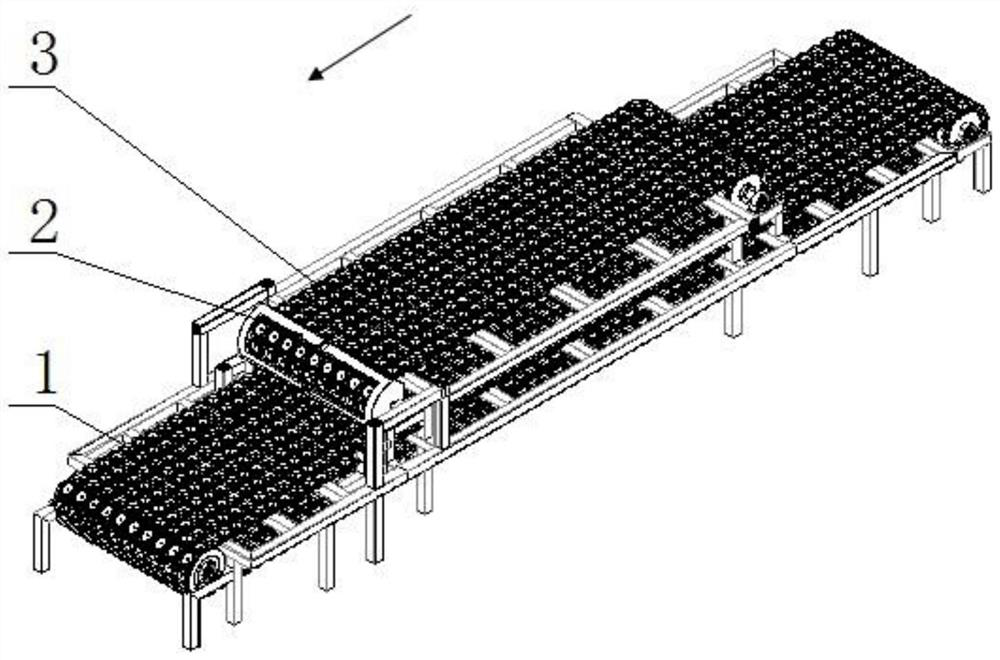

An automatic dish changing device

An automatic and petri dish technology, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of inconvenient picking and placing of petri dishes, and achieve the effects of saving manpower, high work efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The technological process of an automatic dish changing device is as follows:

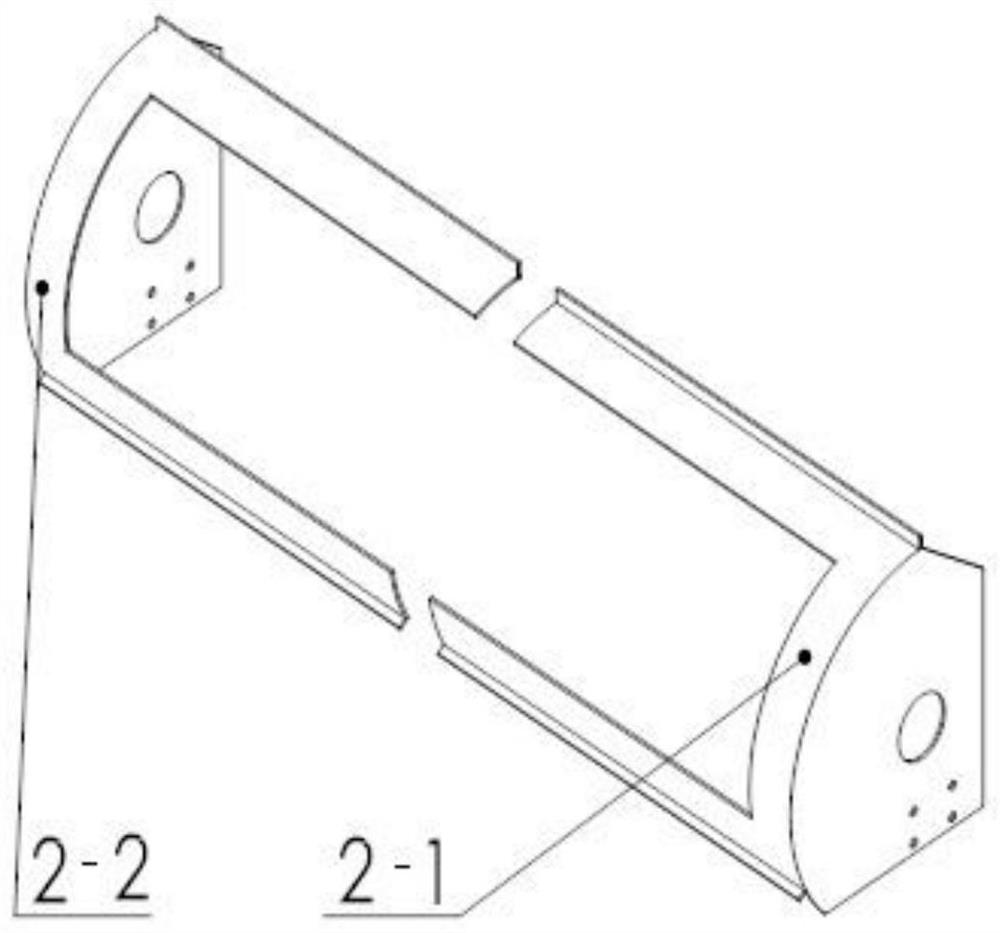

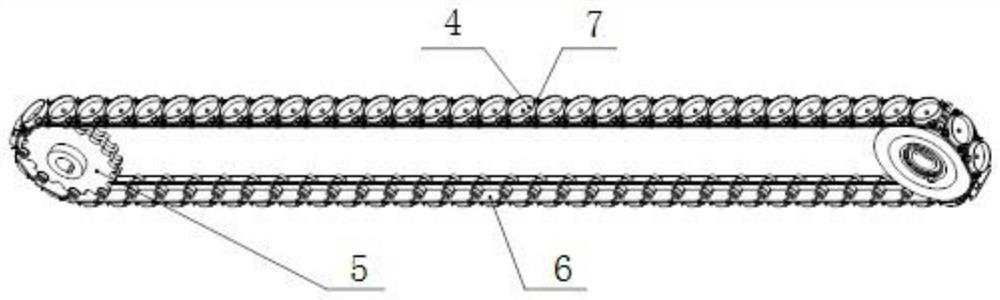

[0030] The petri dish that needs to be changed is clipped into the spring on the single-section chain plate on the upper petri dish fixed conveying chain plate 3 through the auxiliary equipment, and the fixed petri dish is fixed with the upper petri dish on the conveying chain board 3 way figure 1 The movement in the direction of the arrow is shown; when the petri dish moves to the anti-falling device 2 for changing the dish, because of the dumping process, the anti-falling device 2 for changing the dish with an elastic rubber film in the middle prevents the petri dish from falling off. The material in the petri dish falls off without being aligned with the lower layer of the petri dish after cleaning; then the loaded petri dish and the items in it smoothly pass through the falling arc at the 2 place of the anti-dropping device for changing the dish, and are fixed with the lower petri dish a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com