Ceramic line entire body feeding equipment and method

A cloth and line technology, which is applied in the field of ceramic line whole body cloth equipment, can solve the problems that cannot be done, can not fully reflect the delicate effect of stone stone lines, and cannot realize whole body lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

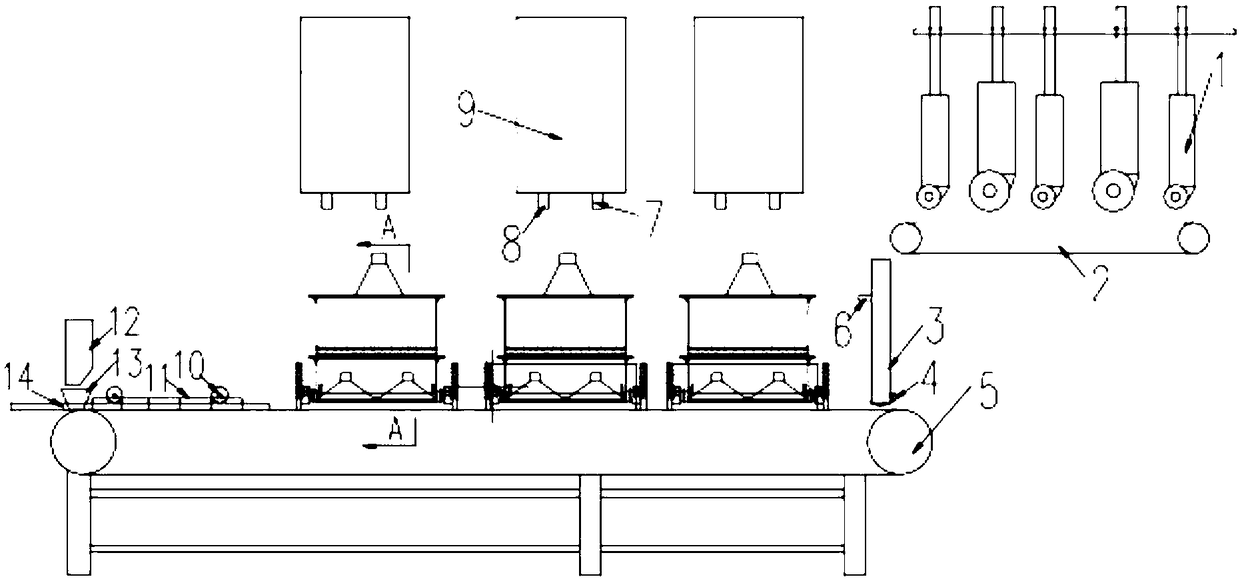

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing:

