Walk-in type material circulation cart

A turnover car, walk-in technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of inability to connect with three-dimensional warehouse equipment, insufficient conveying positioning accuracy, cumbersome operation, etc., and achieve convenient feeding. , The effect of easy operation and high clearance accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

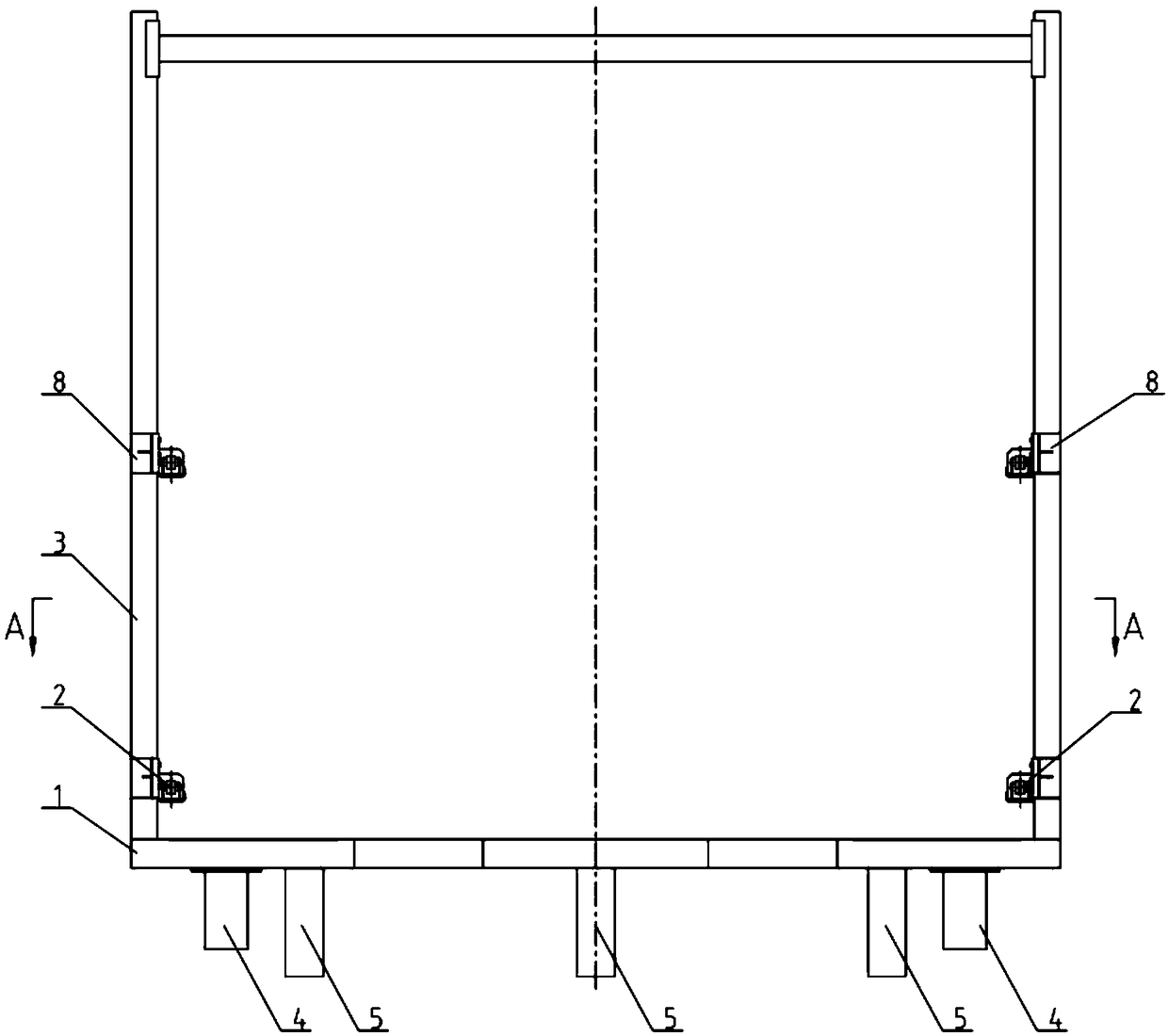

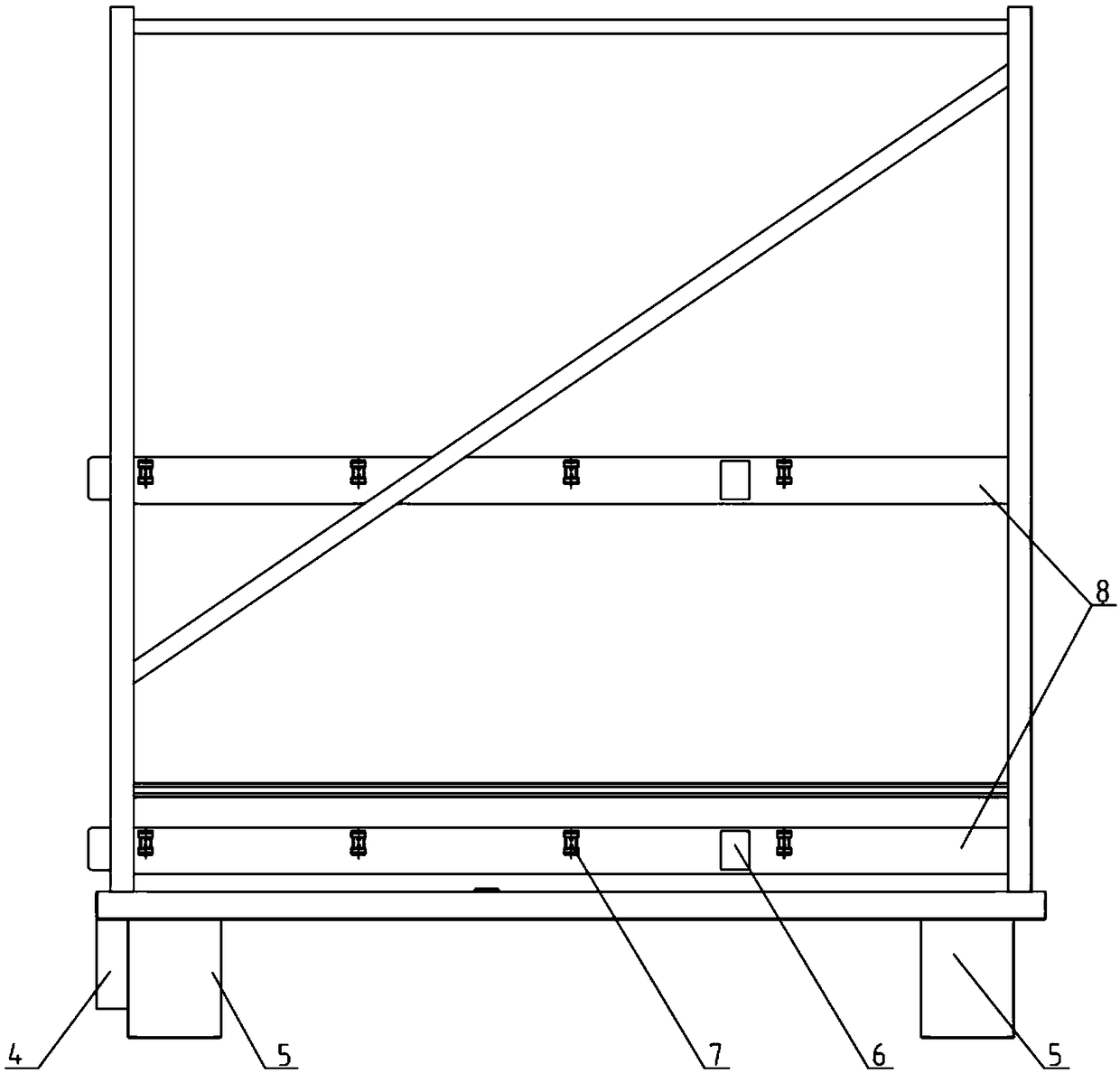

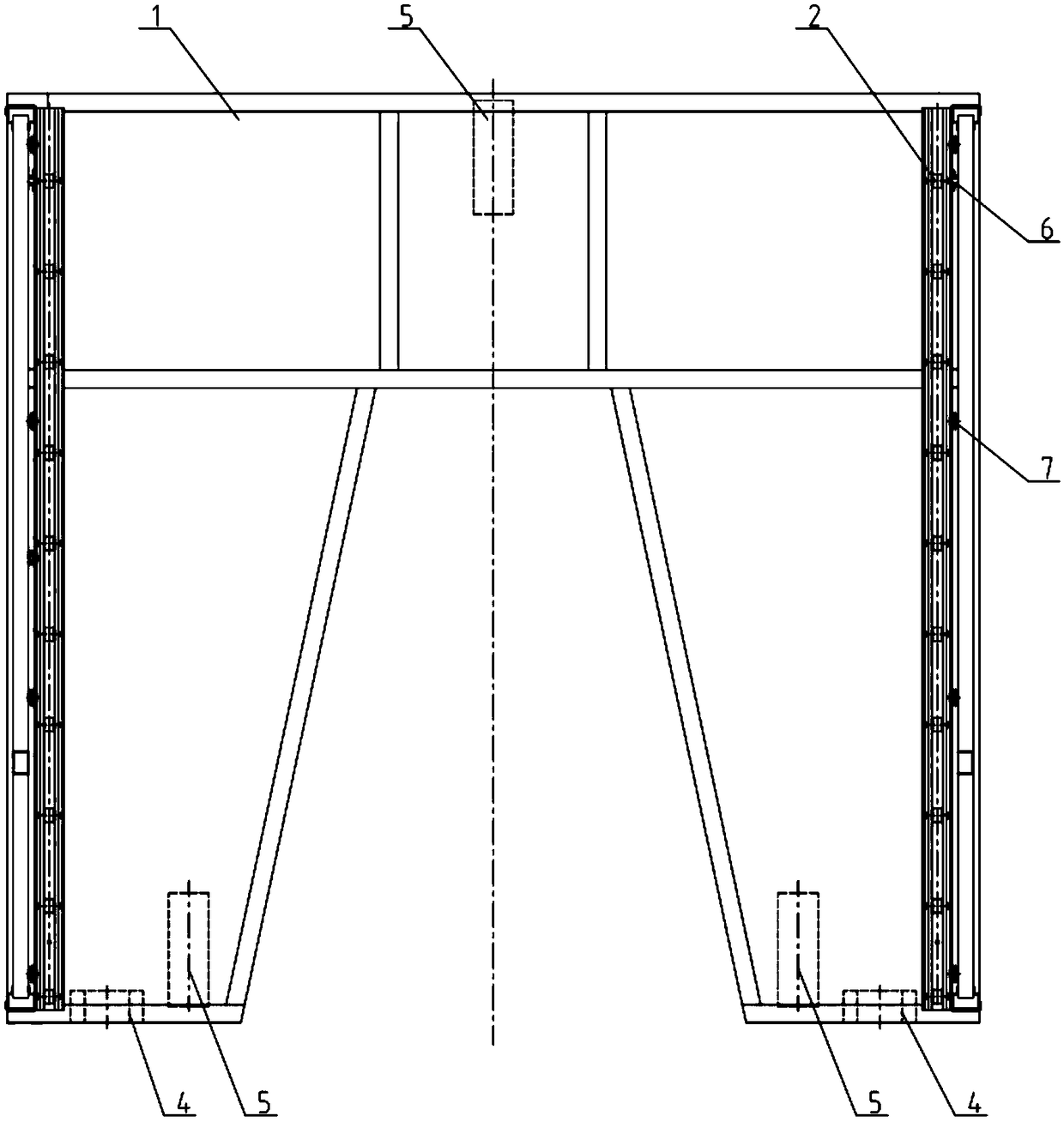

[0029] As shown in the figure, the present invention discloses a walk-in material turnover vehicle, which includes a chassis 1, a column 3 and traveling wheels 5, and tray brackets 8 are installed on the columns 3 on both sides of the walking direction. A pallet support mechanism 2 is installed, and the frame of the chassis 1 and the column 3 has a gap that can be stepped into on one side of the walking direction, and goods and operators enter and exit through the gap.

[0030] The walk-in material turnover vehicle also includes a warehousing guide mechanism 4 installed under the chassis 1 to cooperate with the guide on the ground, and 9 sets of bearings 9 are installed on the pallet support mechanism 2, the central axis 10 of the bearing 9 is horizontal, and the outer Ring 11 and the tray bottom rolling friction. The tray bracket 8 is equipped with a tray side guide mechanism 7 on the side wall of the movement track of the tray in and out, which are four sets of bearings 9, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com