Method for shredding food materials through metal wires

A metal wire and food material technology, applied in metal processing and other directions, can solve the problems of poor strength and durability, easy breakage, food extrusion and other problems, and achieve the effect of convenient maintenance and replacement, high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

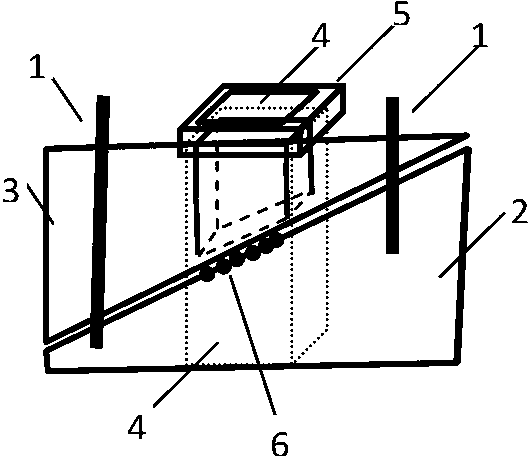

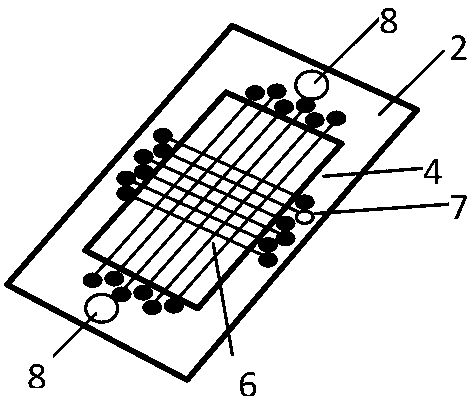

[0009] The method of shredding food materials by using metal wires is characterized in that: two upright columns with triangular or trapezoidal vertical sections overlap each other in the up and down directions to form a cuboid, and there is a vertical food material through hole 4 in the center of the cuboid, two The uprights are fixed by threaded screws or positioned by jack 8 and pin 1 (both methods are common techniques). For the convenience of description, the two uprights forming the cuboid are respectively called the lower support 2 and the upper support 3. The lower support A plurality of stainless steel wires 6 are fixed in parallel on the front and rear sides of the food material through hole 4 of the body 2, that is, the stainless steel wires 6 are horizontal, and at the same time, a plurality of stainless steel wires 6 are fixed in parallel on the left and right sides of the food material through hole 4 of the lower support body 2, two layers The planes where the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com