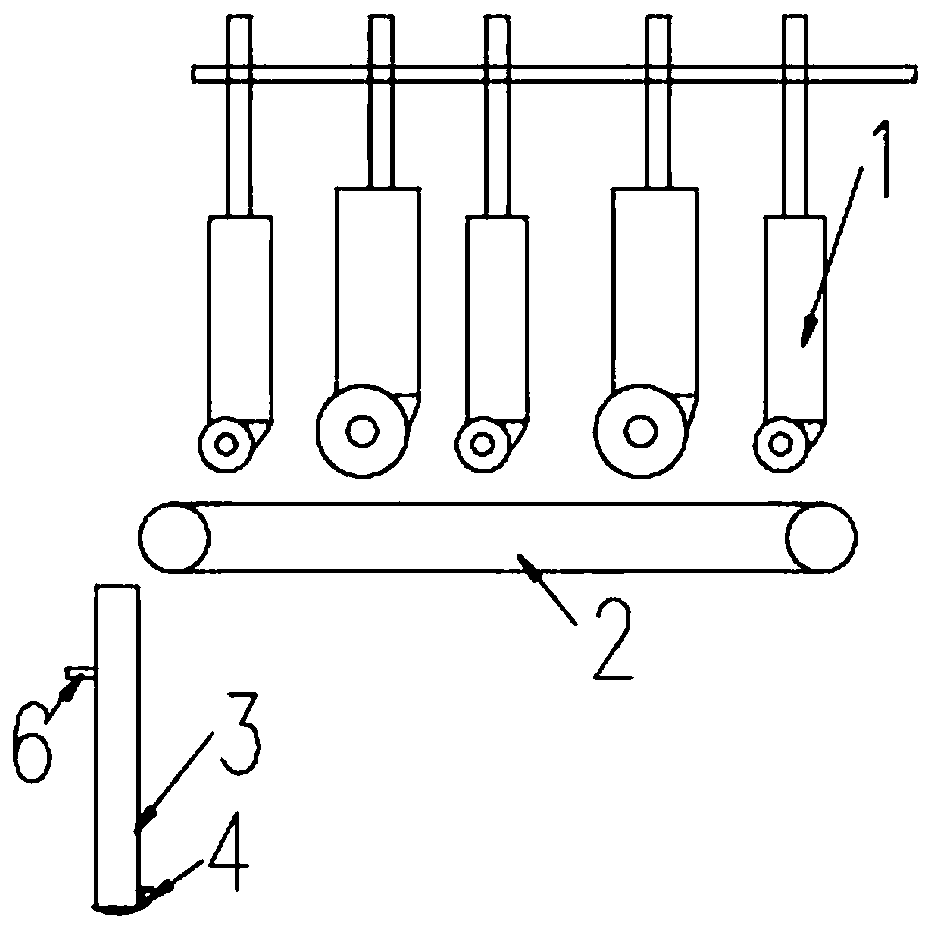

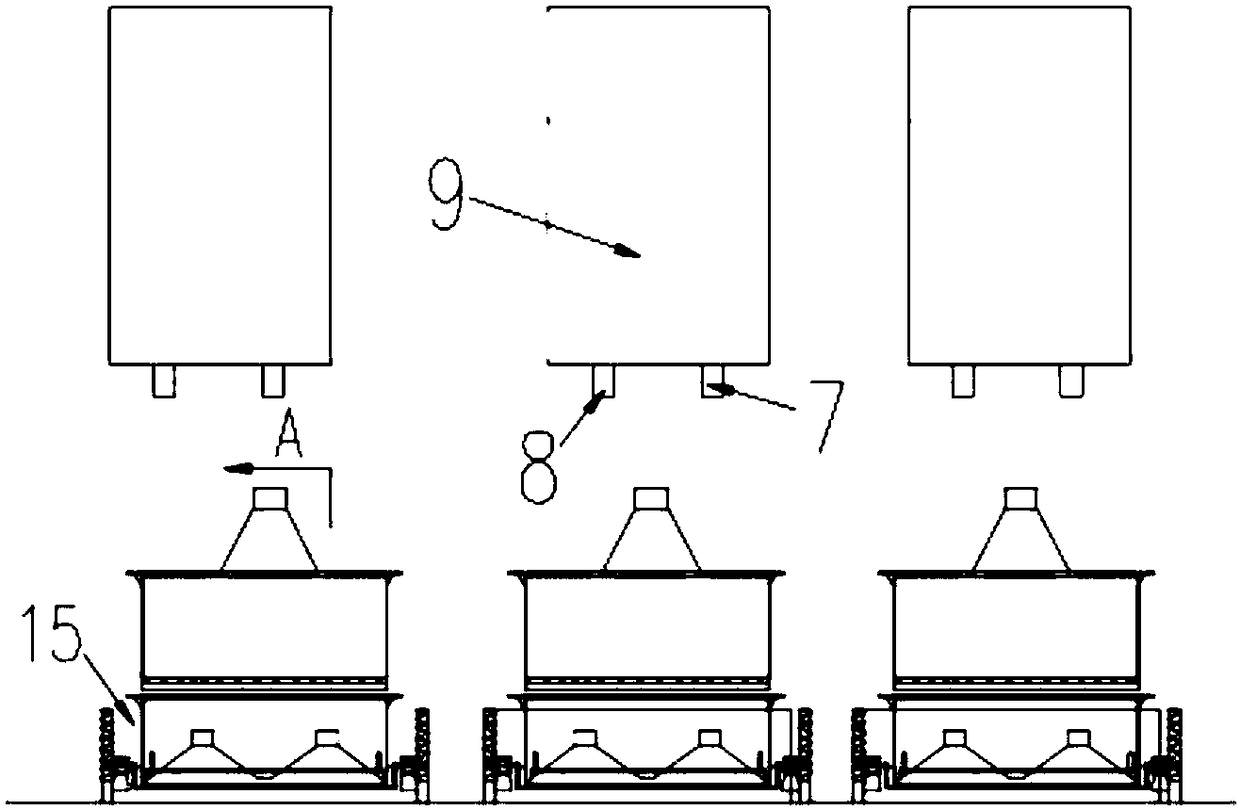

[0030] see Figures 1 to 6 As shown, the present invention provides a kind of whole-body distribution equipment for ceramic lines, which includes a basic texture pattern distribution mechanism, a whole-body line distribution mechanism, a circulation conveying module, and a feeding module. The cakes completed by the basic texture pattern distribution mechanism pass through the cycle The conveying module moves to the bottom of the whole-body line distributing mechanism to complete the distributing action of the whole-body line, and finally the conveying module is sent to the press for forming.

[0031] see figure 2 As shown, the basic texture pattern cloth mechanism includes a cloth belt 2, five blanking mechanisms 1 arranged along the horizontal direction of the cloth belt 2, and a transition glass box 3 arranged below the blanking end of the cloth belt 2. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com