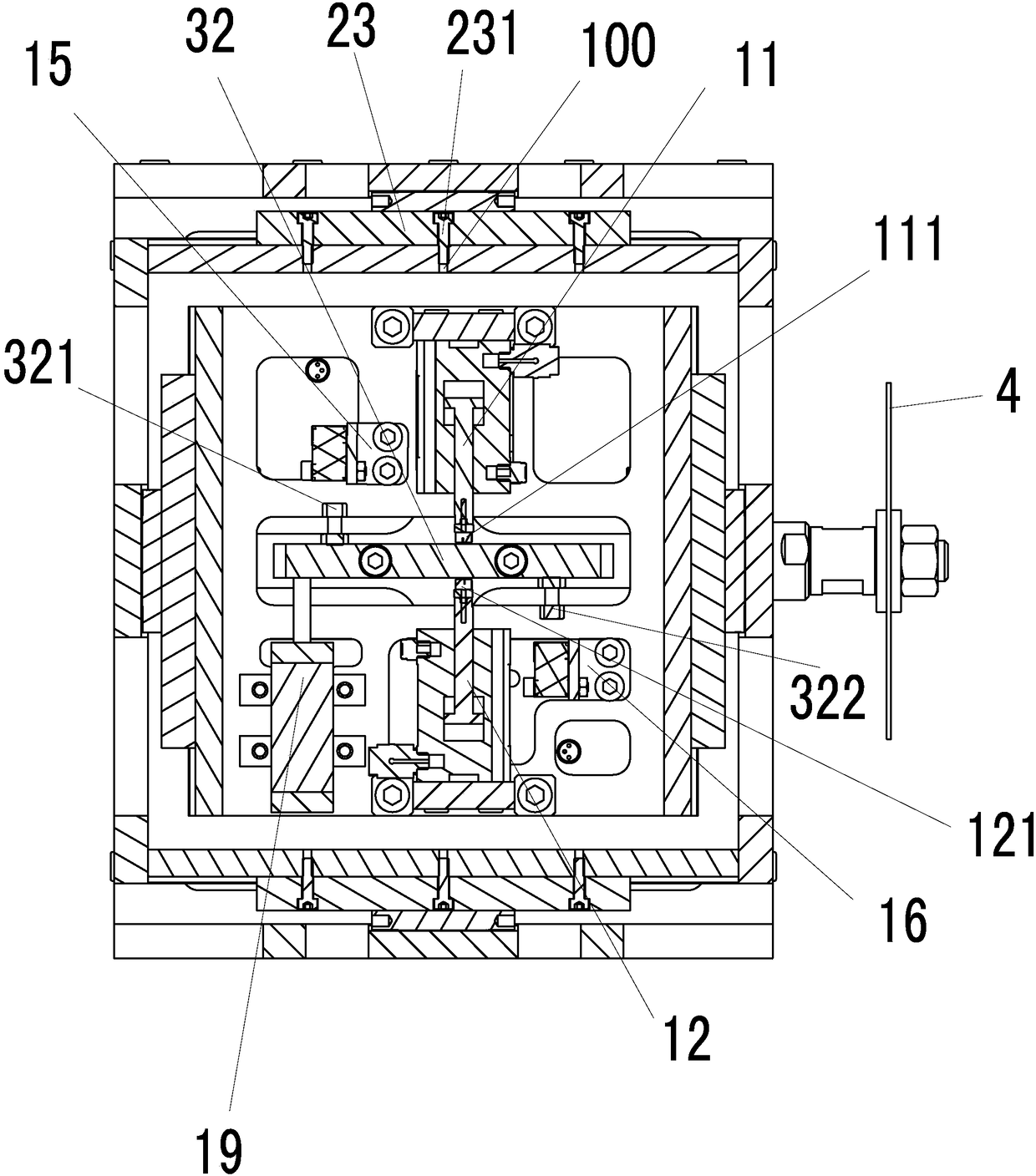

[0032] A grinding head device that precisely controls the amount of perception, refer to Figures 1 to 9 , comprising a housing frame 1, a moving bracket, and a controller; the housing bracket 1 and the moving bracket are respectively slidably connected along a first straight line direction and a second straight line direction; the first straight line is separated from the second straight line Set at a certain angle, in order to obtain the best working angle, the first straight line direction and the second straight line direction are perpendicular to each other;

[0033]The accommodating frame 1 is provided with a first drive assembly 11 and a second drive assembly 12 connected to the controller along the first linear direction, and the movement direction of the first drive assembly 11 and the second drive assembly 12 is opposite; The housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com