Material touch signal generator

A signal generator, signal transmitter technology, applied in the direction of instruments, engine components, liquid level indicators, etc., can solve the problem of reducing the reliability and stability of the weight detection type material level measuring device, and the reliability and stability have not been Very good improvement, unsatisfactory effect and other problems, to achieve the effect of improving reliability and operation stability, simple structure, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

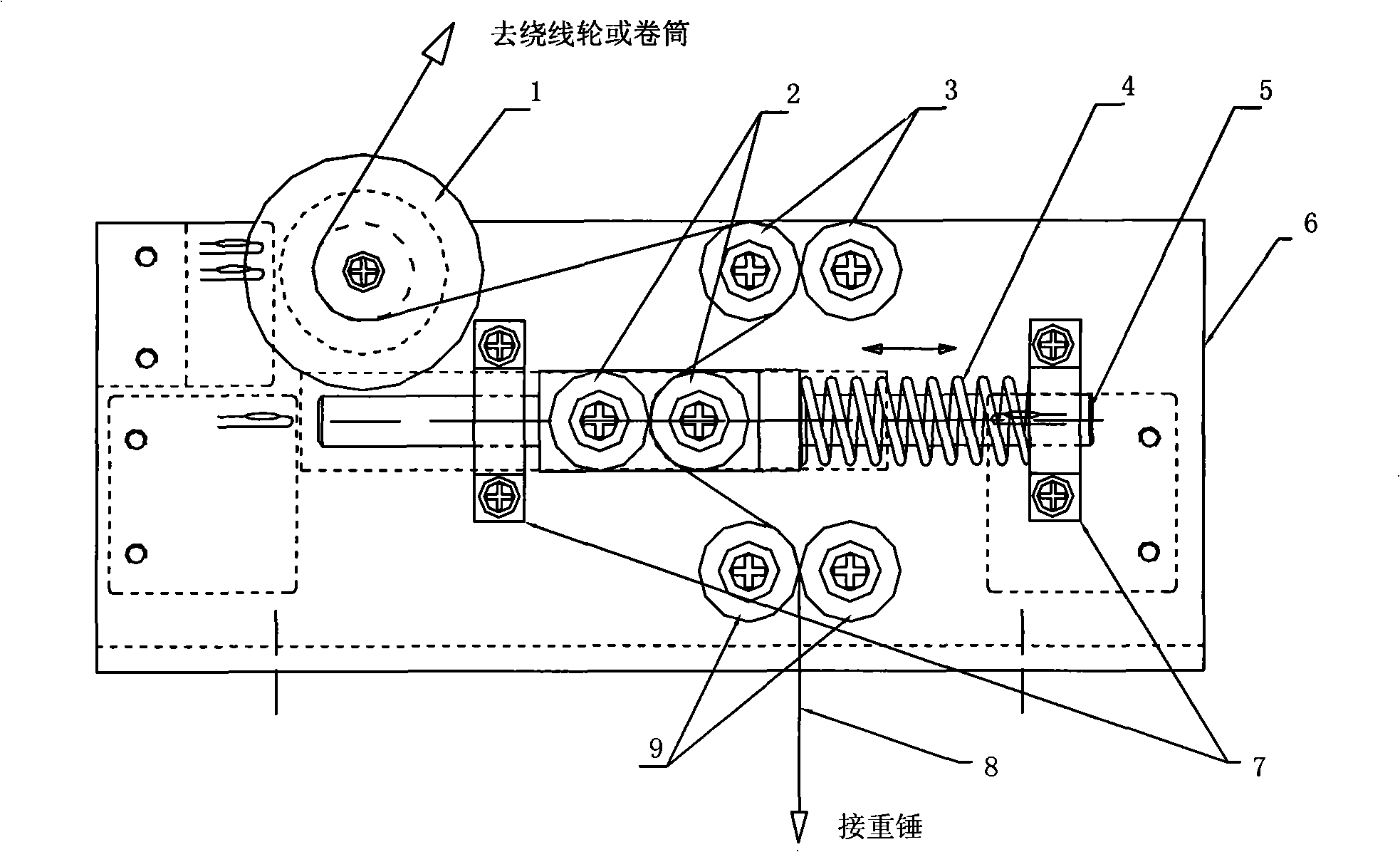

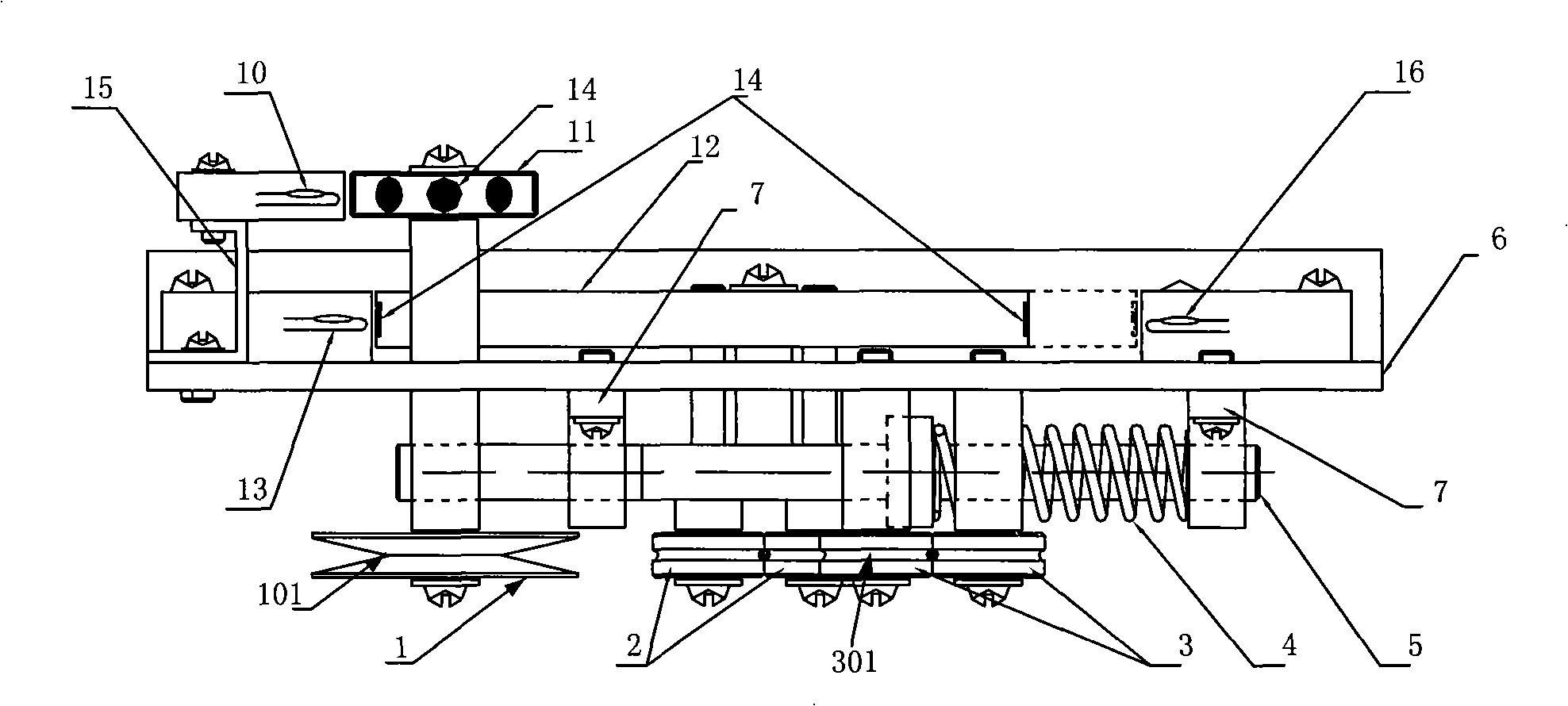

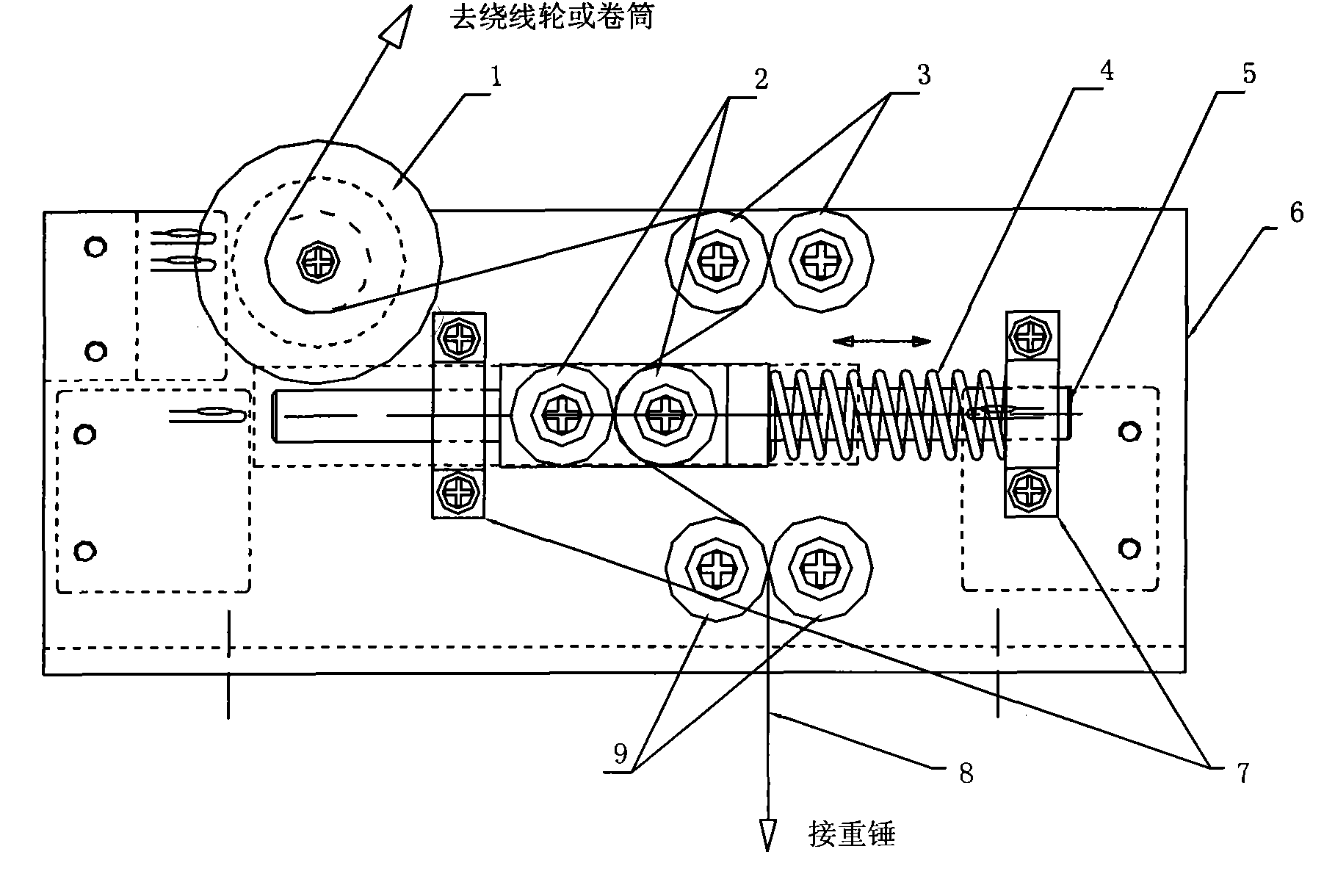

[0021] Such as figure 1 , figure 2 As shown, the contact signal generator provided by the present invention includes: measuring shaft wheel 1, elastic shaft wheel 2, upper guide shaft wheel 3, spring 4, contact rod 5, bracket 6, contact rod support 7, steel wire rope 8, Lower guide shaft wheel 9, material level pulse transmitter 10, pulse wheel 11, contact material block 12, contact material signal transmitter 13, magnetic steel 14, pulse signal transmitter bracket 15, buried hammer signal transmitter 16. The support 6 is a plate-like structure, a horizontal measuring shaft at the front end of the support 6 is perpendicular to the plane of the support 6, and the two ends of the measuring shaft are provided with a measuring shaft wheel 1 and a pulse wheel 11, which are respectively located on both sides of the support 6 and connected to the pulse wheel. 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com